Method for forming image on object surface including circuit substrate

A technology for circuit substrates and multilayer circuit substrates, applied to the removal of conductive materials by discharge methods, printed circuits, and printed circuit manufacturing, which can solve unavoidable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

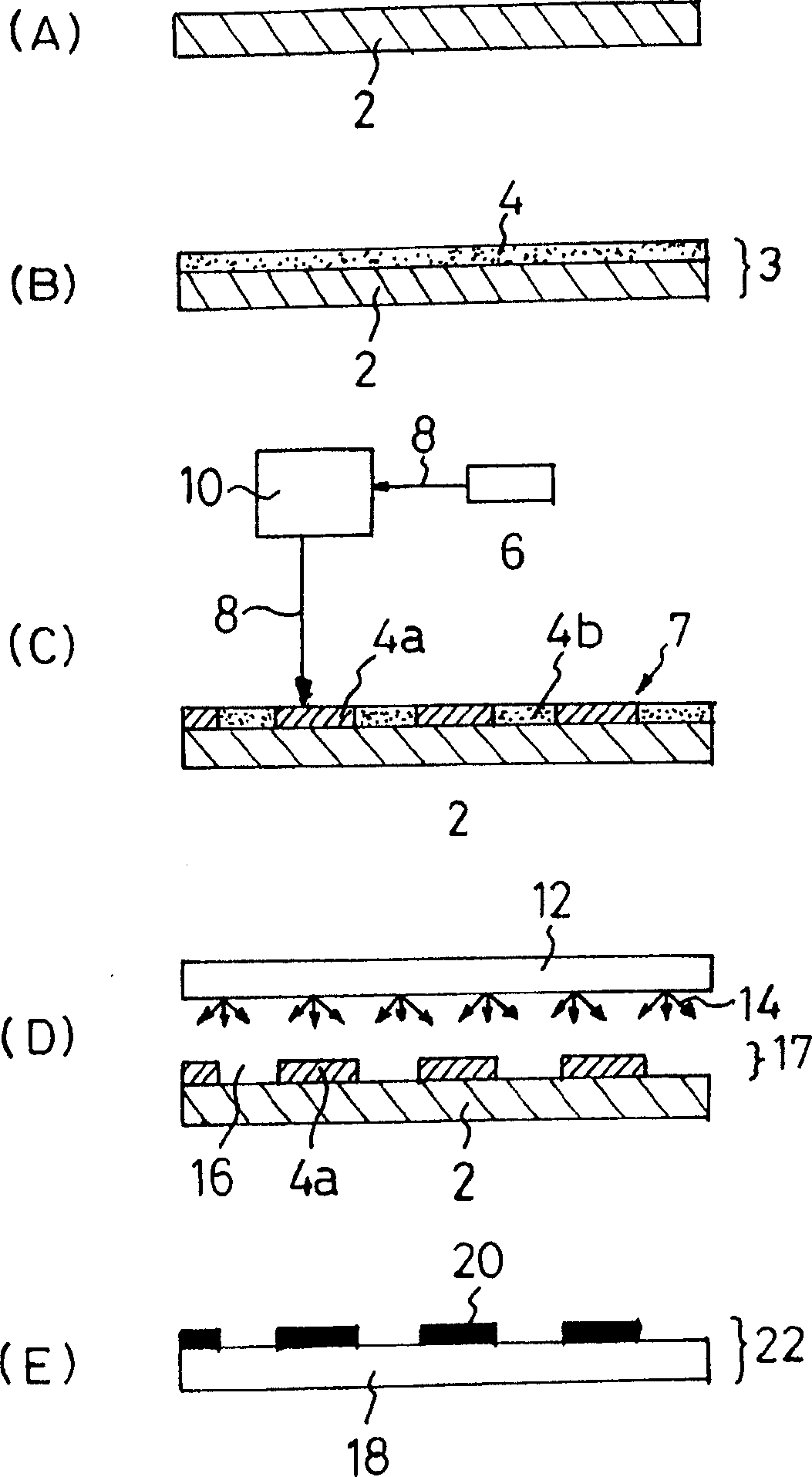

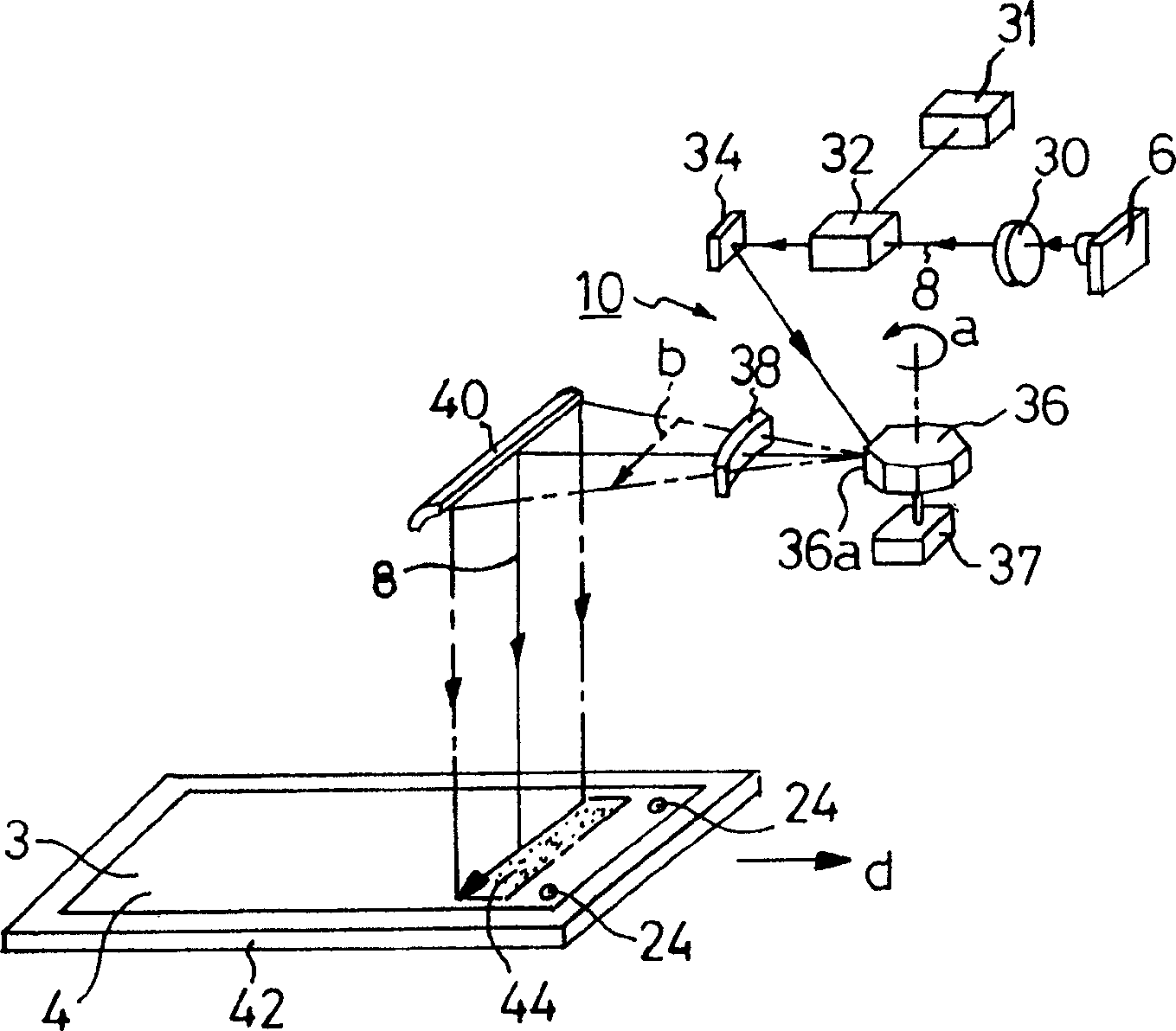

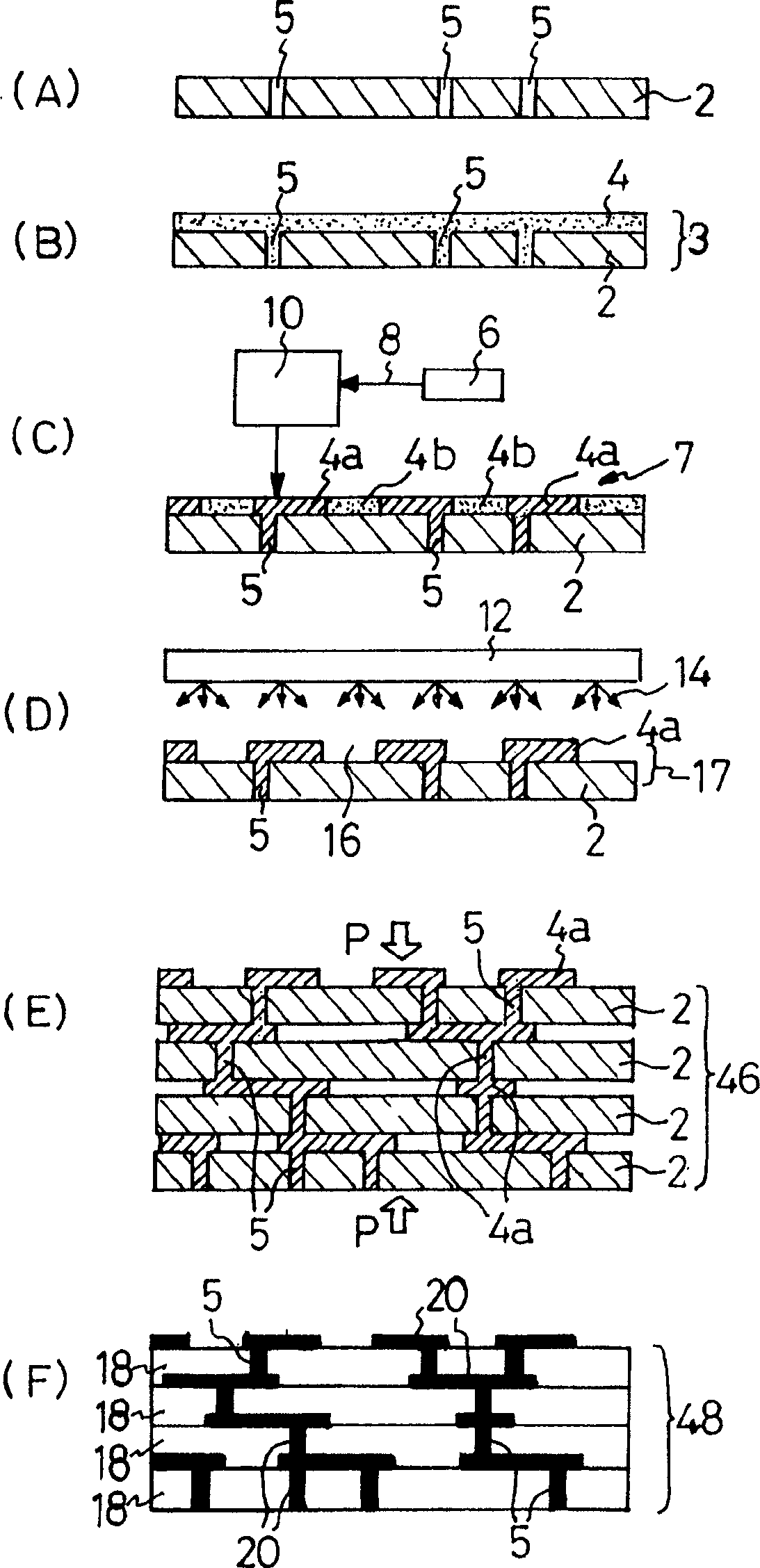

[0042] Hereinafter, embodiments of the circuit board manufacturing method of the present invention will be described in detail with reference to the drawings.

[0043] figure 1 It is a manufacturing process diagram of the single-layer type circuit board as the first embodiment of the present invention. In the step (A), the green sheet 2 to be a circuit board is placed at a predetermined position. First, adjust the ceramic powder that will become the raw material sheet 2 preparation. As for the ceramic powder, various materials can be used. For example, mix CaO·Al at a weight ratio of 60:40 2 o 3 ·B 2 o 3 ·SiO2 2 A mixture of borosilicate glass powder and alumina powder is also acceptable.

[0044] Form the ceramic powder into a paste with an organic solvent, an organic binder, and a plasticizer. For example, use a doctor blade method to form the paste into a sheet with a thickness of 1-300 μm, and roll it up to form a raw material tape. This raw material tape is cut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com