Method of adding additive into absorbing lithium bromide refrigerator

An absorption refrigerator and additive technology, which is applied to refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of difficult recycling of additives, difficulty in adding additives into the absorber, and difficult control of the adding process, and the method is simple, The effect of easy addition process, large economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

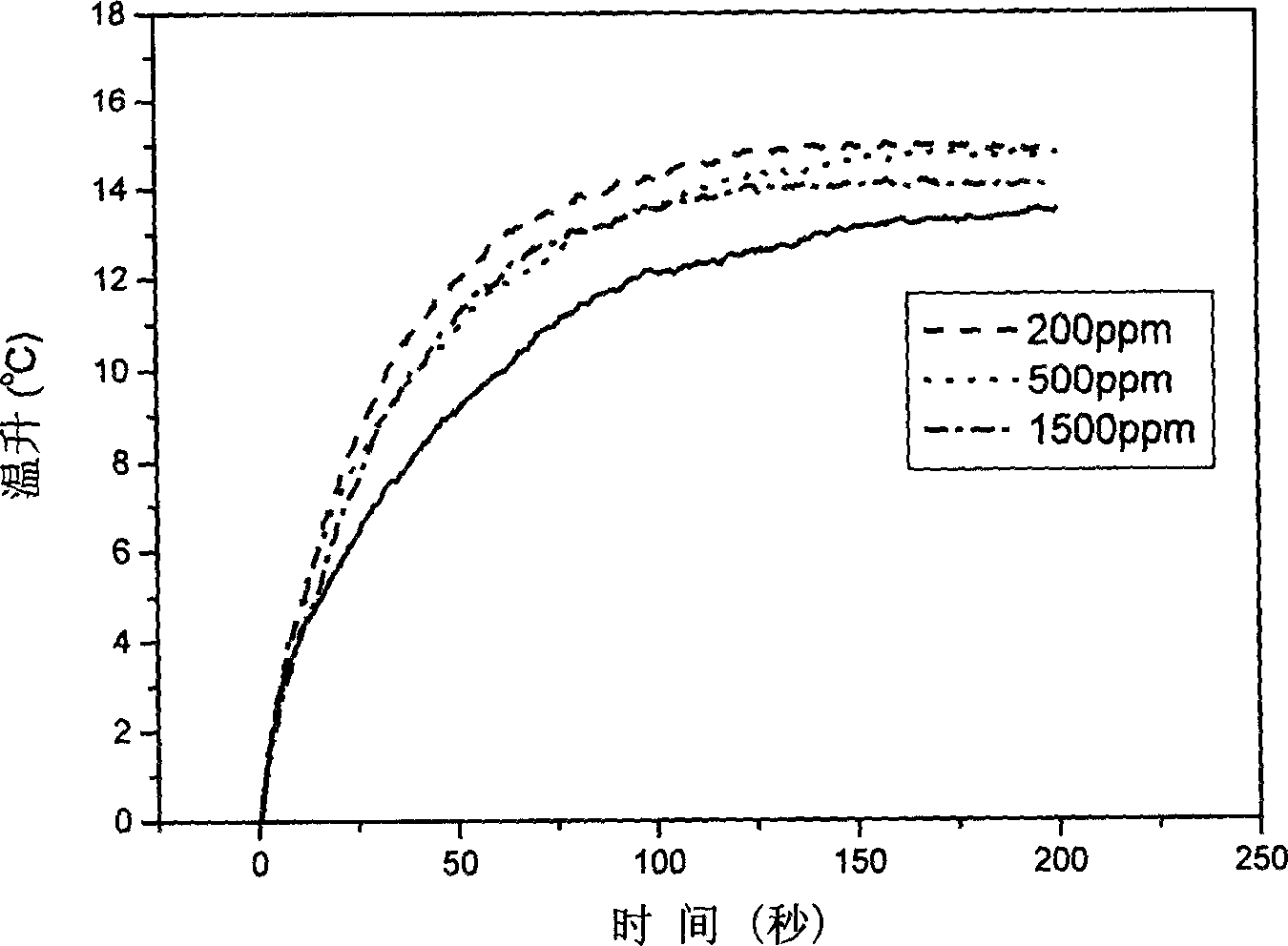

[0016] Embodiment 1. Add additive 2-ethyl hexanol to the single-effect absorption refrigerator to strengthen lithium bromide solution to absorb water vapor.

