Method and apparatus of semiconductor generating electricity and producing hydrogen using temperature difference and liquid natural gas providing cooling energy

A technology of liquefied natural gas and temperature difference power generation, applied in applications, home appliances, and other seating furniture, etc., can solve the problems of large power consumption, large cooling water consumption, and high cost of hydrogen production, and reduce power consumption costs and equipment costs , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Method and device for semiconductor thermoelectric power generation using LNG cold energy

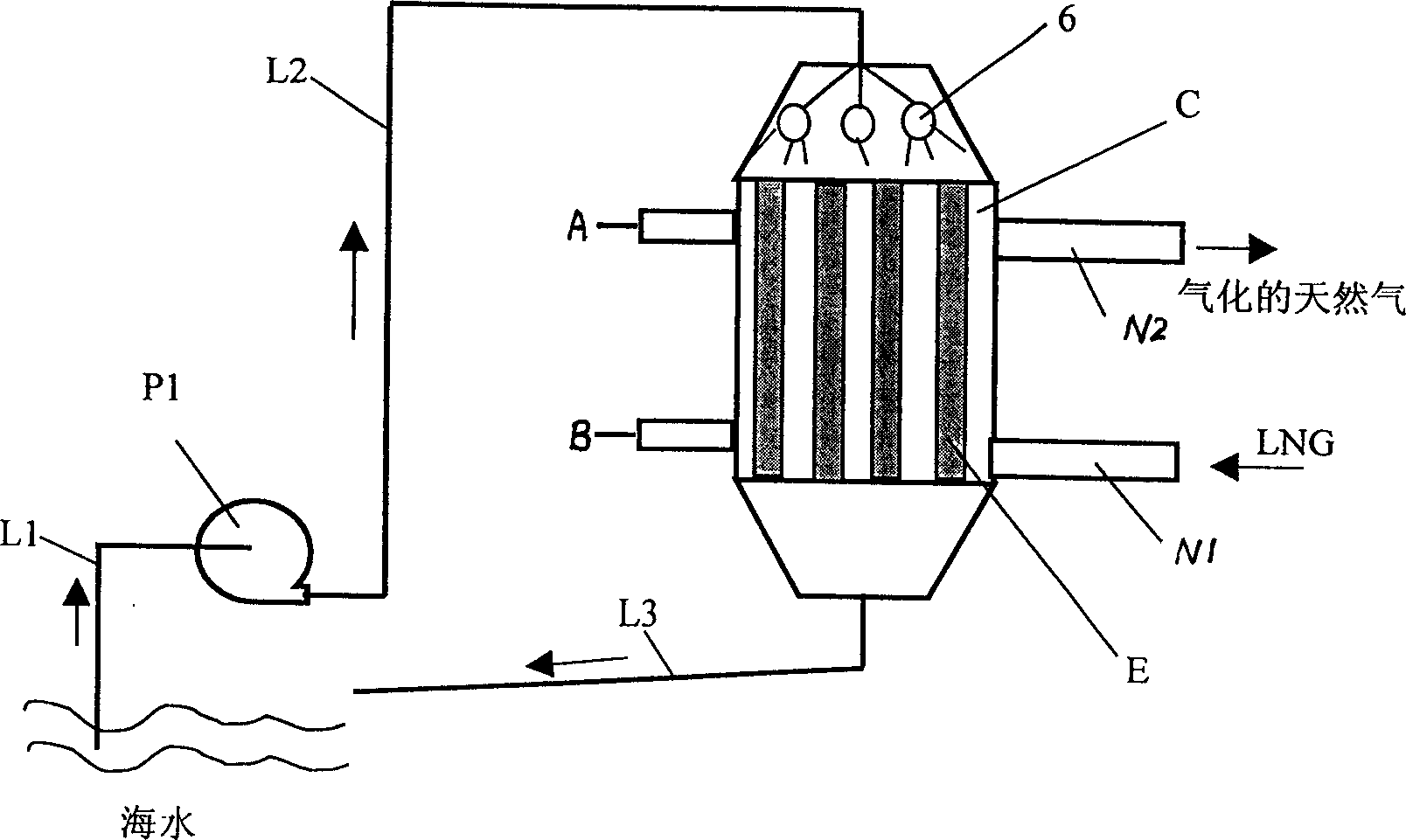

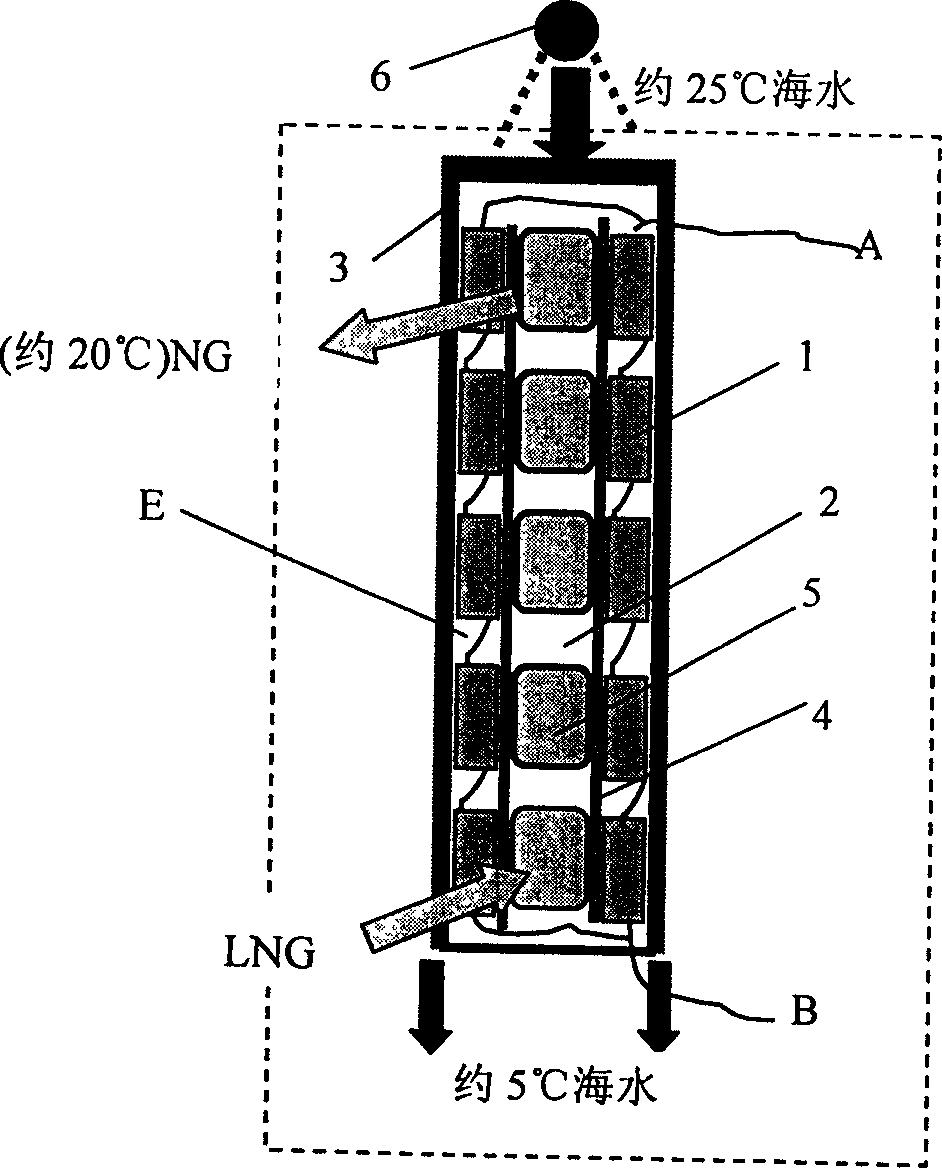

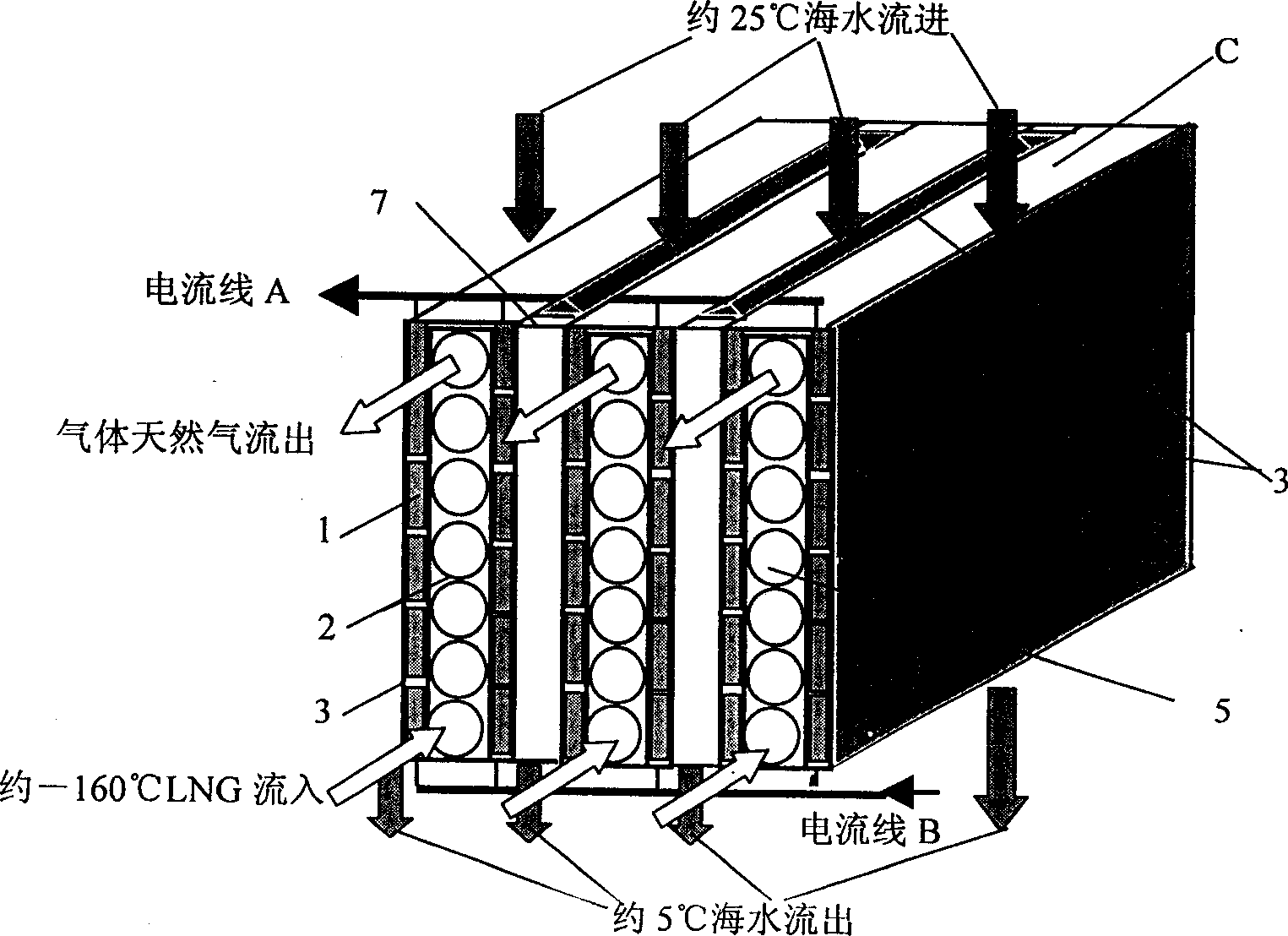

