Air exhaust pwrifying filter catalyst

A filter and catalyst technology, applied in the direction of physical/chemical process catalysts, catalyst carriers, filtration and separation, etc., can solve the problems of DPF damage, etc., and achieve the effects of improved oxidation activity, increased contact area, and excellent temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

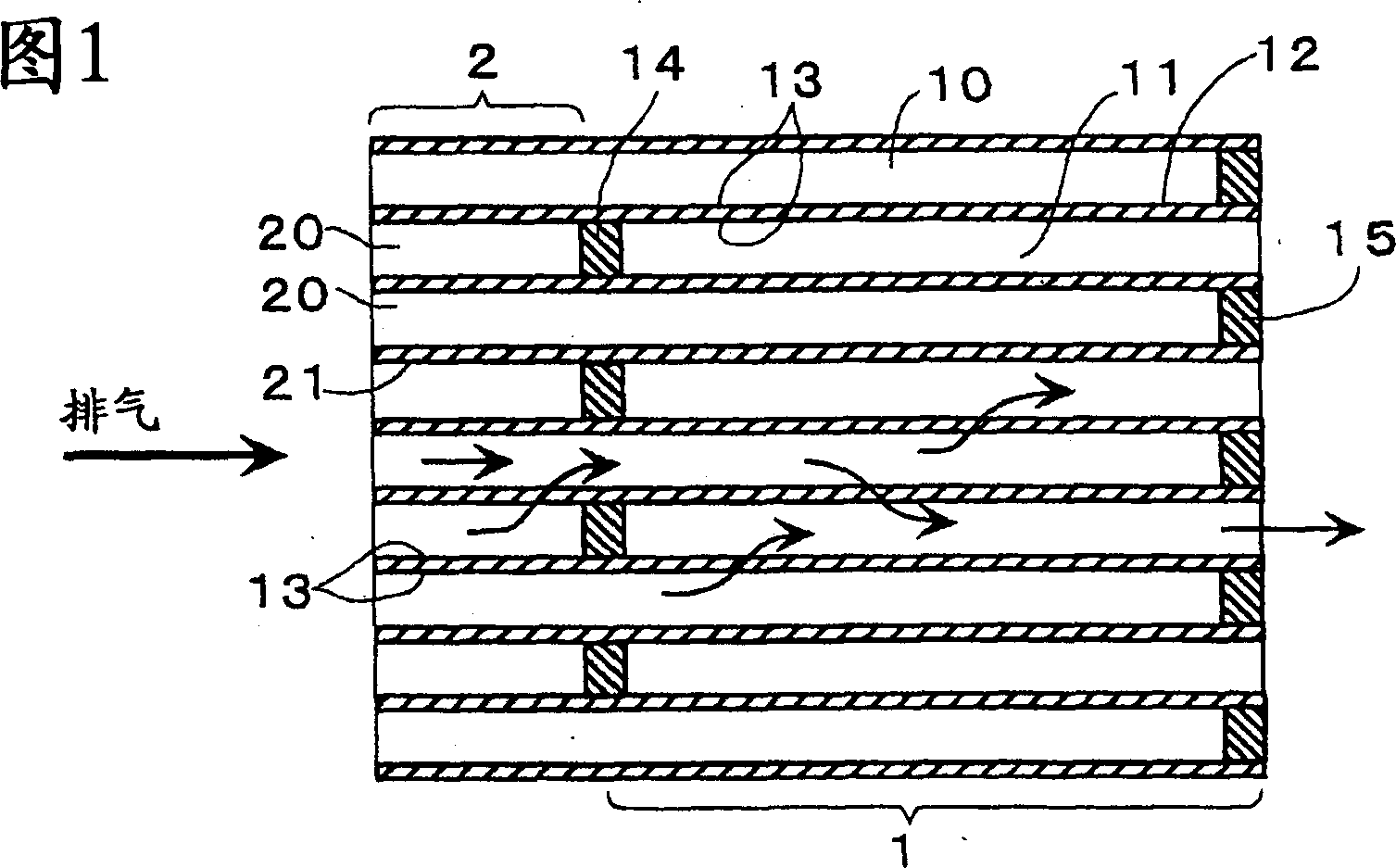

[0055] FIG. 1 is a cross-sectional view showing a main part of the exhaust gas purification filter catalyst of this embodiment. This exhaust purification filter catalyst includes a wall flow honeycomb structure portion 1 and an upstream side direct current honeycomb structure portion 2 integrally formed with the exhaust gas upstream side of the wall flow honeycomb structure portion 1 .

