Lead-based alloy for lead acid battery substrate for lead acid battery and lead-acid battery

A technology of lead-acid batteries and lead-based alloys, which is applied in the field of lead-based alloys for lead-acid batteries, substrates for lead-acid batteries and lead-acid batteries to achieve excellent corrosion resistance, excellent mechanical strength, and high-current charging and discharging characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

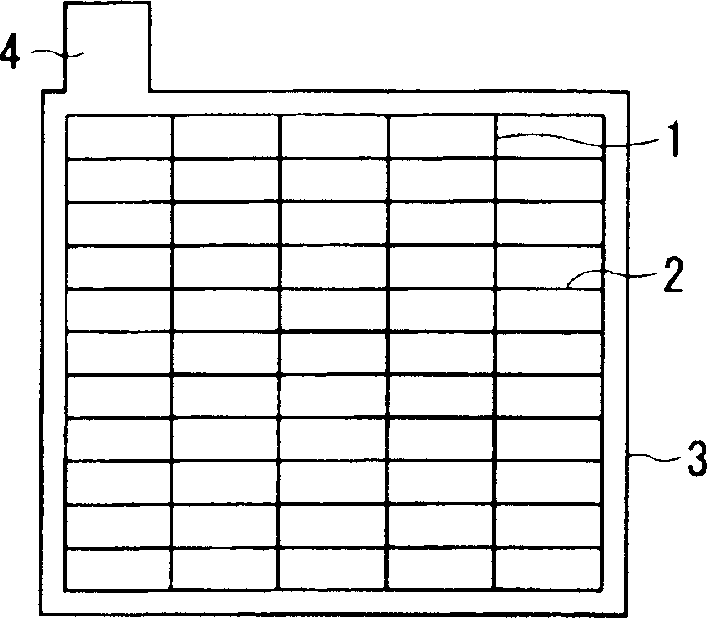

Image

Examples

Embodiment 1~7

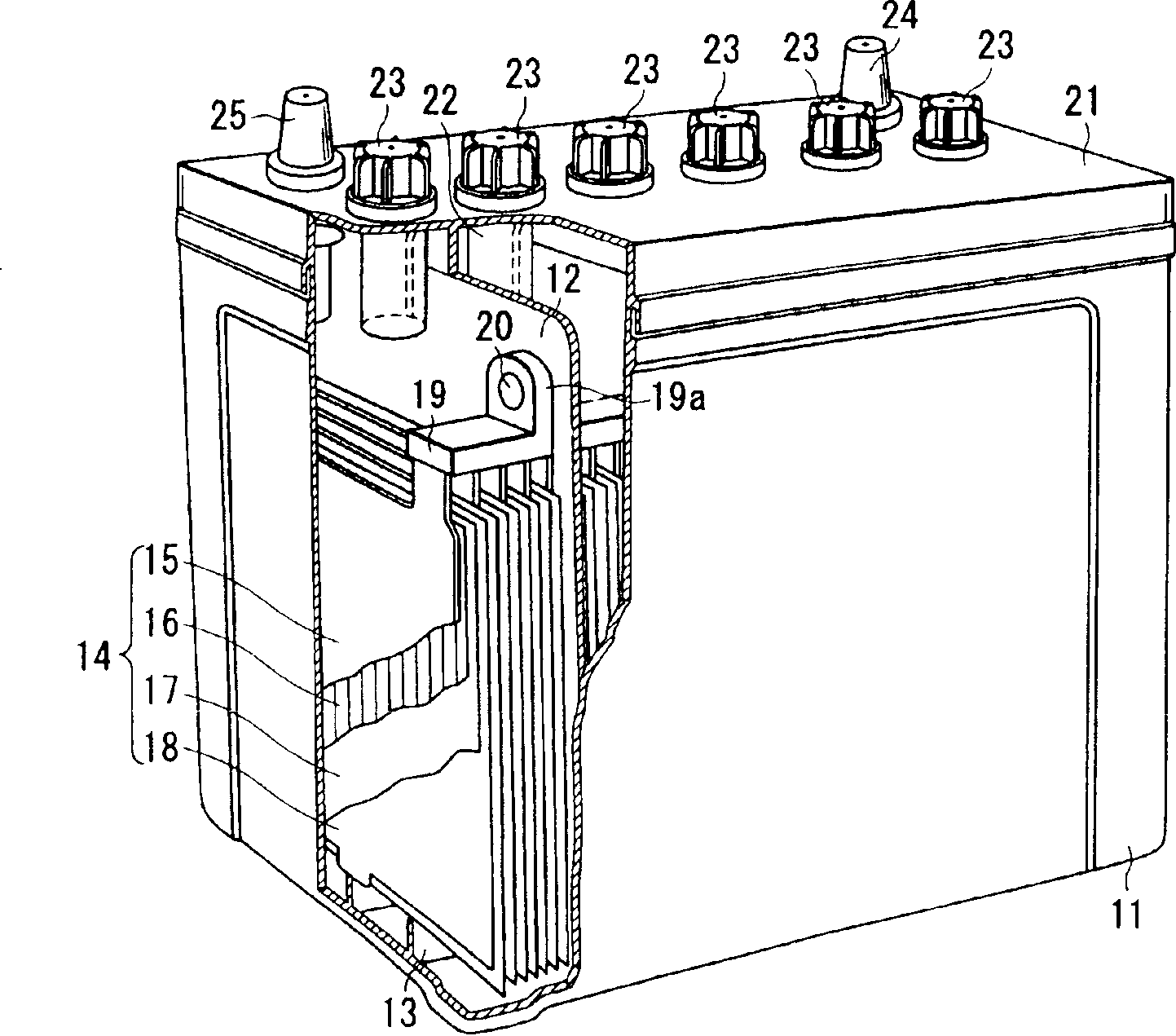

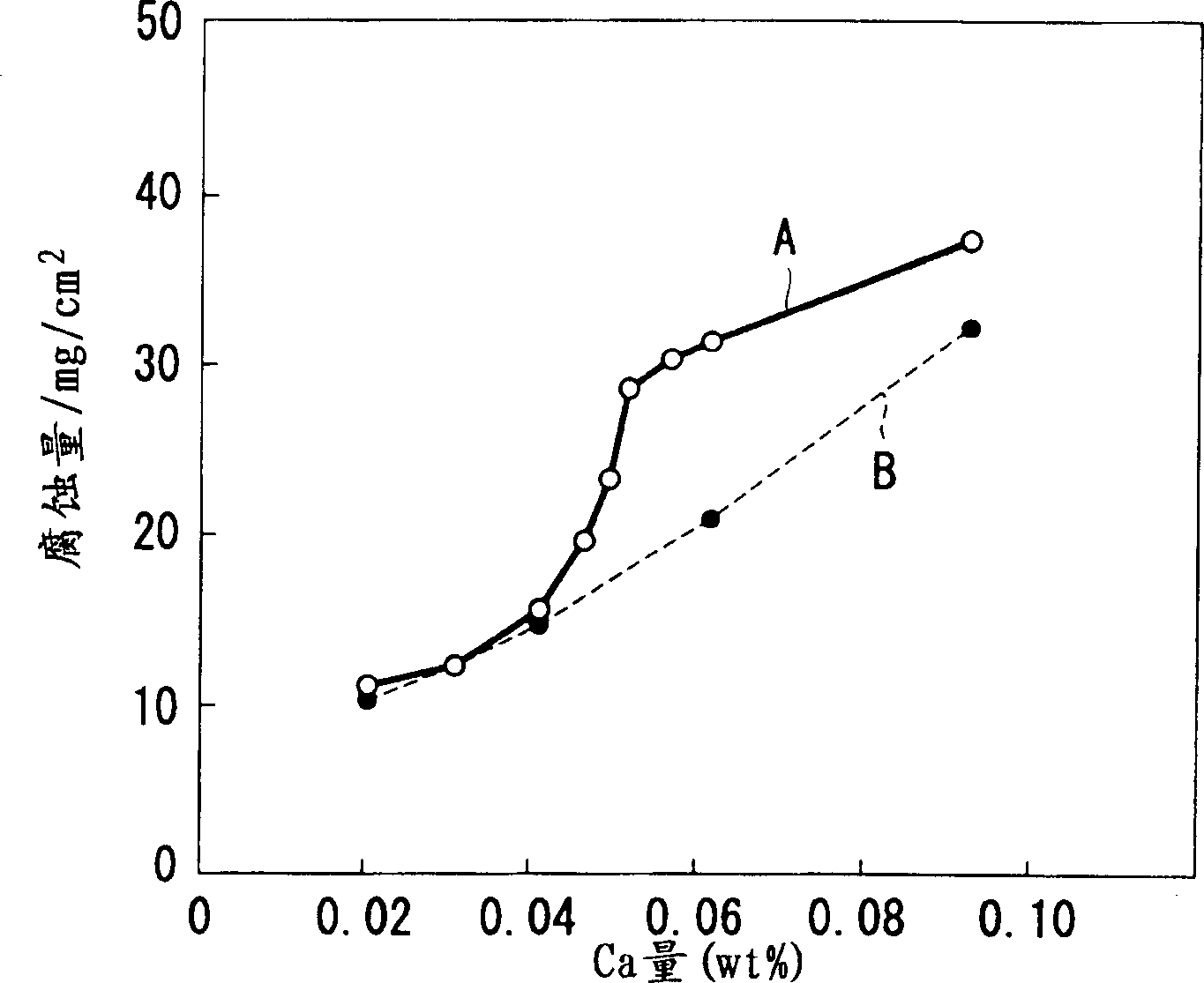

[0129] (Examples 1-7, Comparative Examples 1-5)

[0130] Twelve pairs of grid substrates having protrusions were produced by cassette die casting using 12 types of lead-based alloys having the compositions shown in Table 1 below (substantially Pb other than the components in Table 1). Casting takes place at a rate of 15 blocks per minute. Among the obtained pair of grid substrates, the grid substrates of Examples 1 to 7 were