Magnetic RAM, its mfg. and driving method

A technology of random access memory and magnetic tunnel junction, which is applied in static memory, digital memory information, semiconductor/solid state device manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

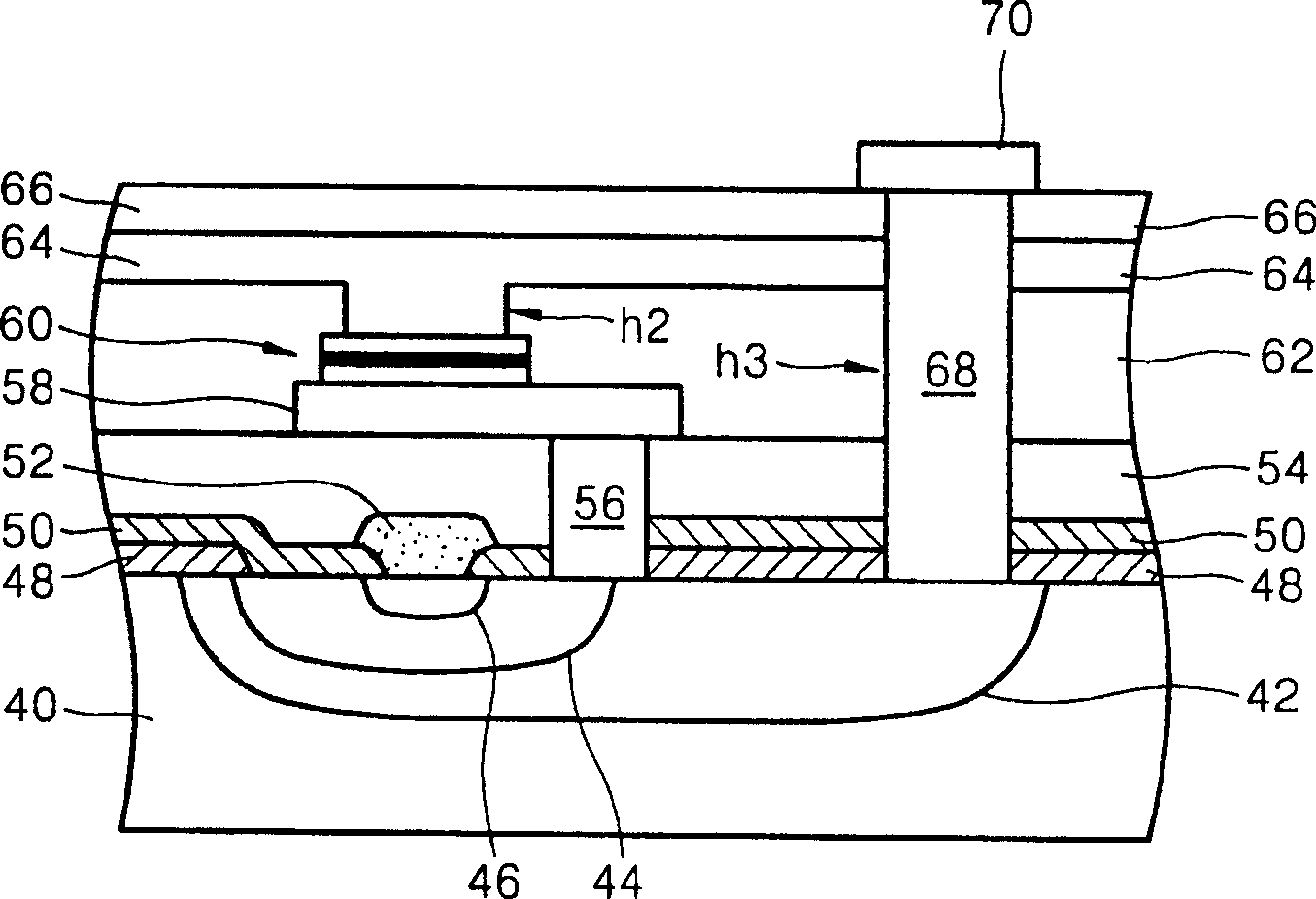

[0027] An MRAM according to an embodiment of the present invention and methods of manufacturing and driving the same will be described in detail with reference to the accompanying drawings. In the drawings, the shapes of elements are exaggerated for clarity.

[0028] First, the MRAM according to the present invention will be explained.

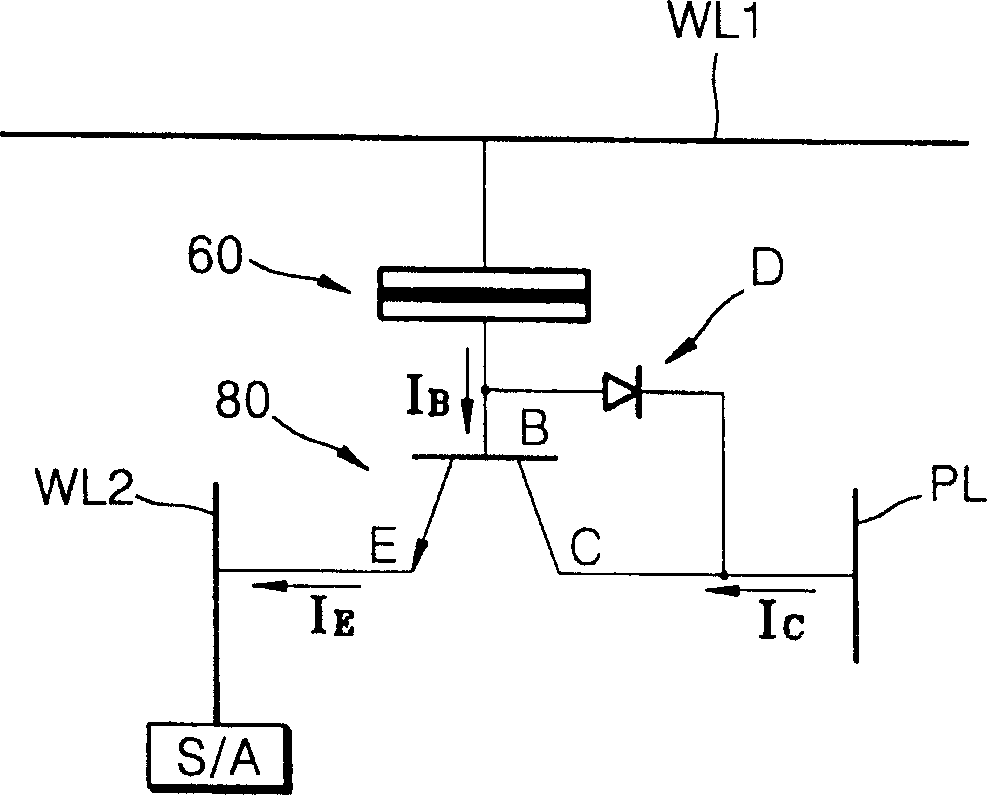

[0029] see figure 1 , the n-type first impurity region 42 is formed by doping a first conductive impurity such as phosphorus (P) in the semiconductor substrate 40 to a predetermined depth. The n-type first impurity region 42 functions as a collector of a bipolar junction transistor (BJT). The p-type impurity region 44 is formed by doping second conductive impurities such as boron (B) in the n-type first impurity region 42 . The p-type impurity region 44 serves as the base of the BJT. no + The p-type second impurity region 46 is formed by doping the p-type impurity region 44 with third conductive impurities. no + Type second impurity reg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com