Cement based penetrative crystallized mortar waterproofing agent and its preparation

A penetrating crystallization, cement-based technology, applied in the field of cement mortar waterproofing admixtures for construction, can solve the problems of short validity period of waterproof layer, difficulty in permanent waterproofing, etc., and achieve the effect of improving crack resistance and deformation ability and improving toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

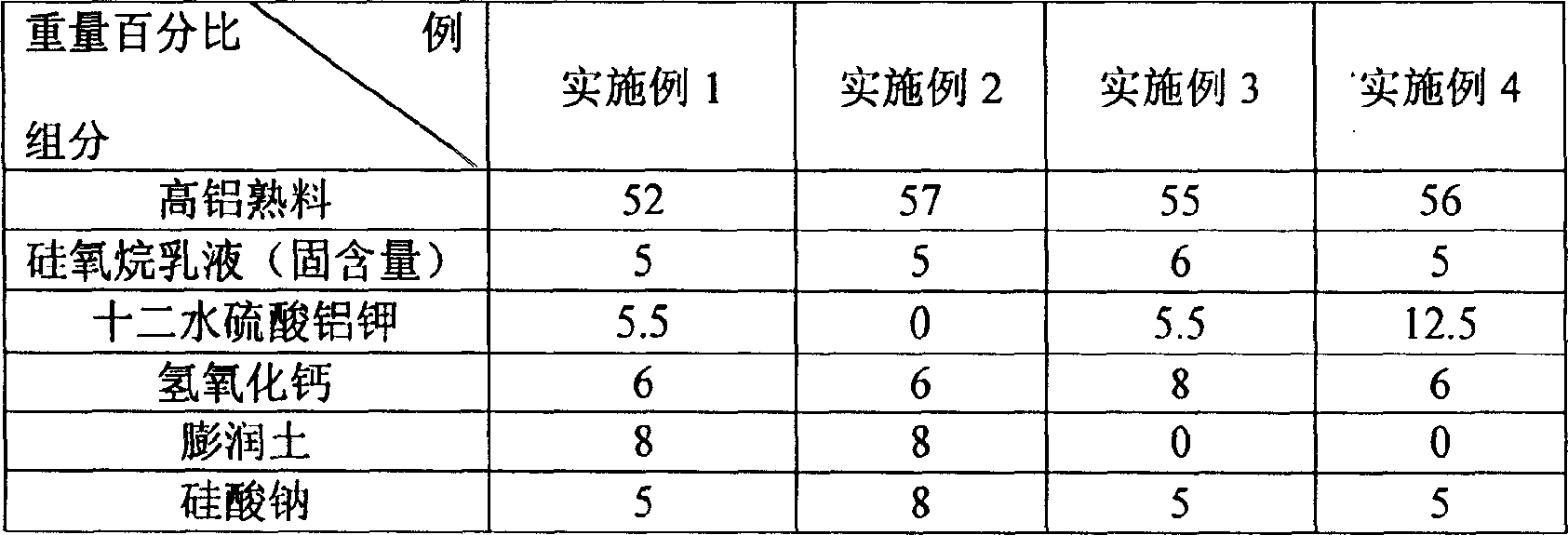

[0039] According to the above-mentioned ratio and the above-mentioned preparation method, high-performance cement-based permeable crystalline mortar waterproofing agents with slightly different performance requirements can be prepared for different occasions.

[0040] The dosage of the waterproofing agent is 5-7% (mass ratio) of cement in the mortar, and the water-cement ratio is controlled at 0.35-0.5. After weighing according to the proportion, stir with a mixer according to the regulations, and the stirring time is not less than 3 minutes to ensure that it is fully stirred and evenly mixed. The thickness of the mortar waterproof layer is generally 20-25mm. It must be scraped and pressed in 2-3 times, each time with a thickness of about 7-9mm. It can also be carried out according to the waterproof design requirements. After the mortar is added with water, it forms a thixotropic, fluid slurry, and the active ingredients penetrate into the interior of the concrete and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com