Surface acoustic wave device and wave filter employing the same

A surface acoustic wave device and surface acoustic wave technology, applied in electrical components, impedance networks, etc., can solve the problems of frequency deviation, affecting the performance of SAW devices, and frequency deviation of SAW devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described below with reference to the drawings.

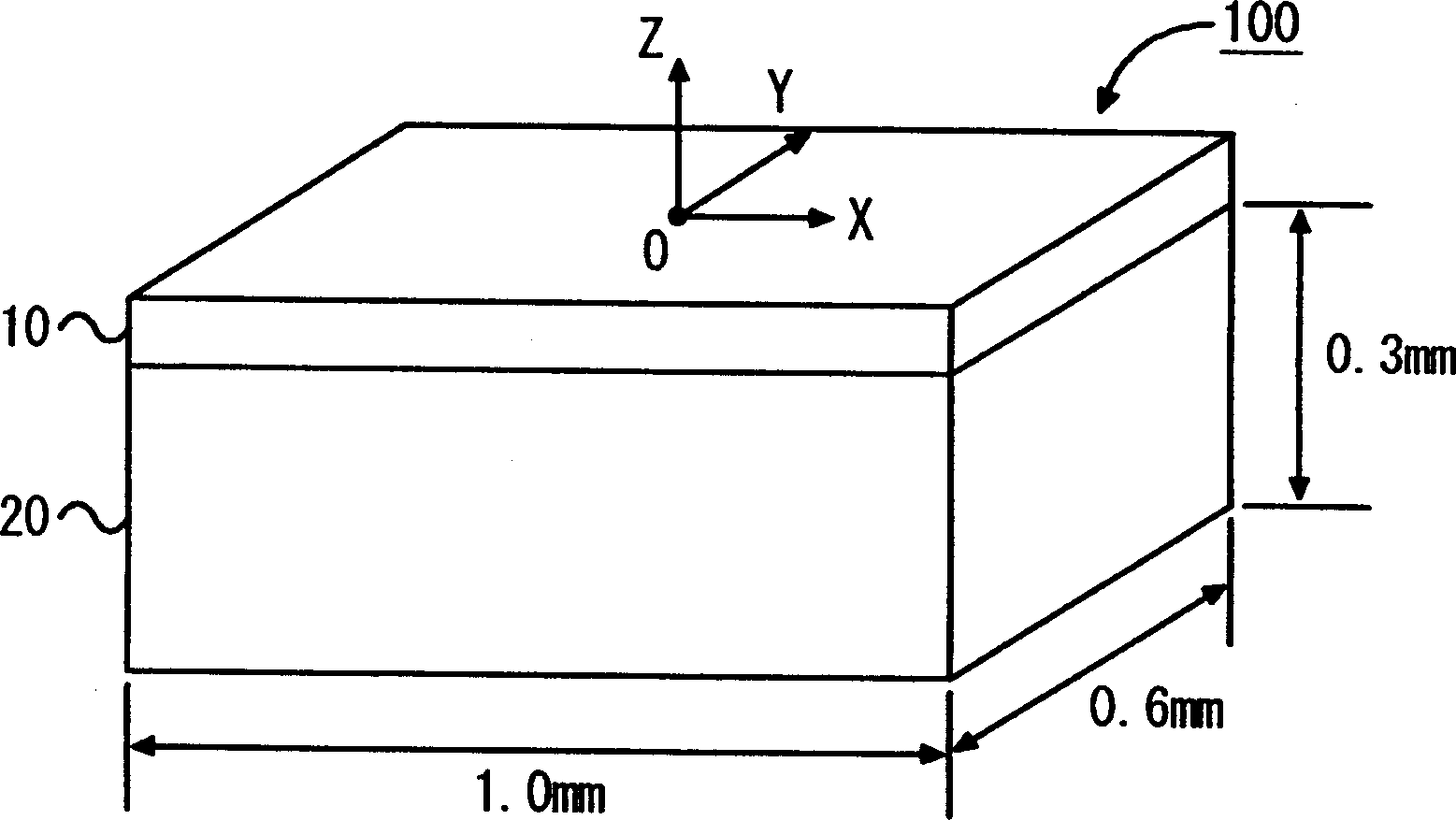

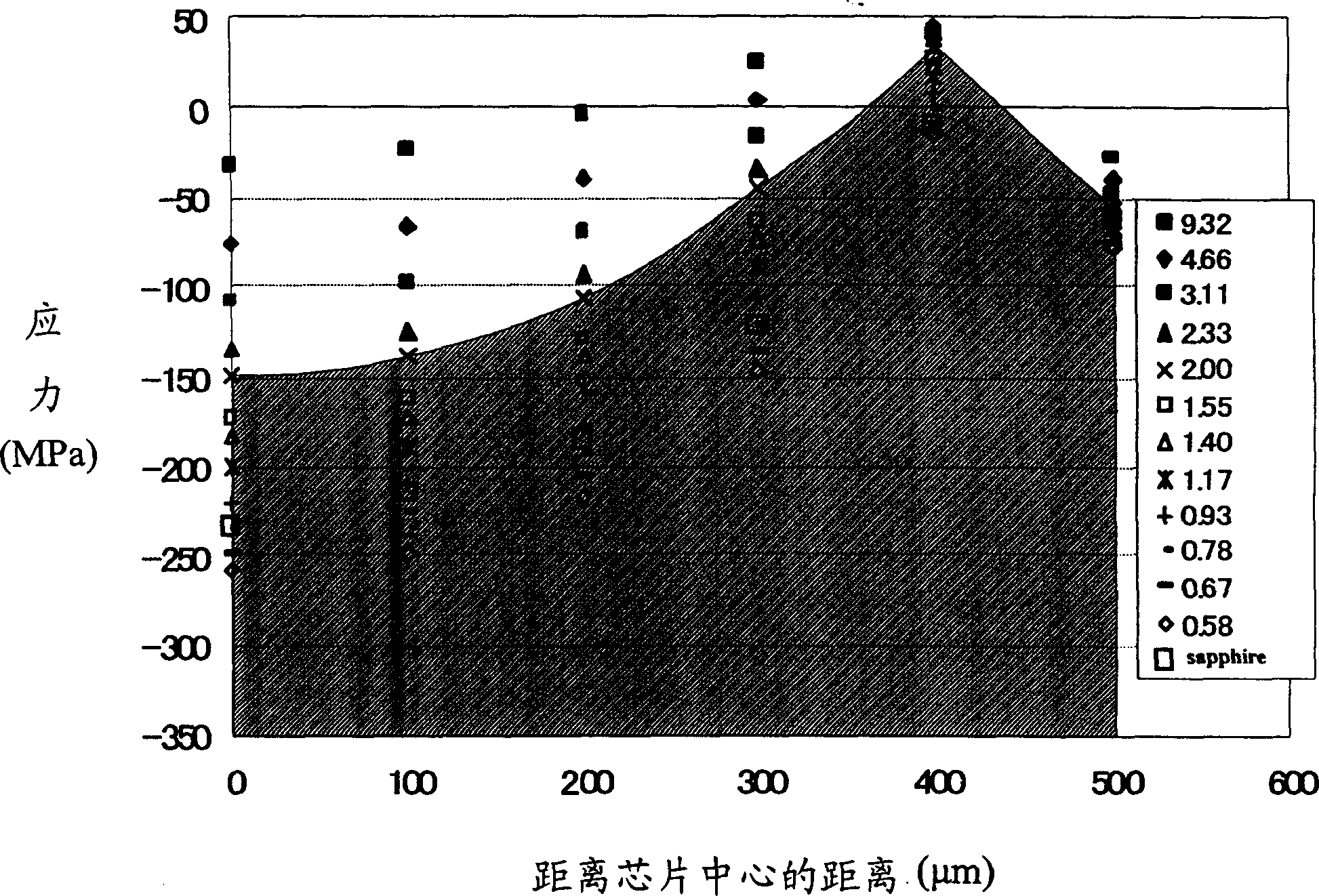

