Multiple sensor integrated intelligent transparent container detecting device and method

A multi-sensor fusion and transparent container technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of high missed detection rate, low precision, slow speed, etc., and achieve the effect of improving productivity, fast detection speed, and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

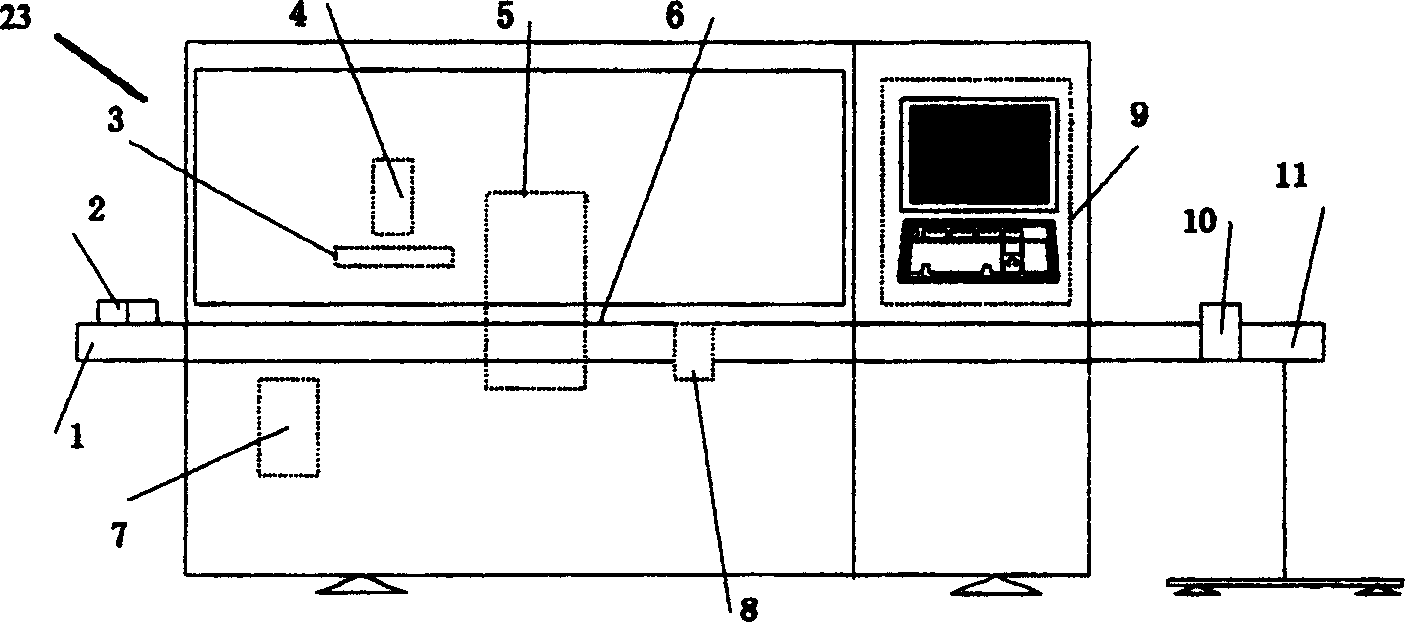

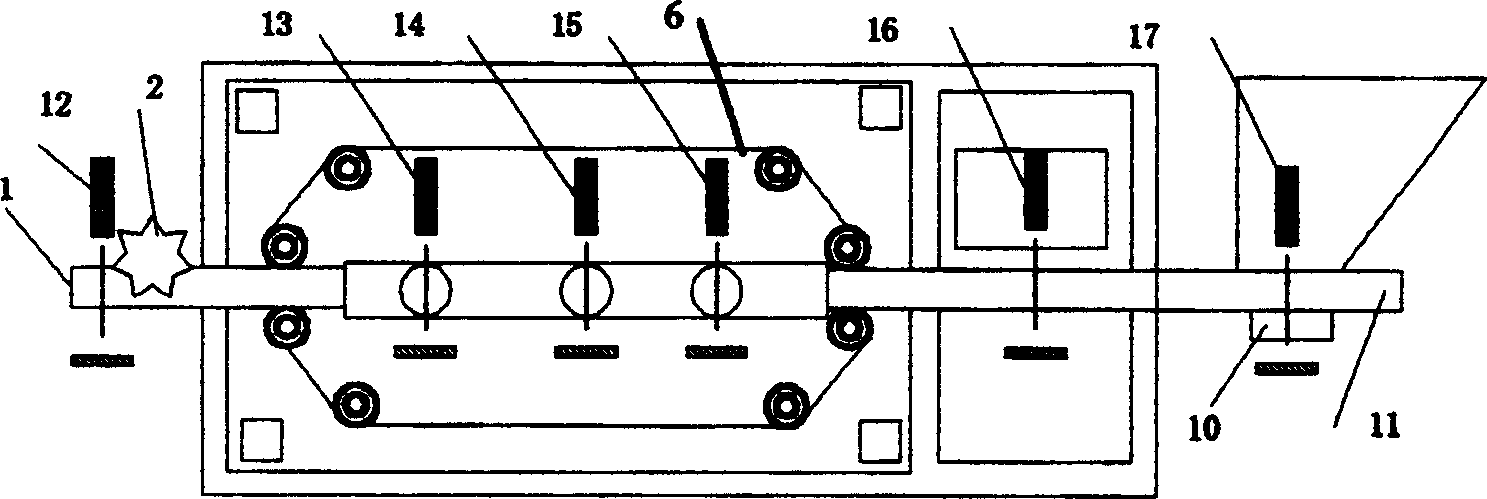

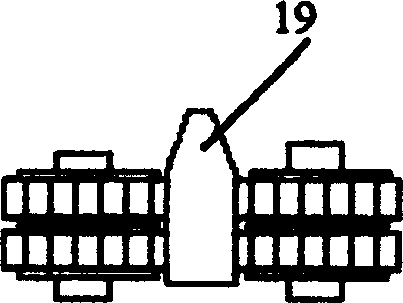

[0020] Examples of the present invention are figure 1 , figure 2 As shown, it mainly includes two parts: a detection system and an electrical control system, wherein the detection system includes a box body 23, a container separation machine 2, a container input port, a container port light source 3, a container port camera 4, a container bottom detection module 5, and a container conveyor belt 6 , the container bottom cleaner 7 installed in the box body 23, the residual liquid detection module 8, the container side detection module 9, the defective container ejector 10 installed at the container outlet, the container output port 11, the container installed in the box Photoelectric sensors 13, 14, 15, 16, 17 and a photoelectric sensor 12 installed at the container separator 2;

[0021] The container input port 1 is connected with the conveyor belt of the assembly line, and the separating container machine 2 is installed at the container input port 1 to separate the container...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com