Method of gasoline desulfurization

A gasoline and heavy gasoline technology, applied in the petroleum industry, processing hydrocarbon oil, refining hydrocarbon oil, etc., can solve the problems of reducing total sulfur, exceeding gasoline index requirements, low reaction temperature, etc., and achieving the effect of no loss of octane number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

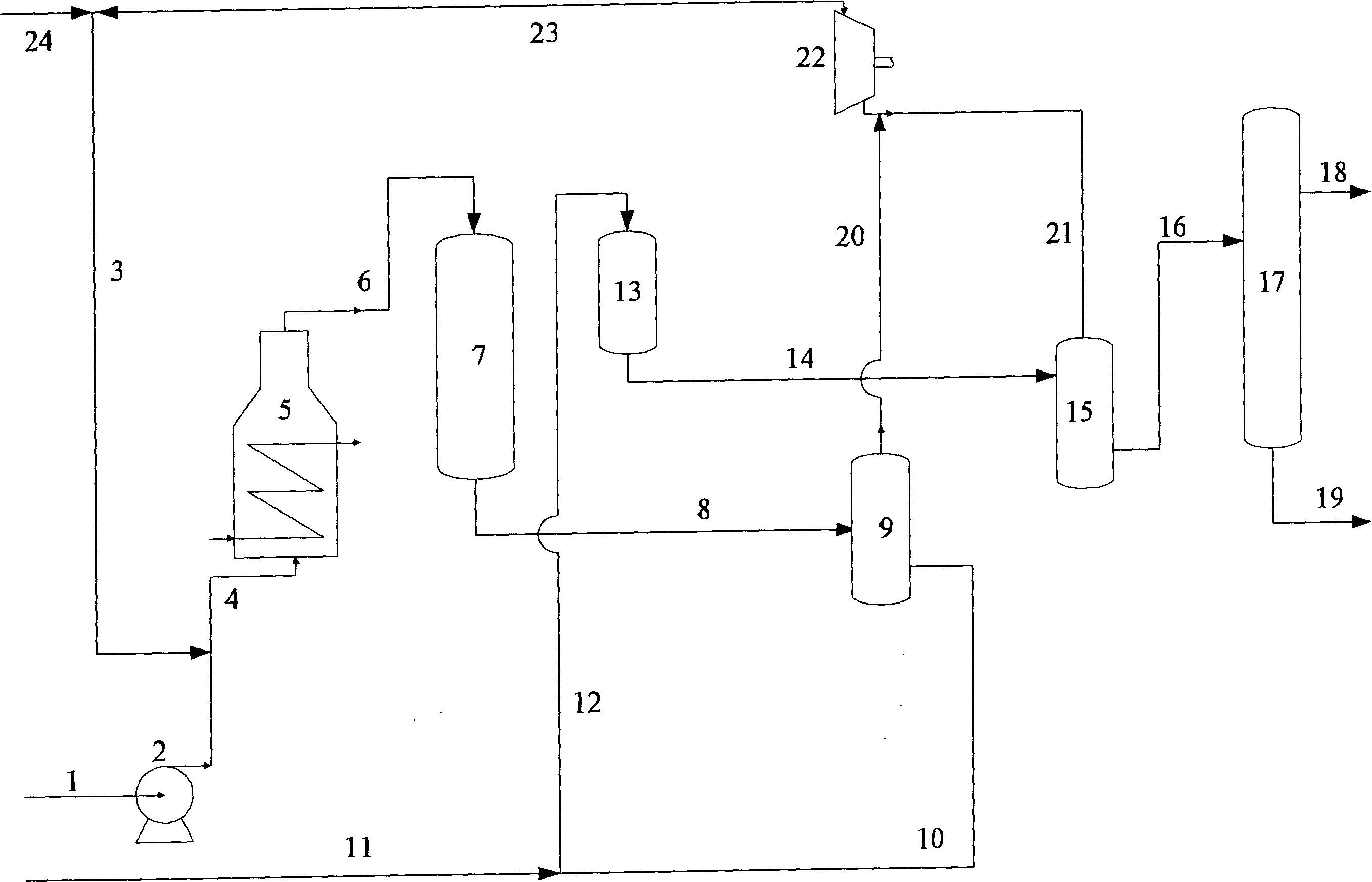

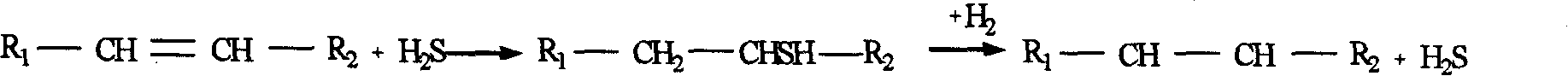

Method used

Image

Examples

Embodiment 1

[0031] Using FCC gasoline A as the raw material, the raw material is cut first, and the resulting heavy gasoline fraction and hydrogen are contacted with the catalyst RSDS-1 at a hydrogen partial pressure of 1.6MPa, a reaction temperature of 290°C, and a liquid hourly space velocity of 4.0h -1 , hydrogen oil ratio 400Nm 3 N m 3Carry out hydrodesulfurization under the condition; Different from the comparative example, the effluent of the hydrodesulfurization reaction goes to hydrodemercaptan instead of oxidative sweetening, and the effluent of the hydrodesulfurization reaction passes through the cold high-pressure separator to separate the gas phase, The remaining liquid phase is mixed with new hydrogen and then contacted with the catalyst RSS-1A, and the effluent enters the high-pressure separator and the stabilization tower in turn to obtain qualified products; the hydrogen-rich gas separated from the high-pressure separator is boosted by the circulating compressor and then r...

Embodiment 2

[0033] Using FCC gasoline B as the raw material, the raw material is cut first, and the obtained heavy gasoline fraction and hydrogen are contacted with the catalyst RSDS-1 at a hydrogen partial pressure of 1.6MPa, a reaction temperature of 300°C, and a liquid hourly space velocity of 4.0h -1 , hydrogen oil ratio 400Nm 3 / m 3 Hydrodesulfurization is carried out under certain conditions; after the effluent of the hydrodesulfurization reaction passes through the cold high-pressure separator to separate the gas phase, the remaining liquid phase is mixed with new hydrogen and then contacted with the catalyst RSS-1A, and the effluent enters the high-pressure separator, Qualified products are obtained from the stabilizing tower; the hydrogen-rich gas separated from the high-pressure separator is boosted by a circulating compressor and then returned to the hydrotreating reactor for recycling. The properties of the distillate after hydrodesulfurization are shown in Table 1, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com