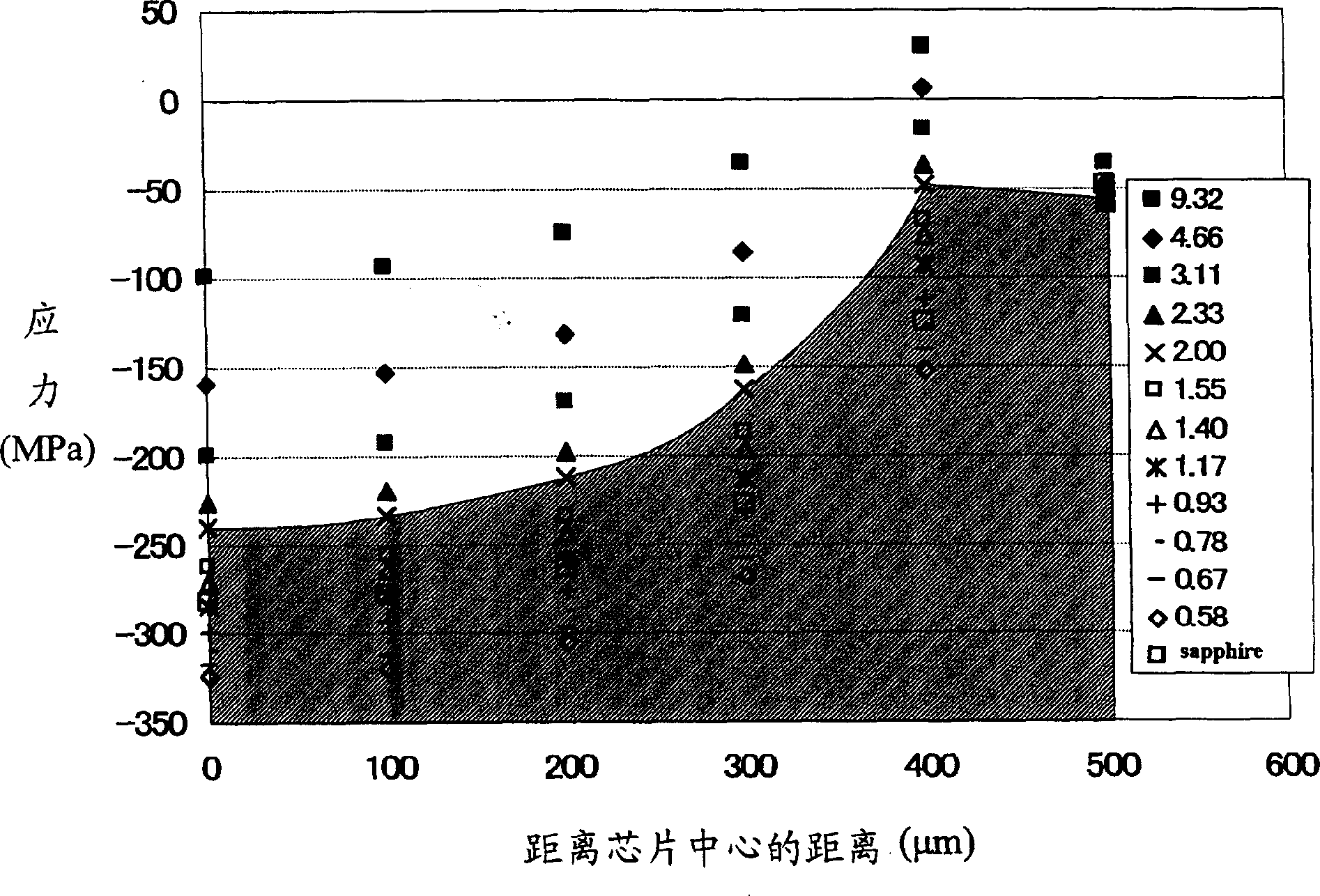

[0035] figure 1 is a perspective view of a model of the bonded substrate 100 used in the first embodiment of the present invention. Figure 2 to Figure 4 Each is a graph showing the results of analytical simulation of the bonded substrate 100 using the finite element method.

[0036] refer to figure 1 , the model of the bonded substrate 100 has a support substrate 20 and a main substrate or piezoelectric substrate 10 . The support substrate 20 is 1.0 mm long in the SAW propagation direction (X direction), 0.6 mm long in the direction perpendicular to the SAW propagation direction (Y direction), and 0.3 mm thick in the thickness direction (Z direction). A piezoelectric substrate 10 having a given thickness is bonded to the main surface of a support substrate 20 . The piezoelectric substrate 10 has a SAW resonator 30 formed thereon (see Figure 9 ), and a second surface opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com