Continuous-surface shape mask moving photoetching exposure device

An exposure device and mask technology, which is applied in microlithography exposure equipment, photolithography exposure device, optics, etc., can solve the problem that the quality and production efficiency of continuous surface components cannot be greatly improved, the continuous surface shape of components is not smooth enough, Insufficient production function, production precision, operation and convenience, etc., to achieve the effect of continuous distribution of exposure dose, complete functions, and cheap equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

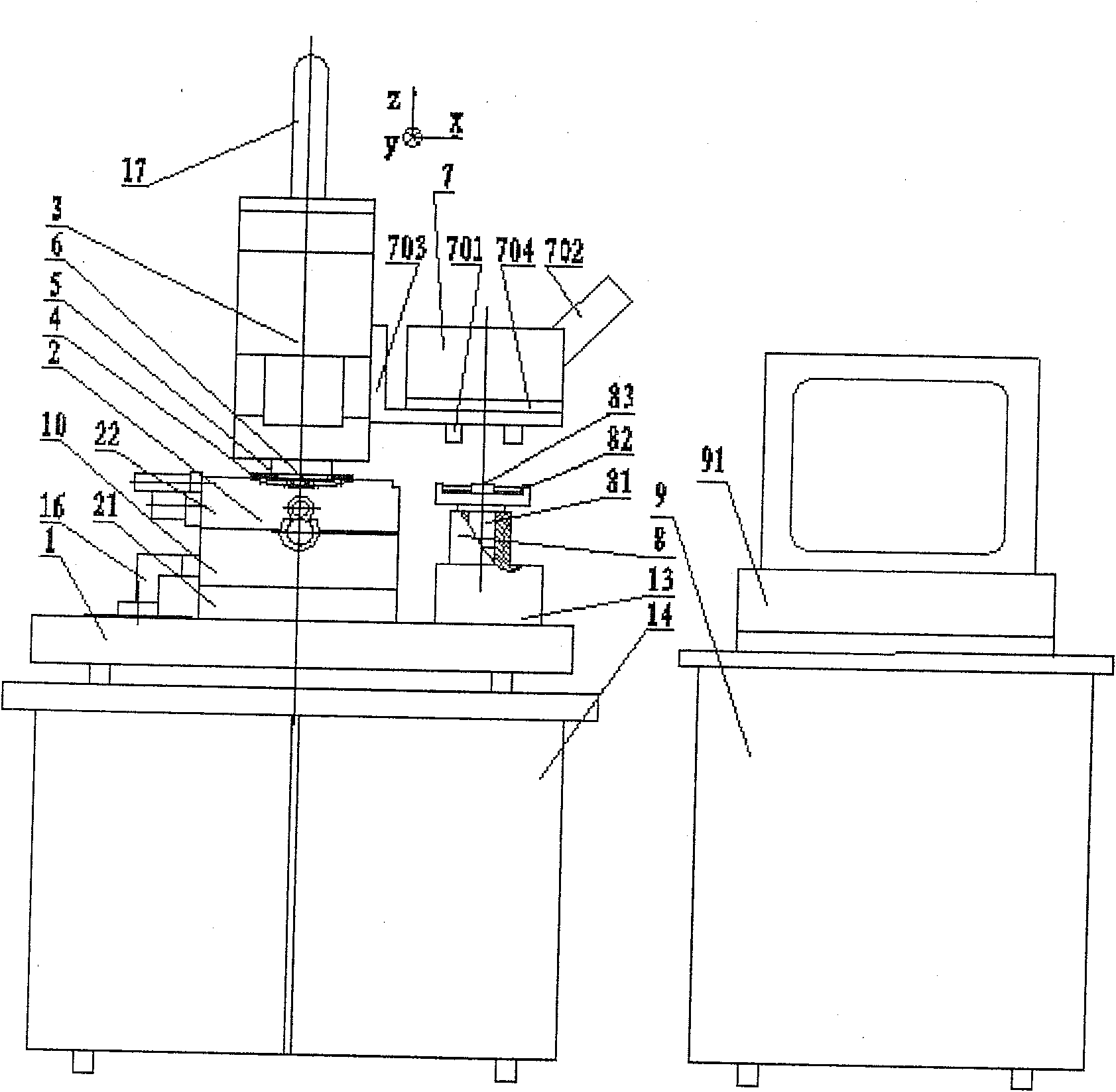

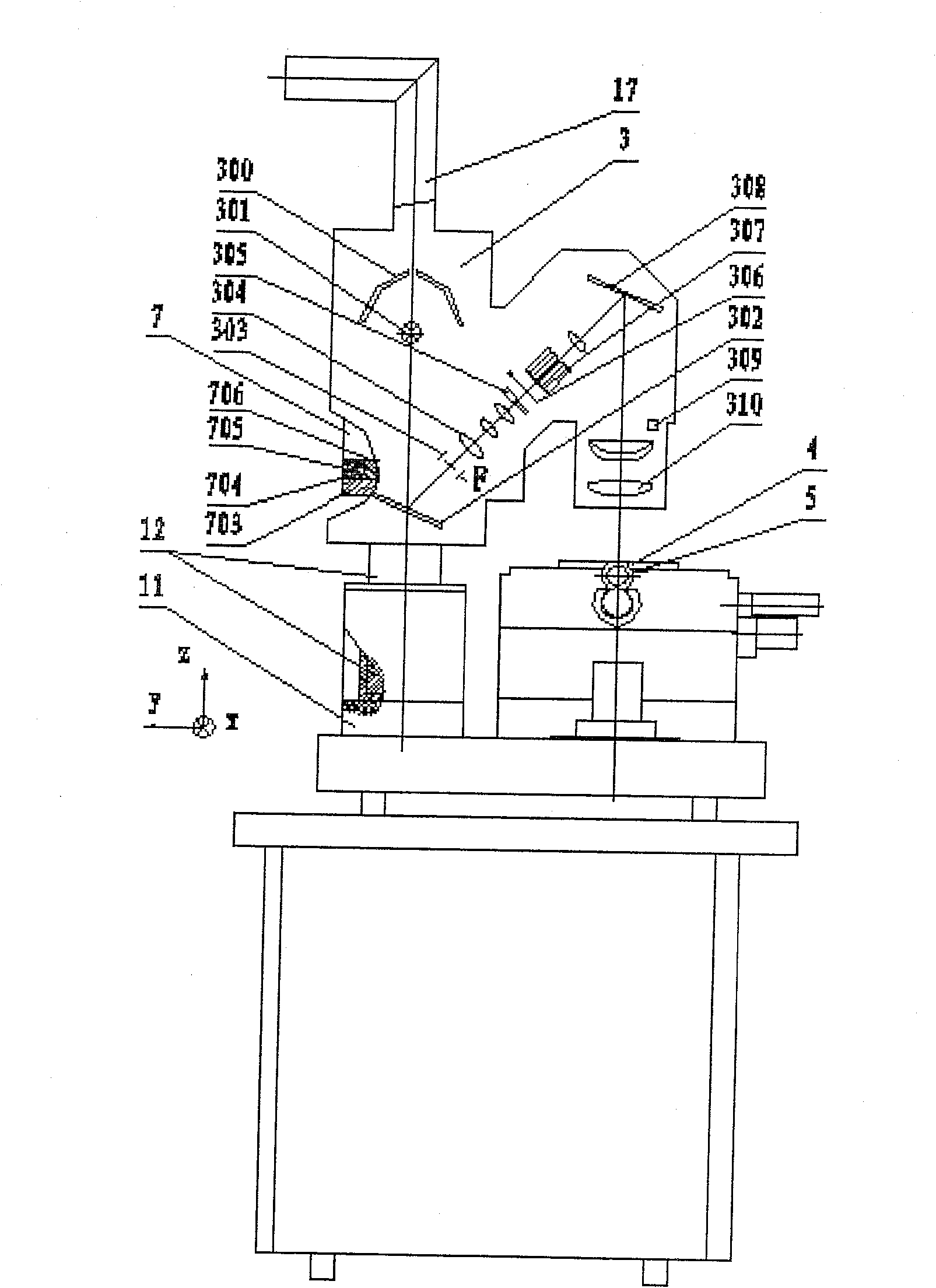

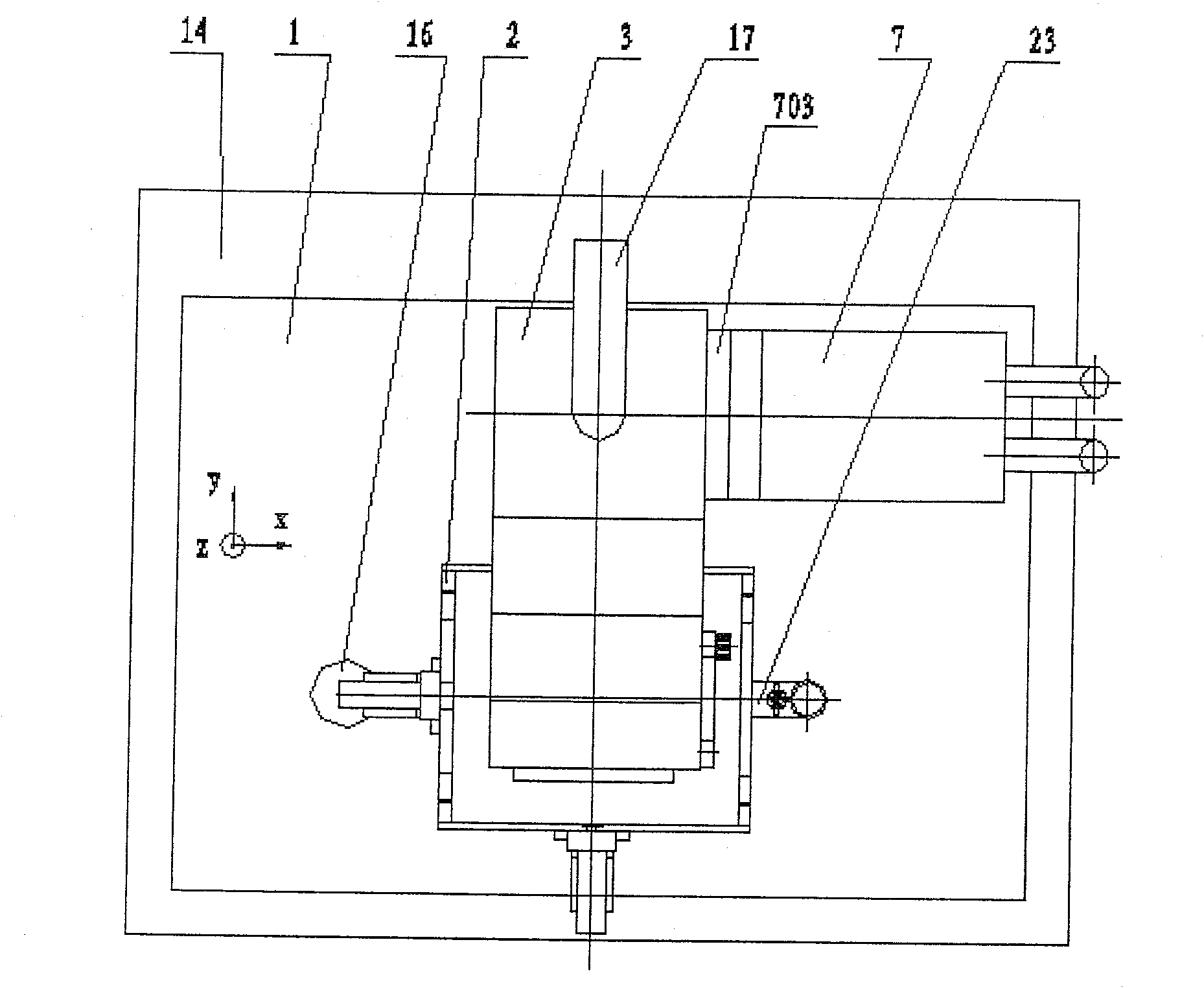

[0024] Such as figure 1 As shown, the present invention includes a host large substrate 1, a mask moving table system 2, a uniform illumination system 3, a mask frame 4, a mask 5, a substrate 6, an alignment observation system 7, an illumination uniformity detection system 8 and The control system 9 and the large base plate 1 of the main machine are placed on the vibration isolation platform 14 composed of air feet, so that the main machine of the present invention is not affected by the vibration of the external environment when performing the photolithography exposure of the moving mask. On the large substrate 1 of the host machine, a mask mobile workbench system 2 and an illumination uniformity detection system 8 are respectively fixed, wherein the illumination uniformity detection system 8 is connected to the large substrate 1 through a bracket 13, and the mask mobile workbench system 2 is located on the ground floor The XY manual table 21 and the XY mask moving table 22 c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com