Lamb ferment rennet ultrasonic extraction method

An extraction method and rennet enzyme technology, which are applied in the field of protease, can solve the problems of high microbial contamination, spoilage of abomasum raw materials, and impact on product quality, and achieve high extraction efficiency, low microbial contamination of products, and shortened extraction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

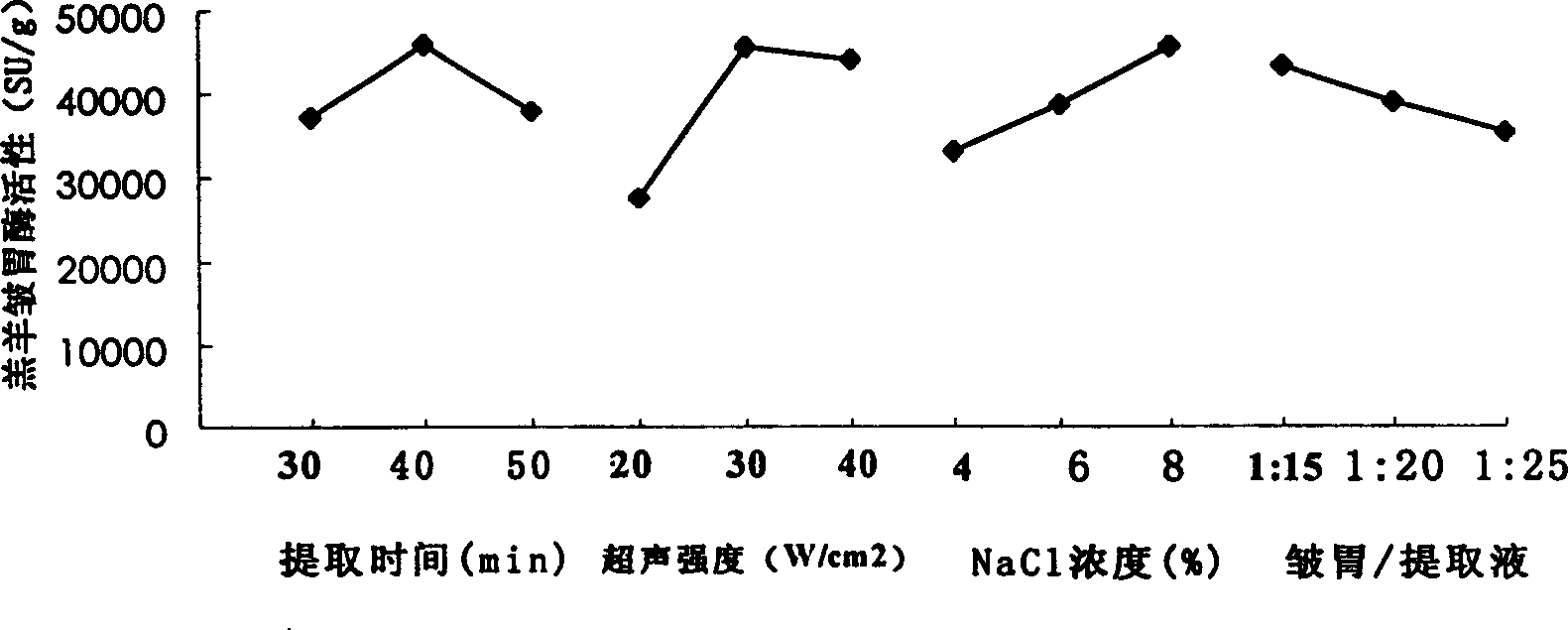

Method used

Image

Examples

Embodiment 1

[0027] The processing steps of the lamb rennet enzyme ultrasonic extraction method of the present embodiment are as follows:

[0028] 1. Pretreatment of lamb abomasum

[0029] After the lamb is slaughtered, take out the abomasum immediately, rinse it with running water for 1-2 minutes to remove the contents, then peel off the fat and connective tissue outside the abomasum, and freeze it at -24°C for later use.

[0030] 2. Chopped lamb abomasum

[0031] Use a meat grinder to cut the lamb abomasum into 0.001-0.01cm 3 lamb abomasum pieces.

[0032] 3. Ultrasonic extraction

[0033] Add 8% NaCl to the phosphate buffer with a pH value of 4 to prepare NaCl leaching buffer, put the NaCl leaching buffer into the container of the ultrasonic extractor, and then add cut The crushed lamb abomasum, so that the weight ratio of the lamb abomasum and the buffer solution is 1:15, and the ultrasonic frequency is 20KHz, and the ultrasonic intensity is 40W / cm 2 , extract for 40 minutes, and ...

Embodiment 2

[0041] In the ultrasonic extraction process step of this embodiment, 2% NaCl is added to the phosphate buffer solution with a pH value of 2.0 to prepare a NaCl extraction buffer, and the NaCl extraction buffer is loaded into the container of the ultrasonic extraction device, Then add the chopped lamb abomasum to the leaching buffer so that the weight ratio of the lamb abomasum to the buffer is 1:10, and the ultrasonic frequency is 20KHz and the ultrasonic intensity is 20W / cm 2 , extract for 20 minutes, and keep the temperature of the extract at 20-25°C. Other process steps in this embodiment are the same as in Embodiment 1.

Embodiment 3

[0043] In the ultrasonic extraction process step of this embodiment, 10% NaCl is added to the phosphate buffer solution with a pH value of 5.0 to prepare a NaCl extraction buffer, and the NaCl extraction buffer is loaded into the container of the ultrasonic extraction device, Then add the chopped lamb abomasum to the leaching buffer so that the weight ratio of the lamb abomasum to the buffer is 1:25, and the ultrasonic frequency is 20KHz and the ultrasonic intensity is 45W / cm 2 , extract for 50 minutes, and keep the temperature of the extract at 20-25°C. Other process steps in this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com