Polyacrylic acid film forming compsn.

A composition, polymer technology, applied in the production of this dosage form, non-gel-forming film-forming coating weight, increased water solubility on dip-coated tablets or caplets, capable of addressing gloss loss, surface roughness, encapsulation Clothes look unsatisfactory, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

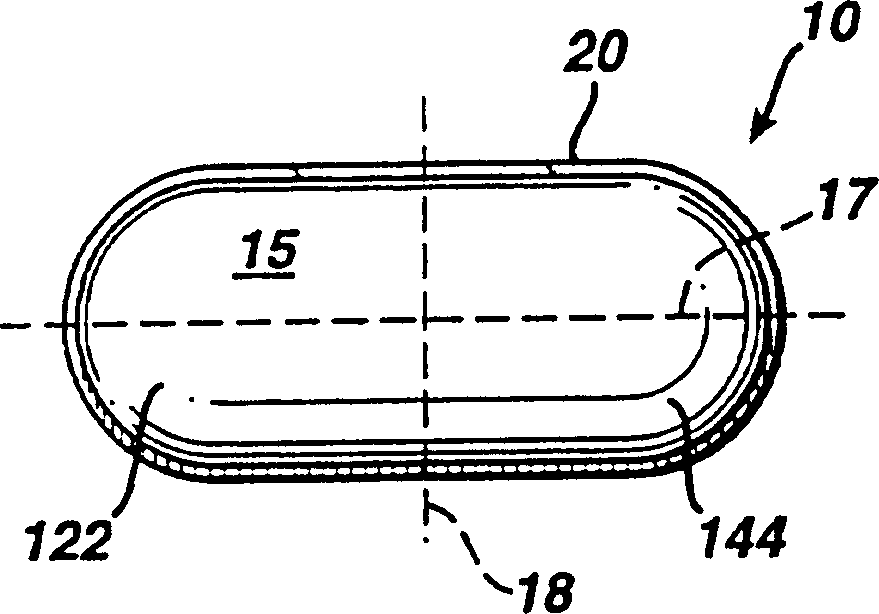

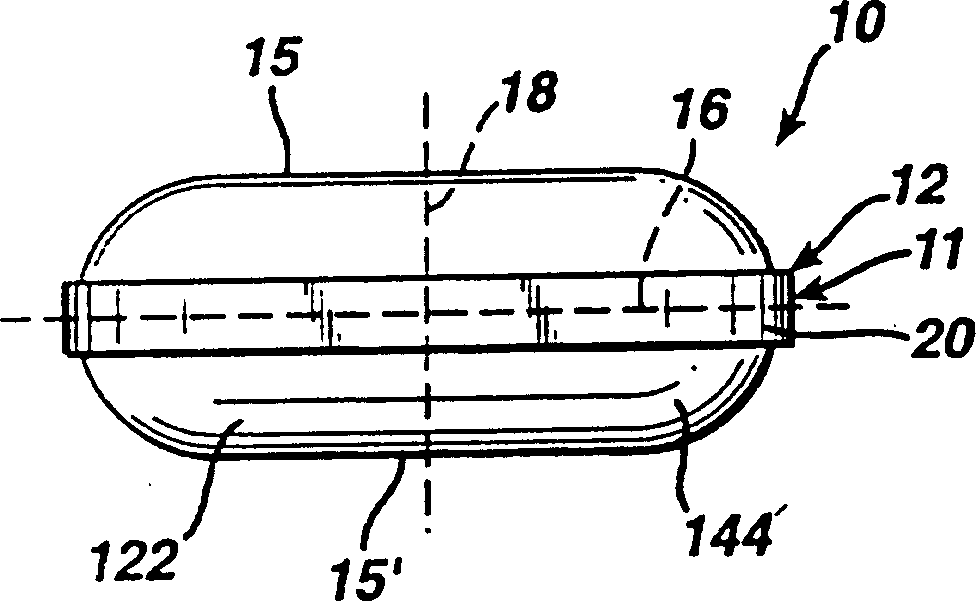

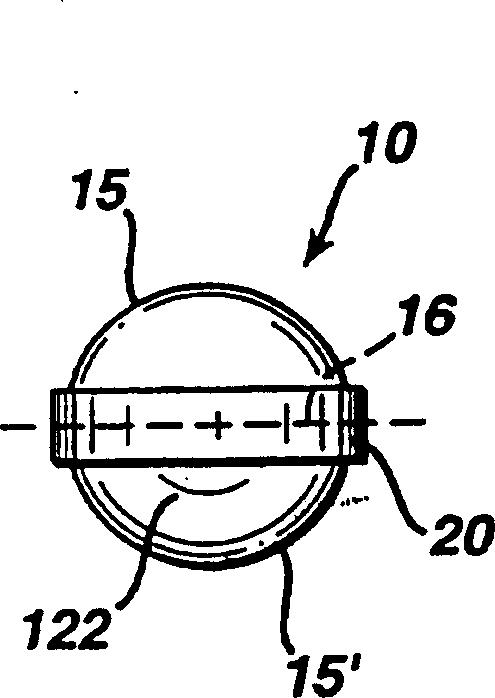

Image

Examples

Embodiment 1

[0072] Embodiment 1) prepare dip-coating dispersion liquid

[0073] Aqueous dispersions containing the ingredients listed in Table A were prepared.

[0074] Element

Weight (g)

Available from Rohm Pharma under the trade name "Eudragit RL30D"

Poly(ethyl acrylate, methyl methacrylate), methyl propylene chloride

Trimethylaminoethyl enoate (30% solution) *

100.0

5.0

Bought from BASF Aktiengesellschaft under the trade name "K-90"

12.0

water

60.0

Red#55 dye

1.0

Red#40 Lake

0.5

PEG400

4.0

total solution weight

182.5

solids in paint solution

52.5g(28.78%)

[0075] Element

Weight (g)

Available from Rohm Pharma under the trade name "Eudragit RL30D"

Poly(ethyl acrylate, methyl methacrylate), methyl propylene chloride

Trimethylaminoethyl enoate (30% solution) ...

Embodiment 2

[0078] Embodiment 2) preparation secondary coating dispersion liquid

[0079] An aqueous dispersion containing the ingredients listed in Table C was prepared by mixing all ingredients in a beaker under ambient conditions.

[0080] Element

Embodiment 3

[0081] Embodiment 3) prepare dip-coated tablet

[0082] Compressed tablets were prepared according to the method set forth in Example 1 of US Patent No. 5,658,589 ("the '589 patent"), which is incorporated herein by reference.

[0083] The subcoat dispersion of Example 2 was then applied to the above-mentioned tablets by spraying according to the procedure given in the examples of the '589 patent. The weight of the dry tablet with the subcoat was about 4.5% greater than the tablet without the subcoat, ie the amount of the subcoat was about 4.5% of the weight of the uncoated core.

[0084]Half of each of these subcoated tablets was manually dipped into the first dip coating dispersion of Example 1 for a dwell time of 1 second, removed from the dip coating solution, and reapplied under ambient conditions. dry. This process was repeated for each tablet; the other half of each coated tablet was dip-coated in the second dip-coating dispersion of Example 1. The weight gains of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com