Method for preparing 1-ethene under ethene oligomerizating catalyst system

A technology for ethylene oligomerization and catalysts, applied in chemical instruments and methods, organic chemistry, hydrocarbons, etc., can solve problems such as uneven mass and heat transfer, high local temperature, and the influence of complex catalysts on the catalytic effect, and achieve Good heat transfer effect and uniform mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

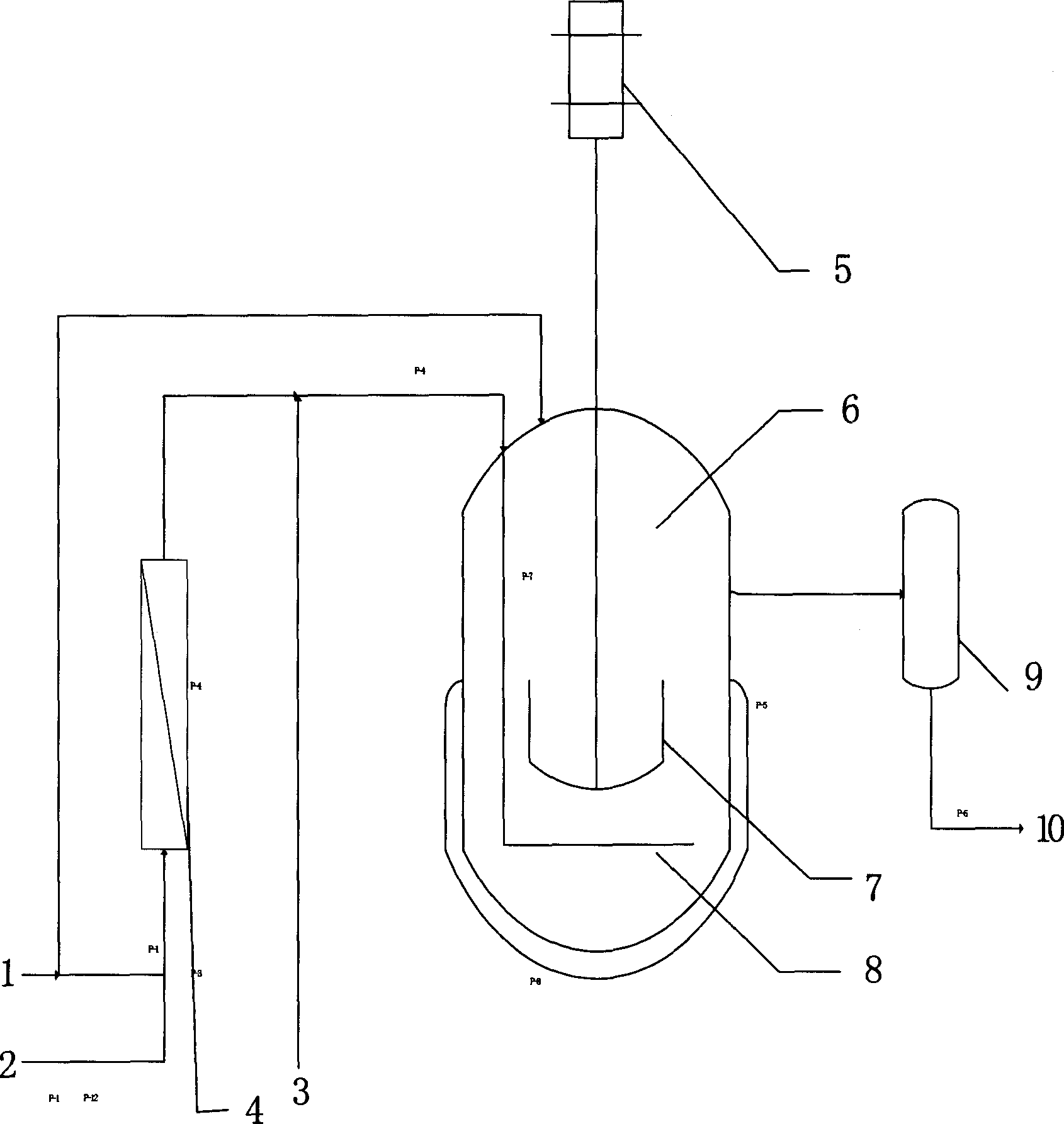

[0030] In the reactor (6) with the agitator (7) driven by the motor (5), a distributor (8) of stainless steel pipes with evenly distributed apertures is installed on the wall below the agitator. The ratio of the small hole diameter of the distributor to the diameter of the stainless steel pipe is 50%. The distributor is connected to the premixer (4). The premixer is composed of two stainless steel pipes. filler. The feed port of the premixer is connected with the solvent (2) and the raw material ethylene (1) tank, and the raw material ethylene (1) tank is directly connected with the top of the reactor, and the overflow tank (9) connected with the separation device (10) is connected with the reaction tank. The discharge port in the middle of the device is connected, and the catalyst inlet (3) is arranged between the distributor and the premixer.

[0031] After the assembled reactor was cleaned with cyclohexane, it was vacuum-dried at 100°C for 1 hour, cooled to room temperatur...

Embodiment 2-7

[0033] The process conditions and results are shown in Table 1.

[0034] Reality

[0035] Catalyst a

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com