Magnetooptic recording medium and reproducing method therefor

A recording medium, opto-magnetic technology, applied in the direction of magnetic recording, combined recording, data recording, etc., can solve the problems of small reproduced signal, limited length, unable to prevent overlapping signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

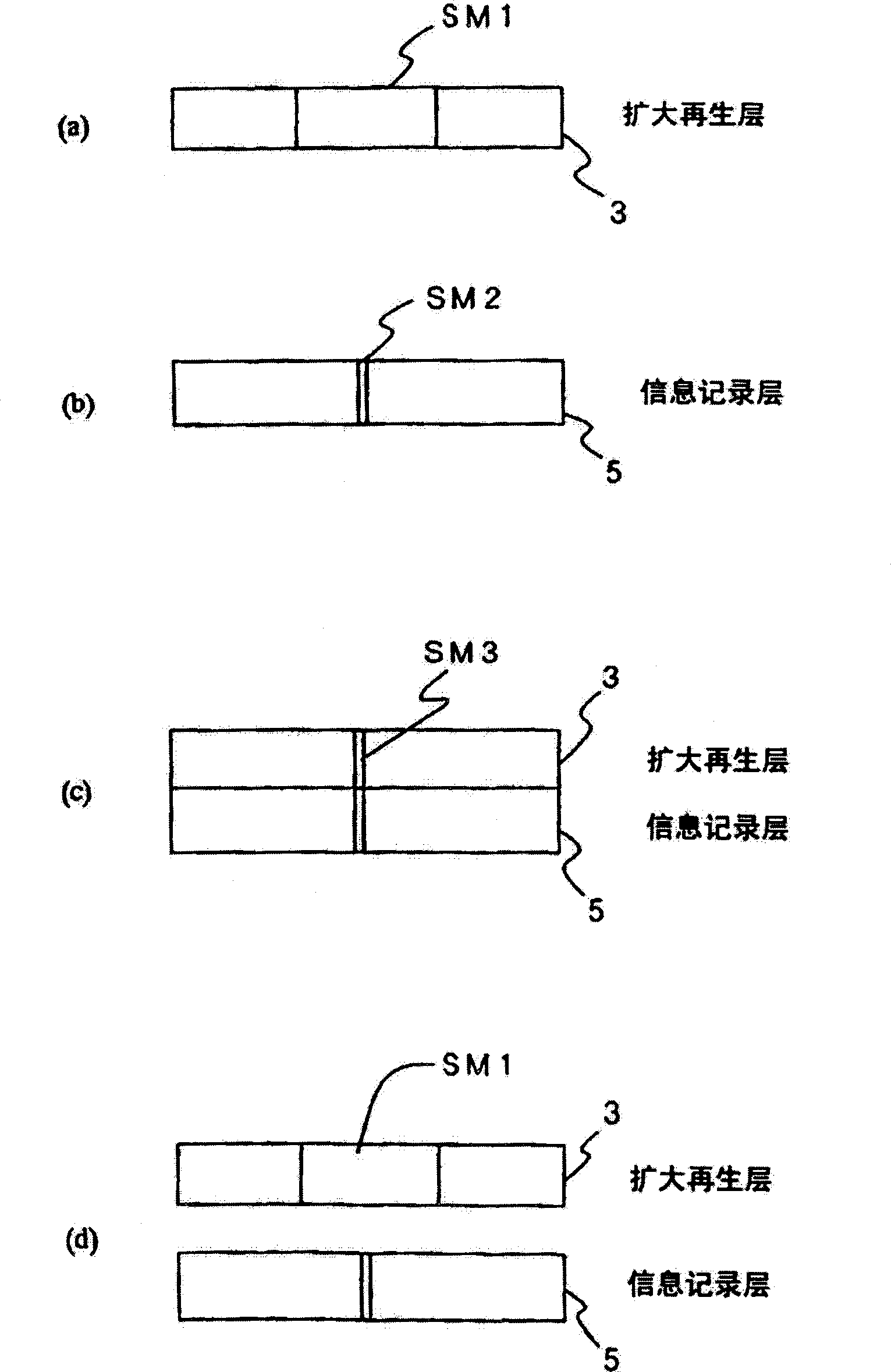

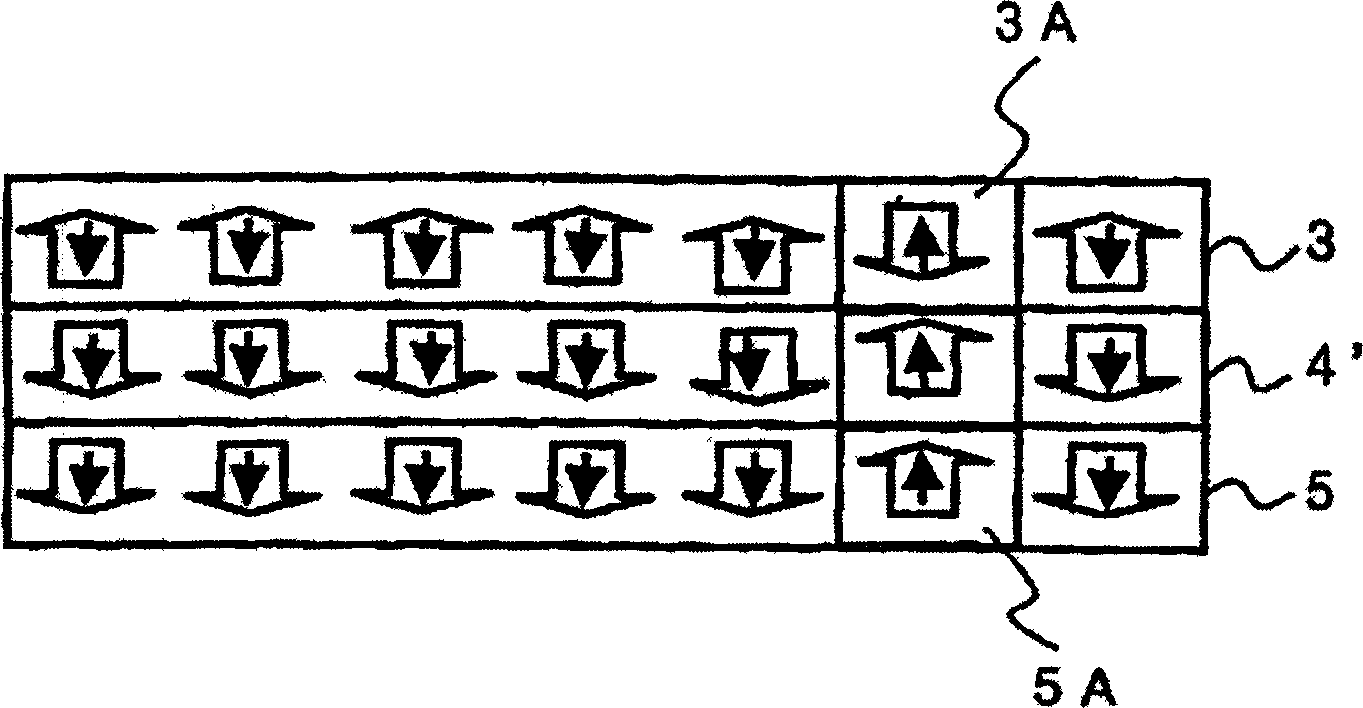

[0129] This example is made as Figure 20 A magneto-optical disk 300 of the structure shown. The magneto-optical disk 300 corresponds to the first type of magneto-optical recording medium of the present invention. The magneto-optical disk 300 is provided with a dielectric layer 2, an expansion reproduction layer (magnetic domain expansion reproduction layer) 3, an expansion activation layer 4′, a recording layer 5, a protective layer 7, a heat dissipation layer 8 and a protective coating 9 on a substrate 1. Such a magneto-optical recording medium 300 was manufactured using a high-frequency sputtering apparatus as follows.

[0130] Substrate 1 is used as Figure 21 Polycarbonate substrates of the shape shown. The substrate 1 has a track pitch TP=700nm, a land half-width value L=200nm, a groove half-width value G=500nm, a groove depth D=60nm and a thickness of 0.6mm. The land half-width value L and the groove half-width value G respectively represent the widths of the land a...

Embodiment 2

[0139] A plurality of magneto-optical disk samples were produced in the same manner as in Example 1 except that the enlarged reproduction layer 3 of the magneto-optical disk was changed to various thicknesses of 10 to 15 nm. Bit error rate (BER) measurement was performed on these magneto-optical disks as in Example 1. The relationship between the various film thicknesses t of the enlarged reproduction layer 3 and the measured bit error rate is as follows: Figure 31 shown. Depend on Figure 31 It can be seen that when the film thickness t of the enlarged reproduction layer 3 is in the range of 15-30 nm, the error rate is 1×10 -4 . This is because if the thickness of the enlarged reproduction layer 3 is thinner than the above range, the recording magnetic domains of the enlarged trigger layer and the recording layer will be seen through the reproduction layer, making accurate signal reproduction difficult. On the other hand, when the film thickness of the expanded reproduct...

