HSK tool shank possessing capacity of compensation

A tool holder and capability technology, applied in the fields of precision, high-speed machining machine tools and HSK tool holders, can solve problems such as scrapping and performance degradation, and achieve the effect of reducing production costs, environmental requirements and reliable installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment is described in detail as follows:

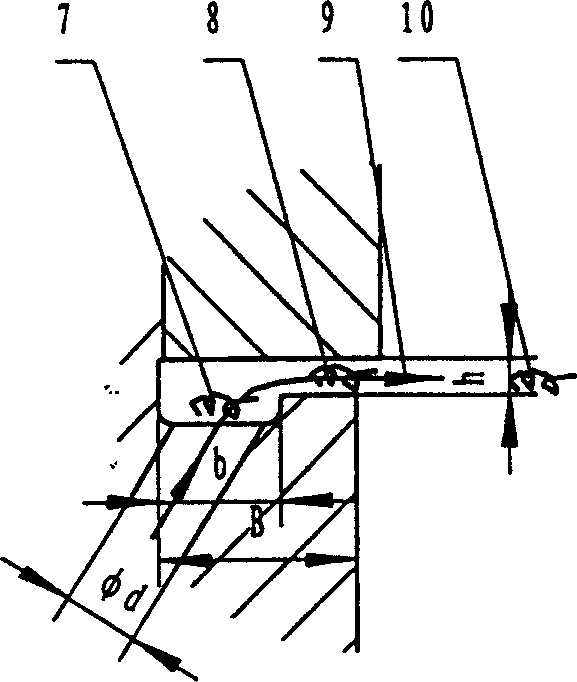

[0030] Such as figure 2 As shown, the relevant functional parameters of this embodiment are specifically as follows:

[0031] The width of the flange surface B = 7.5mm

[0032] Decontamination ring groove depth h=1mm

[0033] Decontamination ring groove width b=0.5×B=3.75mm

[0034] The diameter of the dedicated flushing channel d=3mm

[0035] The number of dedicated flushing channels is 4

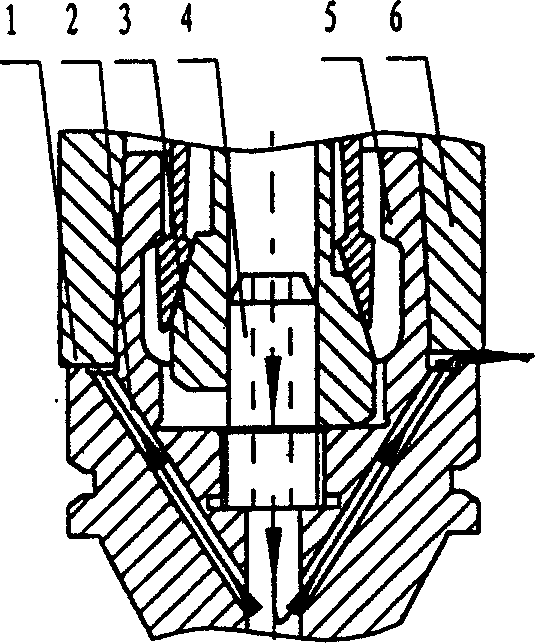

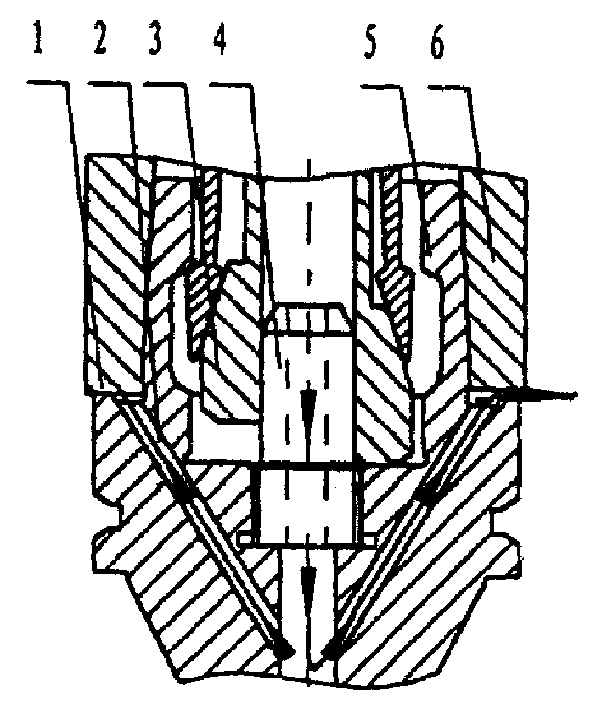

[0036] Its working process is as figure 1 Shown; the process of cleaning compensation is:

[0037] Before the HSK tool holder 5 is clamped, there is a gap between the flange surface 1 of the tool holder and the end surface of the machine tool spindle 6 . When there is dirt or chips 7 in the range of the decontamination ring groove, as long as its thickness is less than 1 mm of the depth of the decontamination ring groove, it will not affect the reliable contact between the flange surface 1 of the HSK tool holder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com