softer and more easily deformed than the grid substrates of Comparative Examples 1, 2, 4, and 5 having a large amount of Ca. For this reason, cooling air was blown after casting to remove unnecessary parts, and then heat treatment was performed on these substrates at 100° C. for 1 hour to age harden them.

[0131] Next, a positive electrode paste obtained by mixing and stirring PbO powder and sulfuric acid aqueous solution was filled into the pair of grid substrates by a well-known method. In this step, deformation of the grid substrates of Examples 1 to...

Embodiment 8、9 and comparative example 6、7

[0138] Cast ingots composed of four types of lead-based alloys having the compositions shown in Table 2 below (substantially Pb other than the components in Table 2) were rolled to produce four types of alloy plates with a thickness of 0.9 mm. These alloy plates are expanded to become expanded substrates. These expanded substrates were filled with a positive electrode paste obtained by mixing and stirring PbO powder and sulfuric acid aqueous solution by a well-known method, and then cured for 24 hours in an atmosphere at a temperature of 40° C. and a humidity of 95%. Then, it was dried to make four kinds of positive electrode cured plates.

[0139] The obtained positive electrode solidified plates are respectively combined with the negative electrode solidified plates by means of stopper base separators made of fine glass fibers (by a well-known method, a grid substrate made of Pb-Ca-Sn is filled with an aqueous sulfuric acid solution). PbO powder and additives such as lignin...

Embodiment 10~13

[0144] A cast substrate (grid substrate) was produced from a cassette mold using a lead-based alloy of Ca 0.040 wt%, Sn 1.00 wt%, Al 0.020 wt%, Ba 0.008 wt%, and the balance being Pb. The casting was performed at a rate of 15 blocks per minute. The resulting grid substrate was subjected to heat treatment for 1 hour (Example 10), 1.5 hours (Example 11), 3 hours (Example 12) and 10 hours (Example 13) at various temperatures .

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com