Arc electrodes for synthesis of carbon nanostructures

A technology of carbon nanostructures and arc electrodes, applied in nanostructure manufacturing, nanotechnology for information processing, nanotechnology for materials and surface science, etc., can solve problems such as waste and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

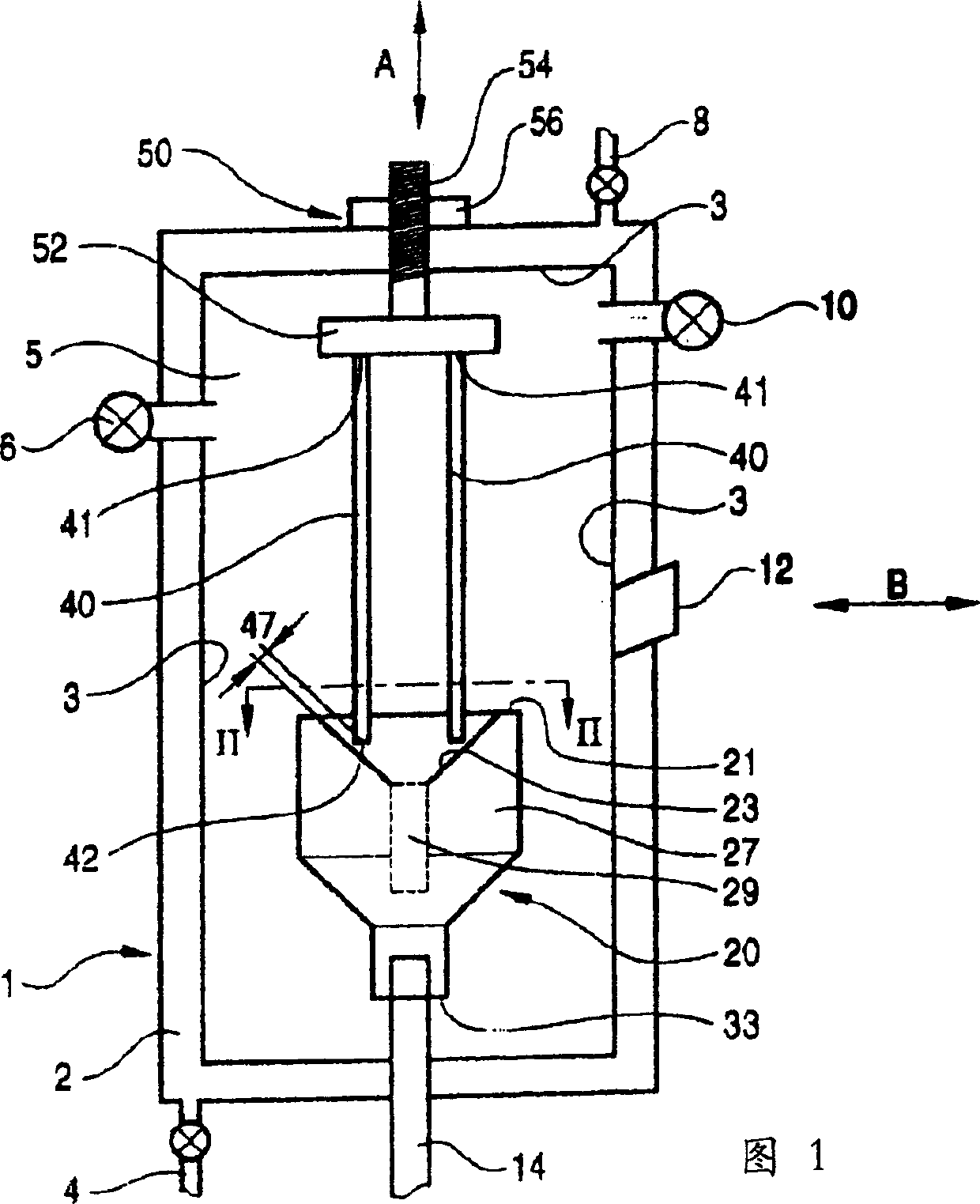

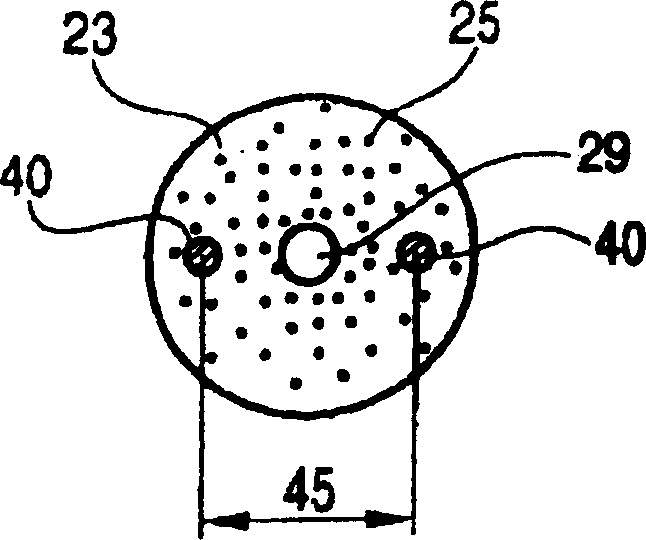

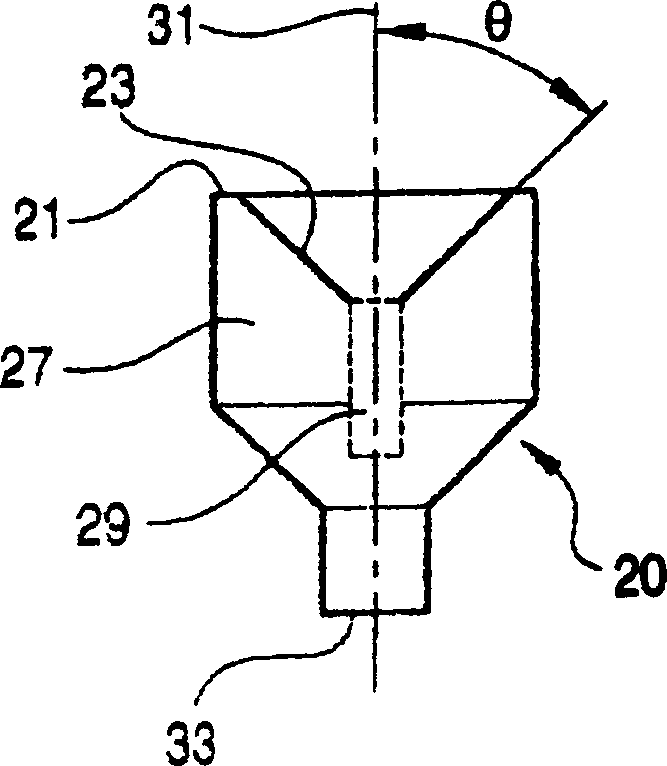

[0019] 1-3 show a first embodiment of the present invention. The device for manufacturing carbon nanostructures includes a chamber 1 , a first electrode 20 , or a plurality of second electrodes 40 , and an adjustment mechanism 50 .

[0020] The chamber 1 comprises a wall 2 surrounding a chamber interior 5 . Wall 2 is configured to allow cooling fluid to flow therethrough. A cooling fluid can be led through the cooling fluid inlet 4 and out of the cooling fluid outlet 8 in order to cool the chamber interior 5 . In addition, the chamber 1 comprises an inlet 6 and an outlet 10 so that a gas protective atmosphere can be formed inside the chamber interior 5 . A protective gas atmosphere includes any inert gas such as, for example, helium or argon. Additionally, the protective gas atmosphere may include hydrogen or a mixture of hydrogen and an inert gas, and is typically at a pressure of from about 300 Torr to about 760 Torr. The specific composition of the gas protective atmosp...

no. 2 example

[0045]A second embodiment of the invention is shown in FIG. 4 . Components that are the same as those illustrated and described in the first embodiment are given the same reference numerals, and therefore, descriptions of such components are omitted here.