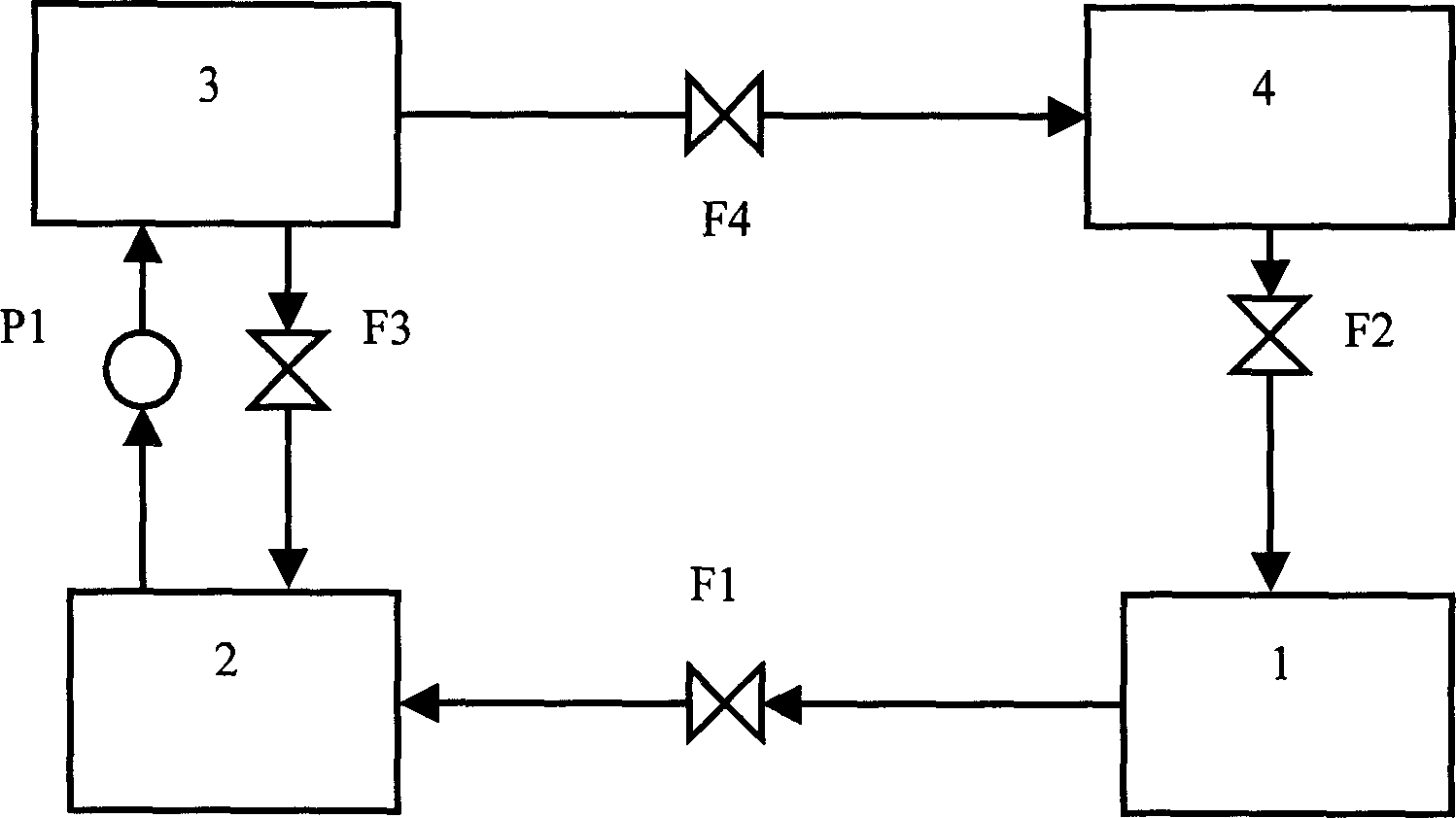

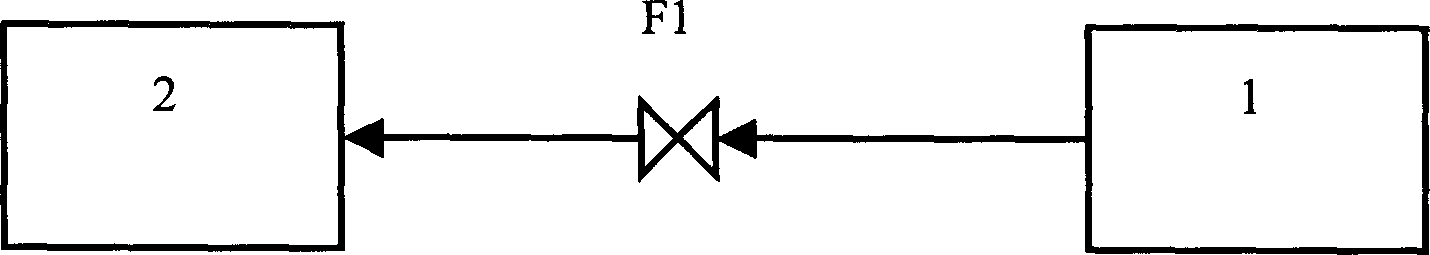

[0017] Adopt single-effect lithium bromide absorption refrigerator, 3000 grams of water as refrigerant are housed in evaporator 1, and lithium bromide solution (being the lithium bromide aqueous solution of concentration 53.9%) as absorbent is housed in absorber 2. Take 0.6g, 1.5g, 4.5g of additive 2-ethylhexanol directly into the water of the evaporator through the refrigerant inlet, so that the concentration of the additive in the water is 200ppm, 500ppm, 1500ppm respectively; the whole system is in a vacuum state . During operation, the evaporator 1 communicates with the condenser 4 through the pipeline and the throttle valve F2, and the water evaporated in the evaporator 1 is replenished by the water in the condenser 4. The absorber 2 communicates with the generator 3 through the pipeline, the throttle valve F3, and...

Embodiment 2

[0018] Embodiment 2. Add additive 1-octanol to the single-effect absorption refrigerator to strengthen lithium bromide solution to absorb water vapor.

[0019]Adopt single-effect lithium bromide absorption refrigerator, 2500 grams of water as refrigerant are housed in evaporator 1, and lithium bromide solution (being the lithium bromide aqueous solution of concentration 53.9%) as absorbent is housed in absorber 2. Take 0.5 g, 1.25 g, 3.75 g, 7.5 g, and 25 g of additive 1-octanol directly into the water of the evaporator through the refrigerant inlet, so that the concentration of the additive in the water is 200 ppm, 500 ppm, 1500 ppm, 3000ppm, 10000ppm; the whole system is in a vacuum state. During operation, the evaporator 1 communicates with the condenser 4 through the pipeline and the throttle valve F2, and the water evaporated in the evaporator 1 is replenished by the water in the condenser 4. The absorber 2 communicates with the generator 3 through the pipeline, the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com