[0023] as attached figure 1 A schematic diagram of a device system flow chart of the method of semiconductor thermoelectric power generation using LNG cold energy is provided. The device system of this embodiment includes a semiconductor generator component C, a seawater pump P1, a seawater suction pipe L1, and a seawater delivery pipe L2 , seawater return pipe or channel L3, seawater spray pipe 6, LNG main inlet pipe N1 and gasification natural gas main outlet pipe N2, and current main incoming line A and main outgoing line B with protective tubes; the semiconductor generator assembly C consists of several The semiconductor generator unit E is combined. The structure of the semiconductor power generation unit E is as attached figure 2 As shown, the cold source heat exchanger adopts a plate-tube structure, and the metal plate 4 is made of an aluminum or copper plate...

Embodiment 2

[0026] Example 2: Using liquefied natural gas cold energy semiconductor temperature difference to generate hydrogen

[0027] Figure 4 It is a schematic diagram of the principle of a specific implementation of a hydrogen production device using LNG cold energy semiconductor thermoelectric power generation. It includes a semiconductor thermoelectric generator assembly and an electrolyzed water hydrogen production device. The semiconductor thermoelectric generator assembly in this embodiment is divided into two groups according to the temperature of the cold and heat sources: one group BD1 is drenched with normal seawater, and the other group BD2 is drenched with high temperature seawater that recovers waste heat from hydrogen production. In the electrolyzed water hydrogen production device H, the hydrogen side of the electrolytic cell D is sequentially connected to the hydrogen-gas-liquid separator F1 and the hydrogen-cooled water vapor condenser Y1; the oxygen side of the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com