[0046] In this embodiment of the invention, the chamber 1 comprises an outlet pipe 16 , a collection tank 18 , and a pump 19 . The outlet tube 16 is connected to the first electrode 20 and the collection tank 18 . The collection tank 18 is in turn connected to a pump 19 . Additionally, the first electrode 20 includes a central hole 29'

[0047] The interior of the chamber 5 is then in communication with the pump 19 so that by activating the pump 19 to generate a flow from the interior 5 of the chamber to the collection tank 18, the gas produced by the arc discharge between the first electrode 20 and the second electrode 40 can be easily removed. The produced carbon black is collected in collection box 18. The outfl...

no. 3 example

[0052] A third embodiment of the invention is shown in FIG. 5 . Components that are the same as those illustrated and described in the first and second embodiments are assigned the same reference numerals, and therefore descriptions of these components are omitted here. In this example, however, the carbon nanostructures are constructed from carbon components introduced in the gaseous state. That is, this embodiment is a CVD (Chemical Vapor Deposition) process.

[0053] The chamber 1 of this embodiment has an inlet tube 16' and a chamber outlet 10; the chamber inlet 6 is not required, but could be included if desired. That is, the introduction pipe 16' is connected to the central through hole 29' of the first electrode 20 and supplies gas to the arc plasma region and the chamber interior 5. An equal amount of gas exits the chamber 1 through the chamber outlet 10 in order to keep the pressure inside the chamber interior 5 constant during the arc discharge.

[0054] The carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com