Embodiment 3

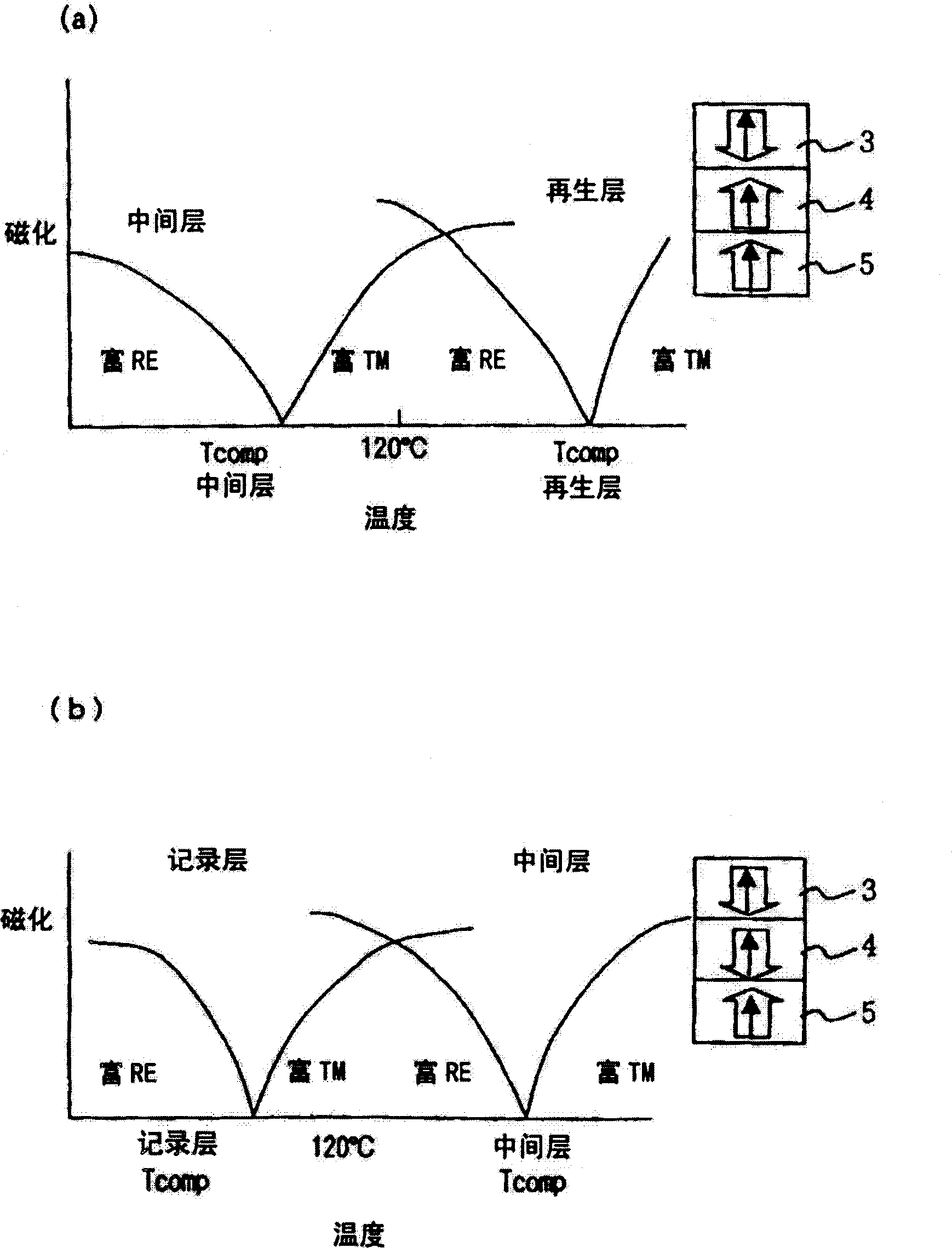

[0141] This example is about the method of obtaining the magnitude of the exchange coupling magnetic field (exchange coupling force) acting between the enlarged reproduction layer and the recording layer of the magneto-optical disk produced in Example 1. The exchange bonding force can be obtained by measuring the magnetic field dependence of the magneto-optical Kerr effect from the enlarged reproduction layer side. Figure 25 Shown is the hysteresis curve of the magneto-optical disk of Example 1 at room temperature. This hysteresis curve is obtained by injecting measurement light from the enlarged reproduction layer side and measuring the magnetic field dependence of the polar magneto-optical Kerr rotation angle. On the enlarged reproduction layer, the information recording layer with a large coercive force acts to exchange the combined magnetic field, and the hysteresis curve is shifted to the left side (negative magnetic field side). This offset corresponds to the exchange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com