Mercury-containing gas discharge tube and suction device thereof

A technology of gas discharge tube and air suction device, which is applied to gas discharge lamps, discharge tubes, parts of gas discharge lamps, etc., can solve problems such as affecting the service life of mercury-containing gas discharge tubes, and achieve improved surface brightness and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

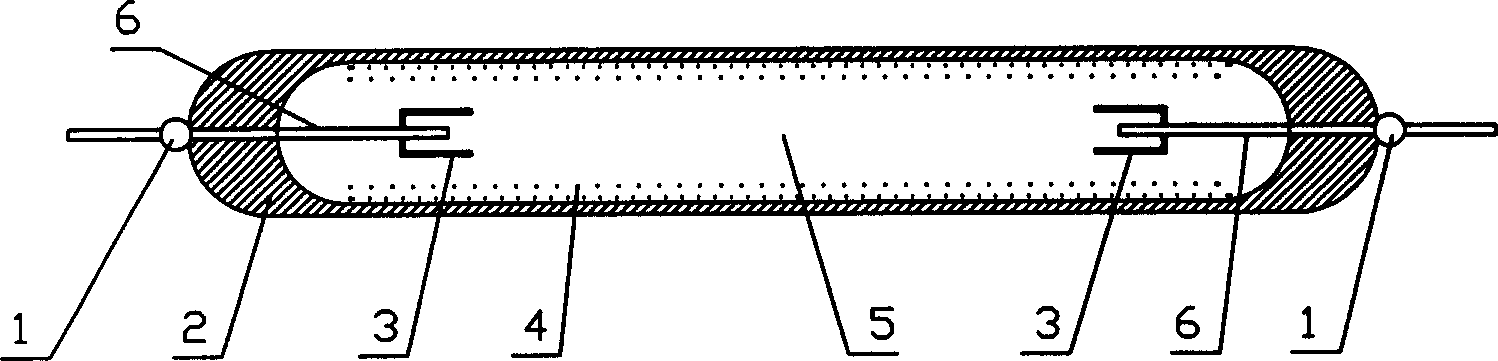

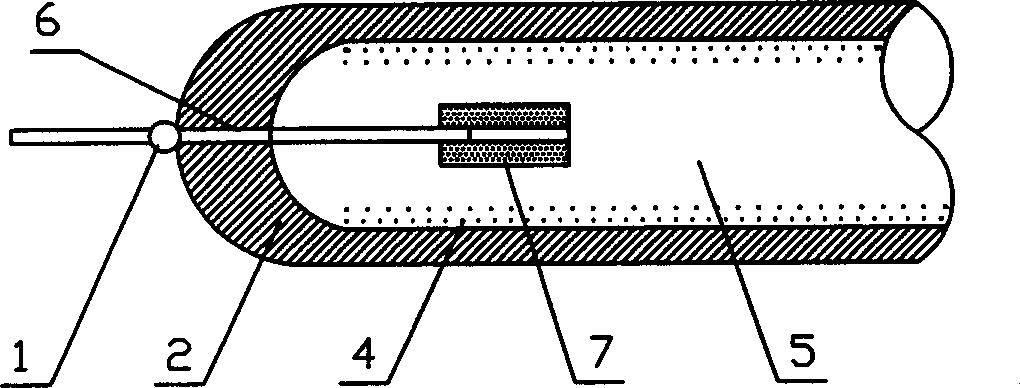

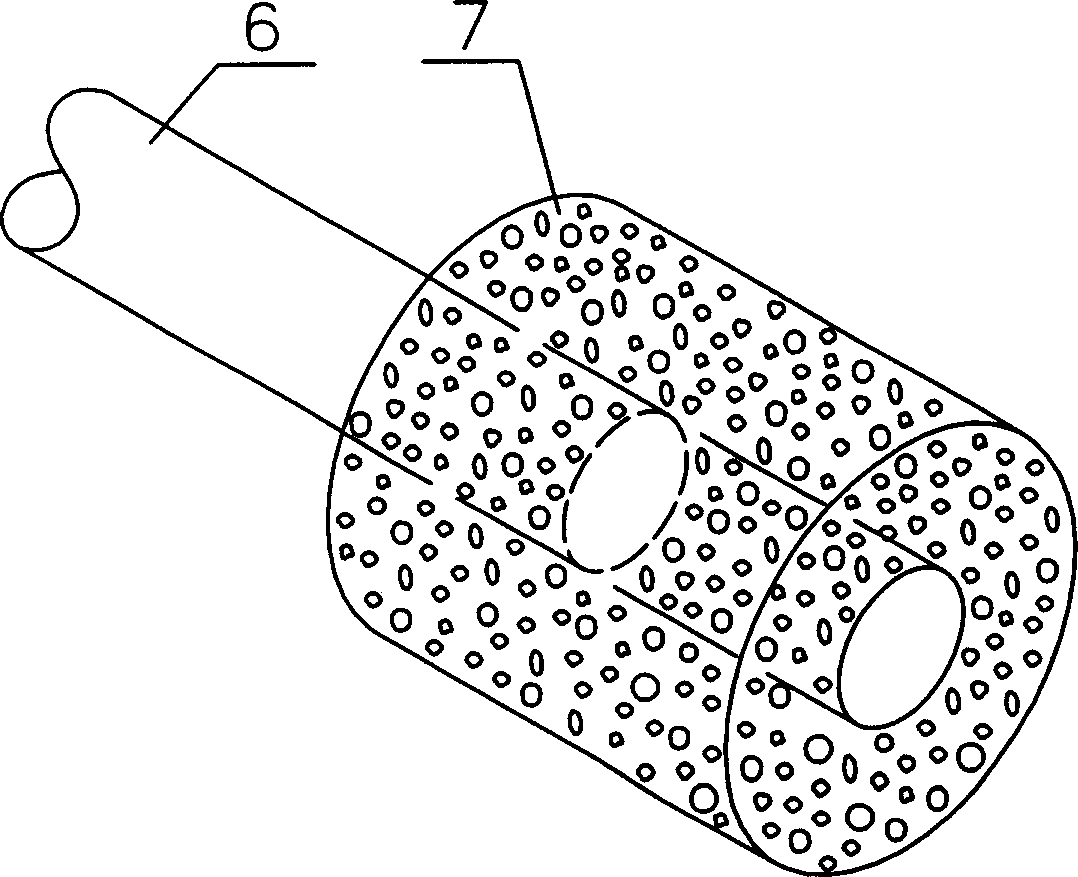

[0052] Straight tube cold cathode fluorescent lamp, the outer diameter of the lamp tube is 2.6 mm, the inner diameter of the lamp tube is 2.0 mm, and the length of the lamp tube is 243 mm. It uses a tungsten, molybdenum, iron, cobalt alloy tube welded on the tungsten wire as a suction device (at the same time as an electrode The role of), alloy cylinder composition range: tungsten + molybdenum (10% ~ 40%), iron + cobalt (60% ~ 90%). The suction device is sealed on the borosilicate glass (hard glass) tube. The inner wall of the glass tube is coated with fluorescent powder with a color temperature of 5800°K, and filled with an appropriate amount of neon-argon mixed gas and mercury vapor. The lamp tube uses a special lighting device. circuit. At the beginning of lighting, the lamp is lit at a working current of 7.5 mA, and the surface brightness of the lamp tube reaches 44000cd / m 2 , the luminous flux reaches 176Lm; the surface brightness of the lamp tube reaches 55000cd / m when ...

example 2

