Defect detector, defect detecting method and method for detecting hole figure

A defect inspection and defect technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as noise formation, insufficient inspection, and deterioration of S/N ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

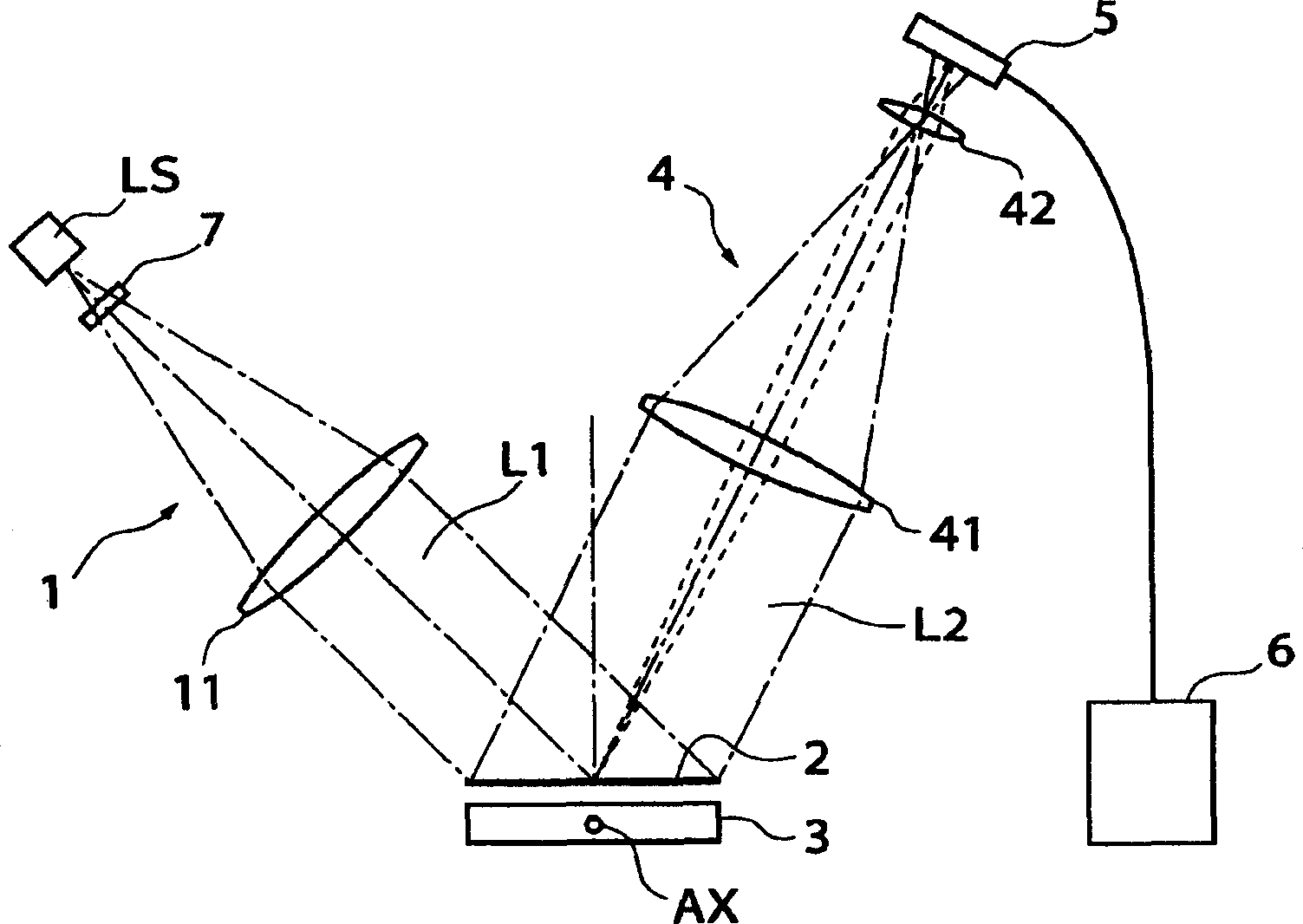

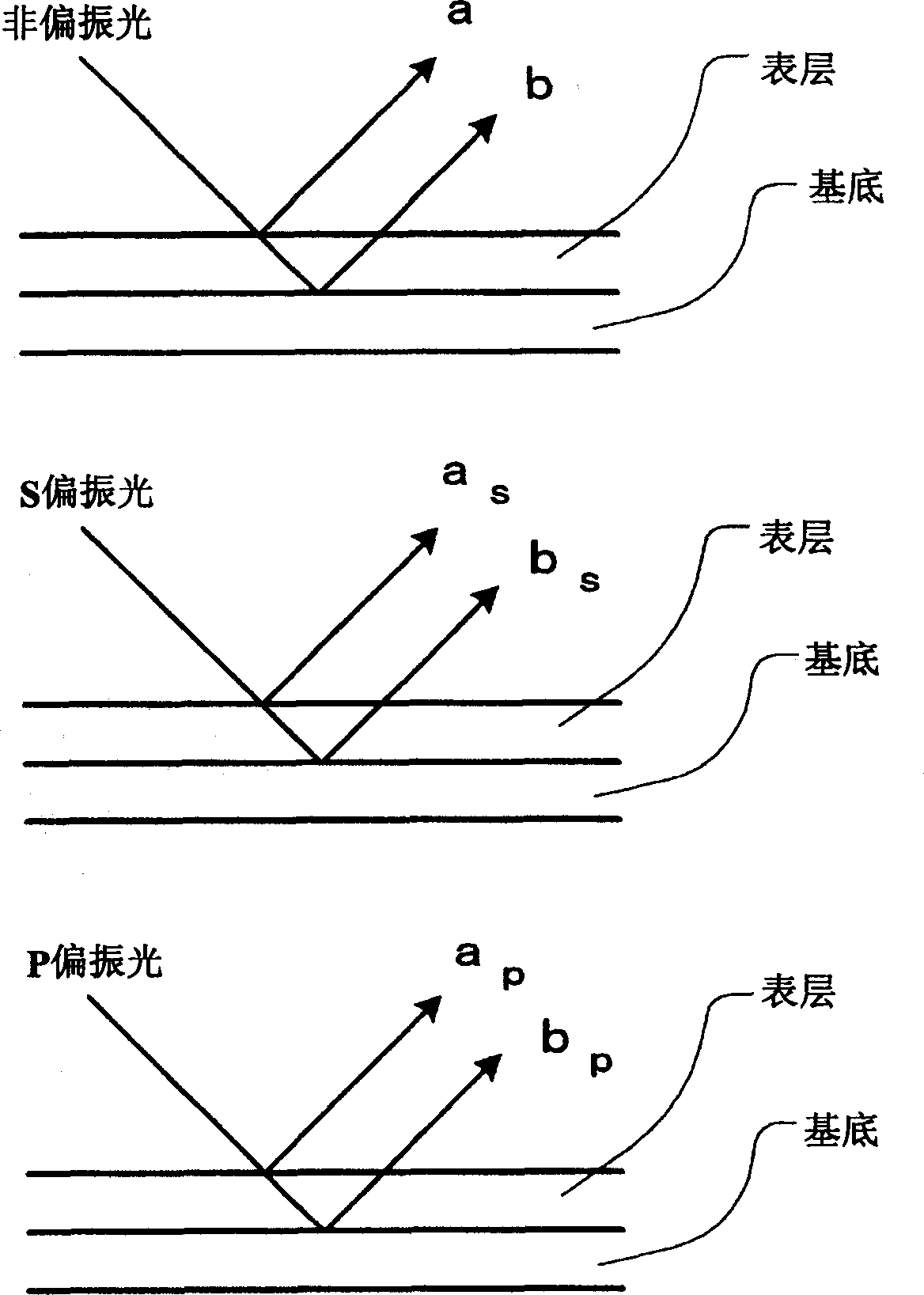

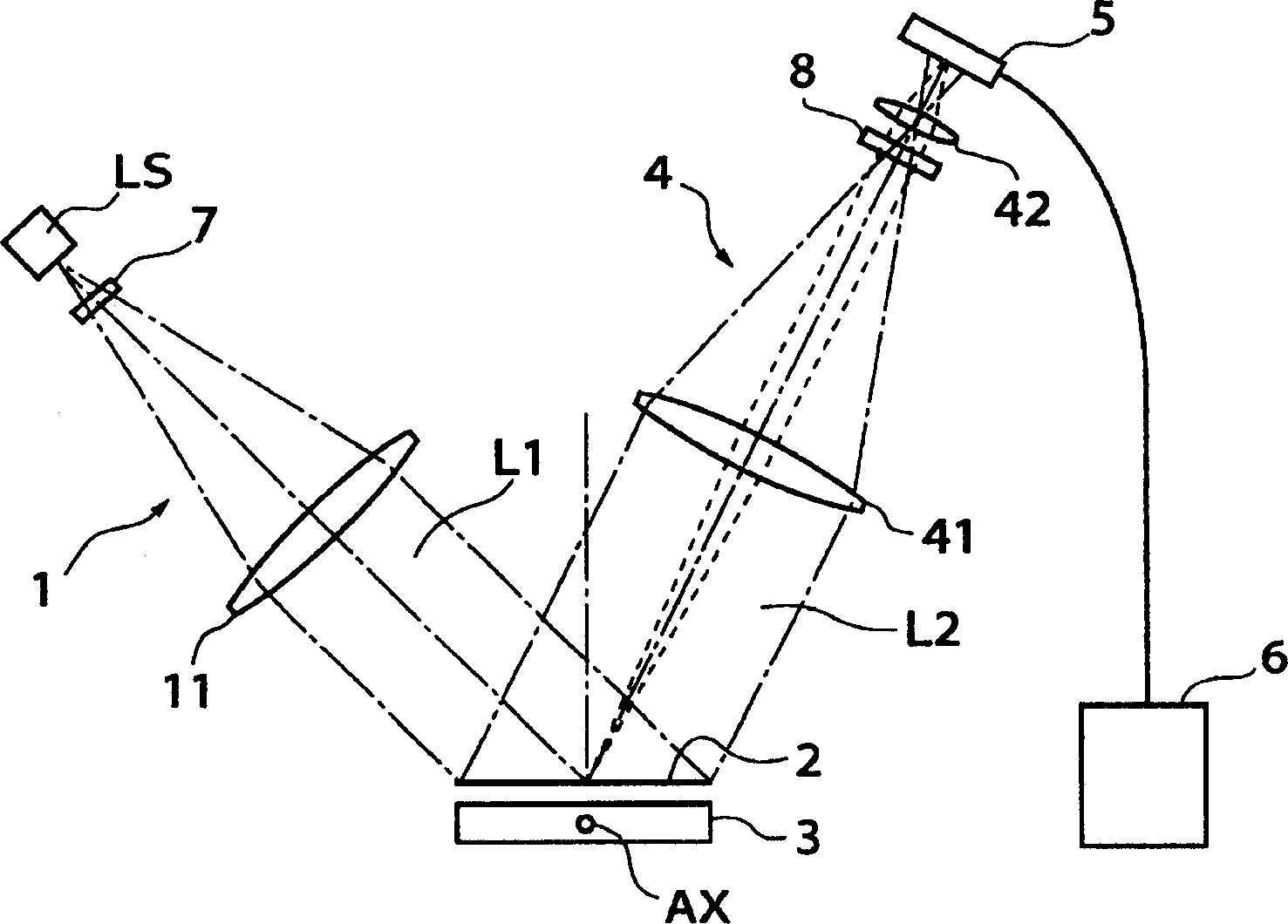

[0037] Examples of embodiments of the present invention will be described below using the drawings. figure 1 It is a schematic diagram of the defect inspection device according to the first embodiment of the present invention. The illumination light L1 emitted from the light source LS (lamphouse) is converted into substantially parallel light by the lens 11 constituting the illumination optical system 1 , and illuminates the wafer 2 placed on the stage 3 . A light source such as a halogen lamp or a metal halide lamp (not shown) and a wavelength selection filter are incorporated in the light source LS, and only light of a part of wavelength is used as illumination light L1.

[0038] The polarizing plate 7 is arranged in the vicinity of the emitting portion of the light source LS to make the illumination light L1 emitted from the light source LS linearly polarized. The polarizing plate 7 can rotate around the optical axis of the illumination optical system 1 to arbitrarily cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com