High-sponyiness, salt-resistant high-water-absorption resin preparation and method

A modification and formulation technology, applied in the field of preparation of high-porosity salt-tolerant superabsorbent resin, can solve the problems of research literature, achievements and patent reports of high-porosity salt-tolerant superabsorbent resin, etc. Energy consumption and operators, increase production rate, meet the effect of salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

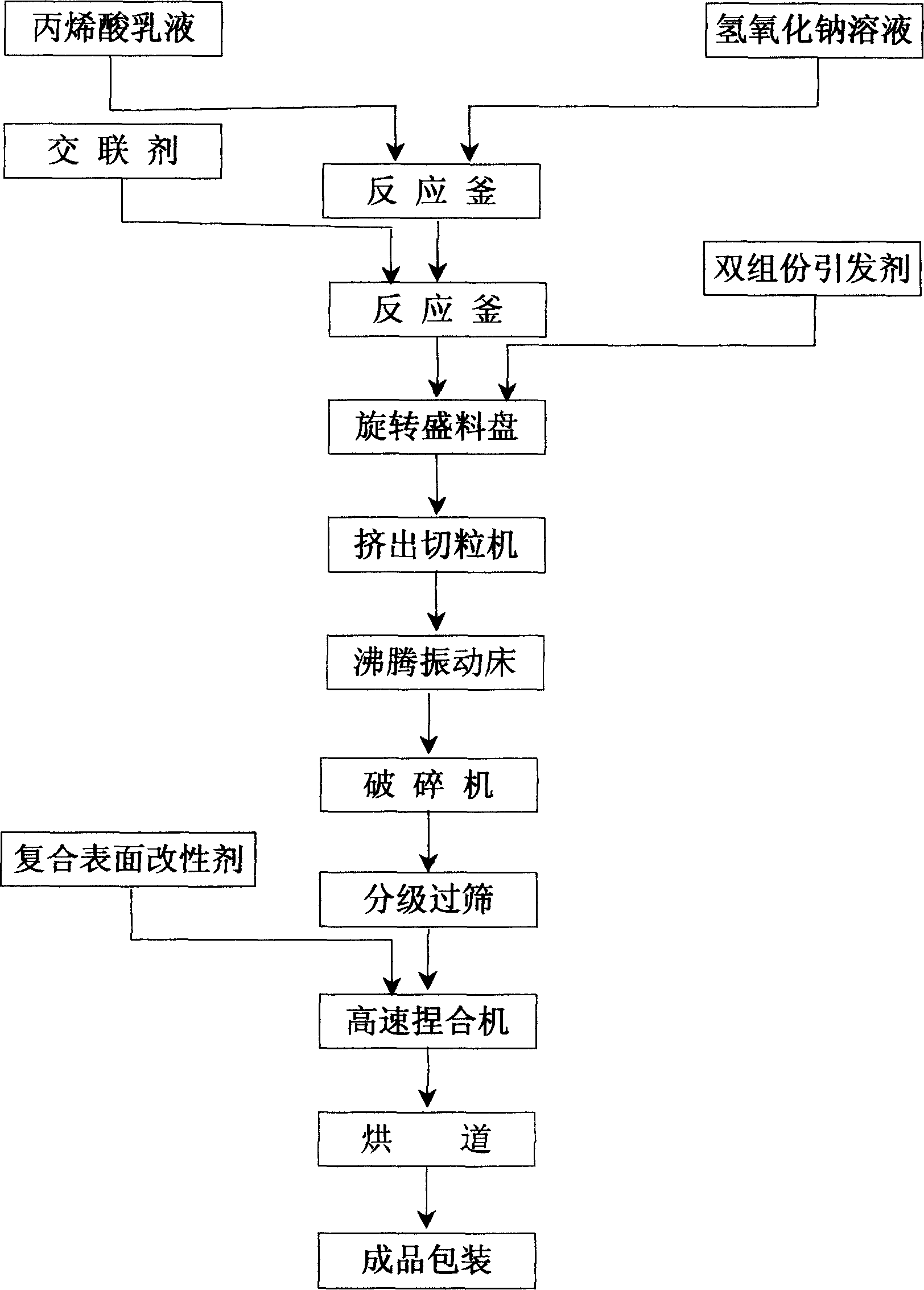

Image

Examples

Embodiment 1

[0016] Put 40kg of acrylic emulsion in the reaction kettle, start the mixer, dilute 18kg of sodium hydroxide with pure water to 72kg of solution, and slowly add the sodium hydroxide solution into the reaction kettle, control the temperature at 80°C, and neutralize for 13 minutes. Add 23g of cross-linking agent, stir for 5 to 8 minutes, measure and put it into the rotating pan, add 18g of two-component initiator to initiate cross-linking polymerization, and wait for the reactant to become a gel, place it in the extrusion cutting machine Cut into granules of φ2×3mm in the granulator, dry them in a fluidized vibrating bed at 130°C, put them in a crusher for crushing, screen out 80-mesh granules, put them in a high-speed kneader, add 250g of compound surfactants Carry out surface modification (stirring speed 500r.p.m, temperature 80±2°C, time 10min), and then dry in a drying tunnel at 120°C to become a finished product of superabsorbent resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com