[0054] Straight-tube cold-cathode fluorescent lamp, the outer diameter of the lamp tube is 1.8 mm, the inner diameter of the lamp tube is 1.2 mm, and the length of the lamp tube is 72.5 mm. It uses a tungsten, molybdenum, iron, nickel, cobalt alloy tube welded on the tungsten wire as a suction device (at the same time The role of the electrode), the composition range of the alloy cylinder: tungsten + molybdenum (10% ~ 40%), iron + nickel + cobalt (60% ~ 90%). The suction device is sealed on the borosilicate glass (hard glass) tube. The inner wall of the glass tube is coated with fluorescent powder with a color temperature of 6500°K, and filled with an appropriate amount of neon-argon mixed gas and mercury vapor. The lamp tube uses a special lighting device. circuit. When starting to light the lamp, light it at a working current of 2 mA (normally produced lamps cannot be lit at a working current of 2 mA for a long time), and the surface brightness of the lamp reaches 28930cd / m ...

example 3

[0056] Straight-tube cold-cathode fluorescent lamp, the outer diameter of the lamp tube is 2.6 mm, the inner diameter of the lamp tube is 2.0 mm, and the length of the lamp tube is 243 mm. It uses a tungsten, molybdenum, iron, and cobalt alloy tube welded on the tungsten wire as a suction device (at the same time, the electrode role), alloy cylinder composition range: tungsten + molybdenum (70% ~ 90%), iron + cobalt (10% ~ 30%). The suction device is sealed on the borosilicate glass (hard glass) tube. The inner wall of the glass tube is coated with fluorescent powder with a color temperature of 5800°K, and filled with an appropriate amount of neon-argon mixed gas and mercury vapor. The lamp tube uses a special lighting device. circuit. At the beginning of lighting, the surface brightness of the lamp reaches 44000cd / m under the working current of 7.5mA 2 . After the lamp has been subjected to a life test equivalent to 15,000 hours of normal lighting at an aging current of 15 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com