Method for recycling paper and plastic from waste product of one-off paper and plastic health aids

A sanitary product and disposable technology, which is applied in the field of paper and plastic recycling from the waste of disposable paper-plastic sanitary products, can solve the problems of harmful gas pollution to the atmospheric environment, white pollution of the environment, waste of raw materials, etc., and achieve good economic benefits and great development. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

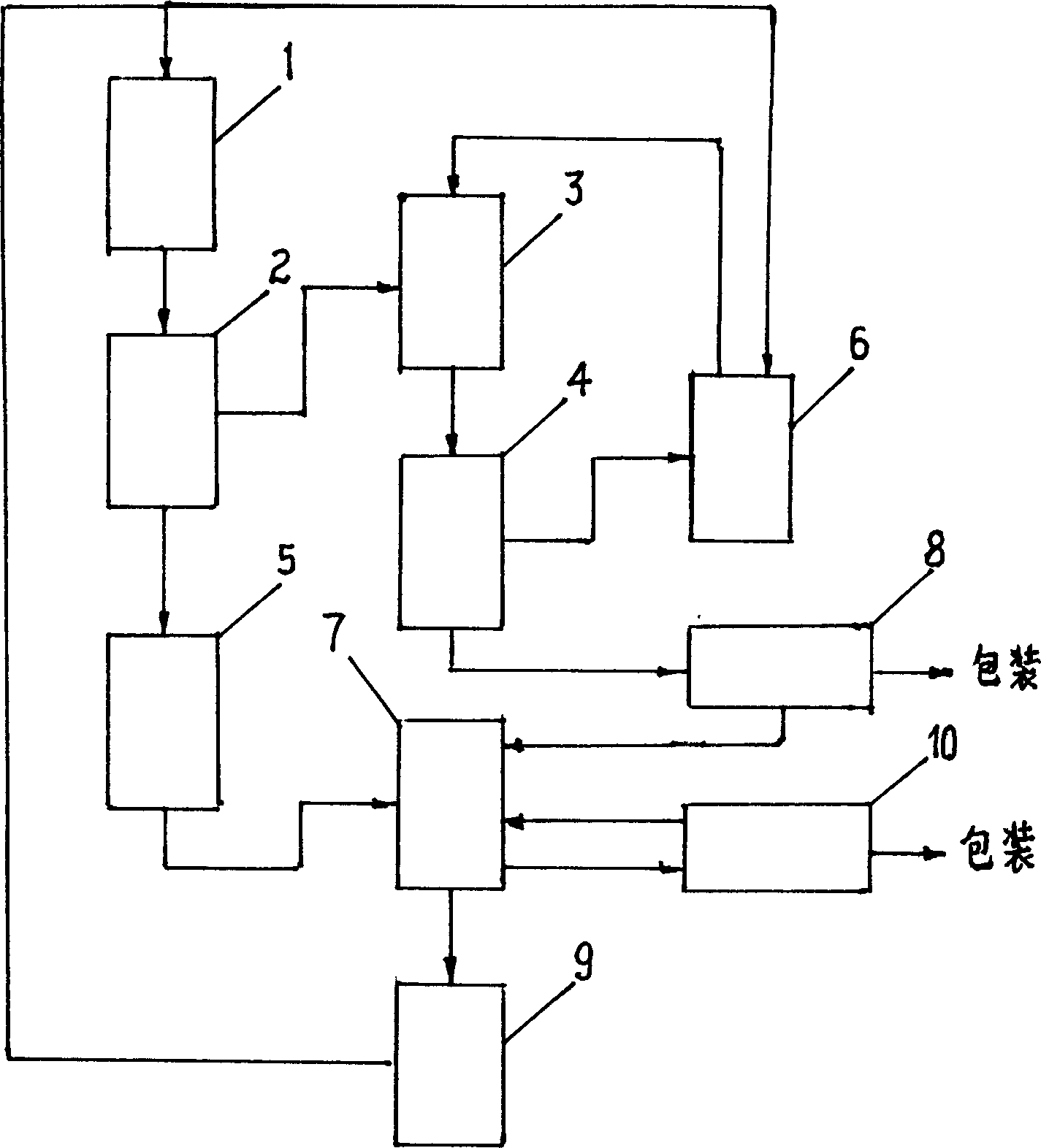

Method used

Image

Examples

Embodiment Construction

[0018] The specific design and operating parameters of the present invention are related to the type and daily processing capacity of waste materials.

[0019] 1. If the daily processing capacity of waste is about 1 ton, and the ratio of paper and plastic is 6:4, the power of the heating furnace is about 300,000 kcal / hour, and the volume of the agitator and dehydrator is 0.5m 3 Around, pulp oven volume is 9m 3 Around, the volume of the plastic oven is 4m 3 About, the volume of the reactor is 2m 3 About, the still volume is 5m 3 About, the power of the vacuum pump is about 3kW. The specific steps are:

[0020] 1) Heat the system to 80°C-150°C.

[0021] 2) Put the paper and plastic waste into the mixer 1, put the reagent into the mixer 1, stir and heat, and then put the materials into the separator 2.

[0022] 3) Adjust the rotating speed of the separator 2 to separate the solid and liquid, and send them to the stirring cleaner 3 and the distillation kettle respectively.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com