[0056] The wall-flow honeycomb structure part 1 includes an inflow-side cell 10 blocked on the exhaust gas downstream side, an outflow-side cell 11 adjacent to the inflow-side cell 10 and blocked on the exhaust gas upstream side, separating the inflow-side cell 10 and the outflow cell. The filter partition wall 12 of the side compartment 11 and the catalyst layer 13 formed on the surface of the filter partition wall 12 . In addition, the upstream straight-flow honeycomb structure part 2 includes the upstream straight cells 20 , the upstream cell partition walls 21 for partitioning the upstream...

Embodiment 2

[0064] Except that on the catalyst layer 13 of the upstream straight-flow honeycomb structure portion 2, 5 g of Pt was loaded per 1 liter volume of the upstream straight-flow honeycomb structure portion 2, but Li, Ba, and K were not loaded, the same as in Example 1. composition.

[0065] In this example, the oxidation activity in the upstream side direct flow honeycomb structure portion 2 was greatly improved compared with Example 1. Thus, the heat retention property of the intermediate plug 14 and the temperature rise property of the wall flow honeycomb structure portion 1 are further improved. (Example 3)

Embodiment 3

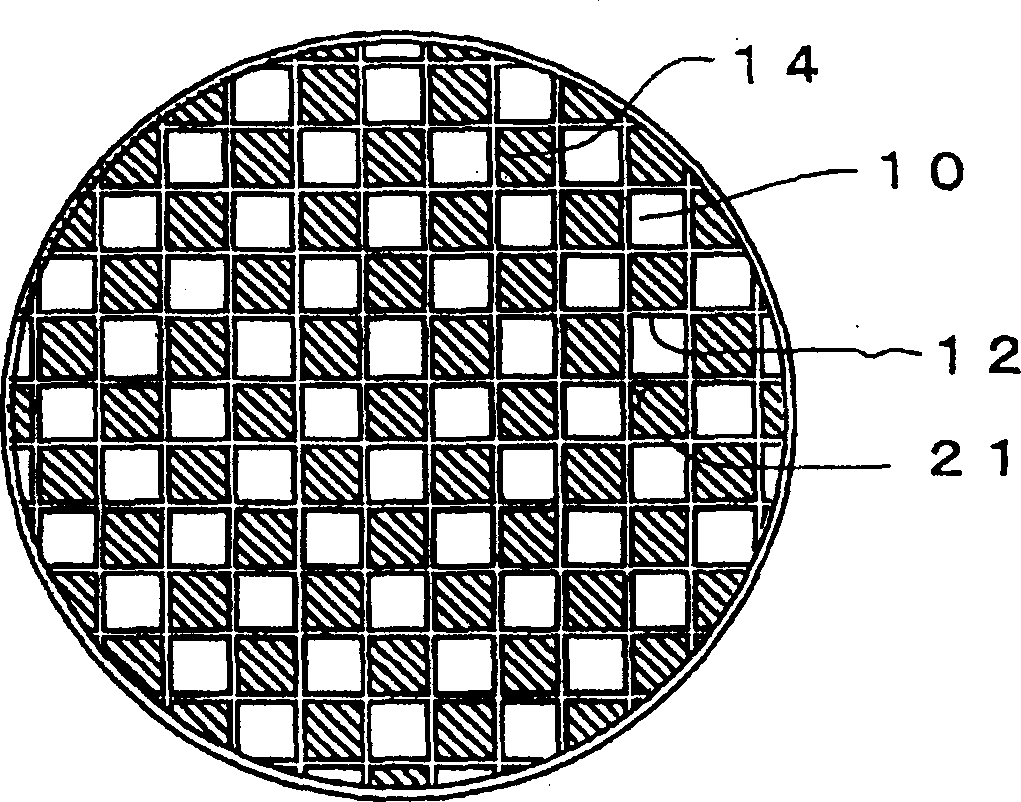

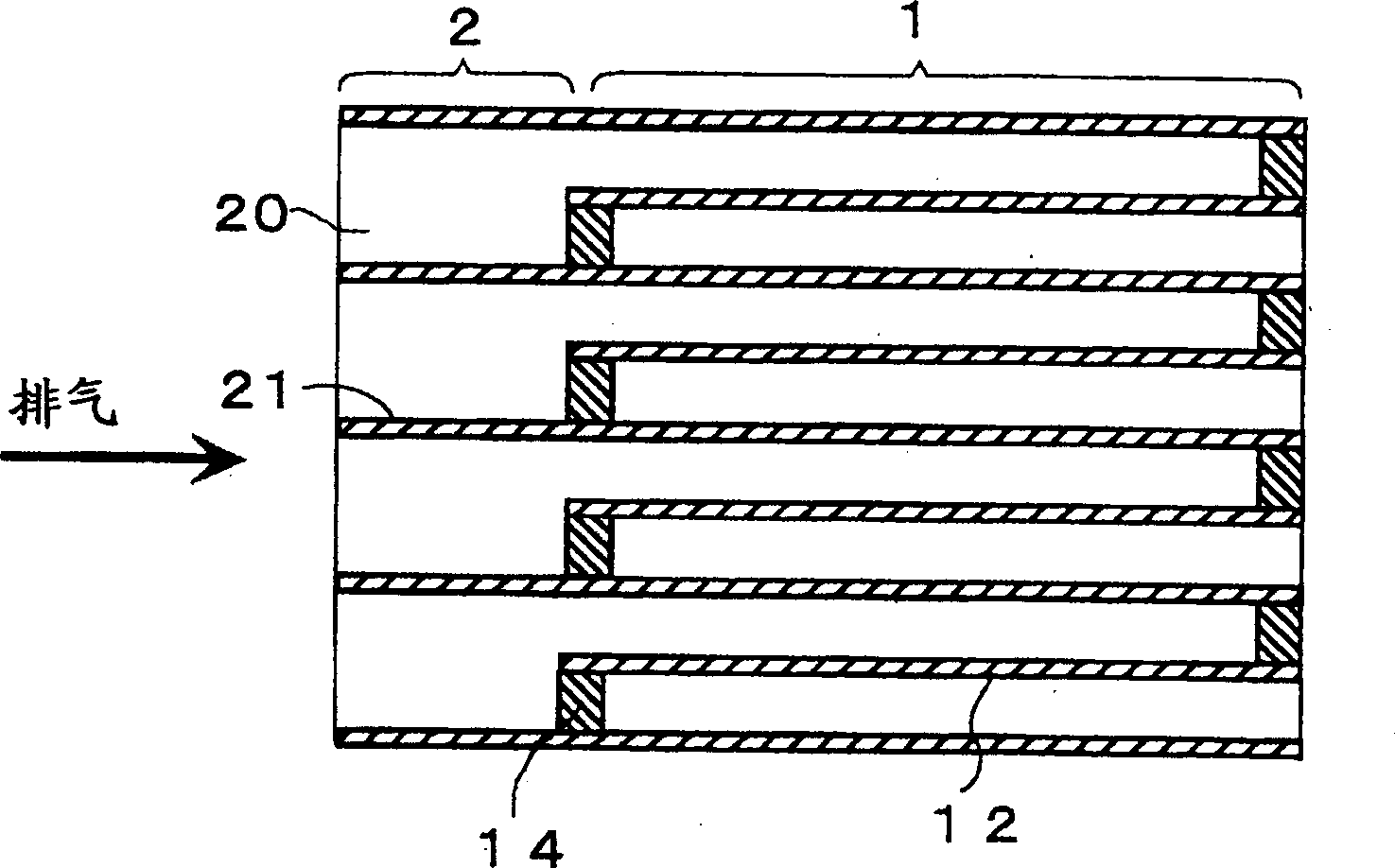

[0066] figure 2 A front view showing the inflow-side end face of the exhaust purification filter catalyst of this embodiment, image 3 A sectional view showing its main parts. This exhaust purification filter catalyst has the same configuration as that of the first embodiment except that every other upstream compartment partition wall 21 is cut to the position of the intermediate plug 14 .

[0067] In this embodiment, the temperature-rising exhaust gas easily comes into contact with the surface of the intermediate plug 14 by the reaction in the upstream-side straight-flow honeycomb structure portion 2, and since the upstream-side opening of the intermediate plug 14 becomes larger, it is difficult to further cause PM to The surface of the intermediate plug 14 builds up. Thus, clogging of the upstream straight compartment 20 can be further suppressed.

[0068] In this embodiment, the intermediate plug 14 is formed in the same manner as in the first embodiment, but the interme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com