Turbocharger comprising a torsional-vibration damper

A technology of torsional vibration and supercharger, applied in the direction of rotation vibration suppression, engine function, engine components, etc., can solve problems such as power loss, and achieve good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

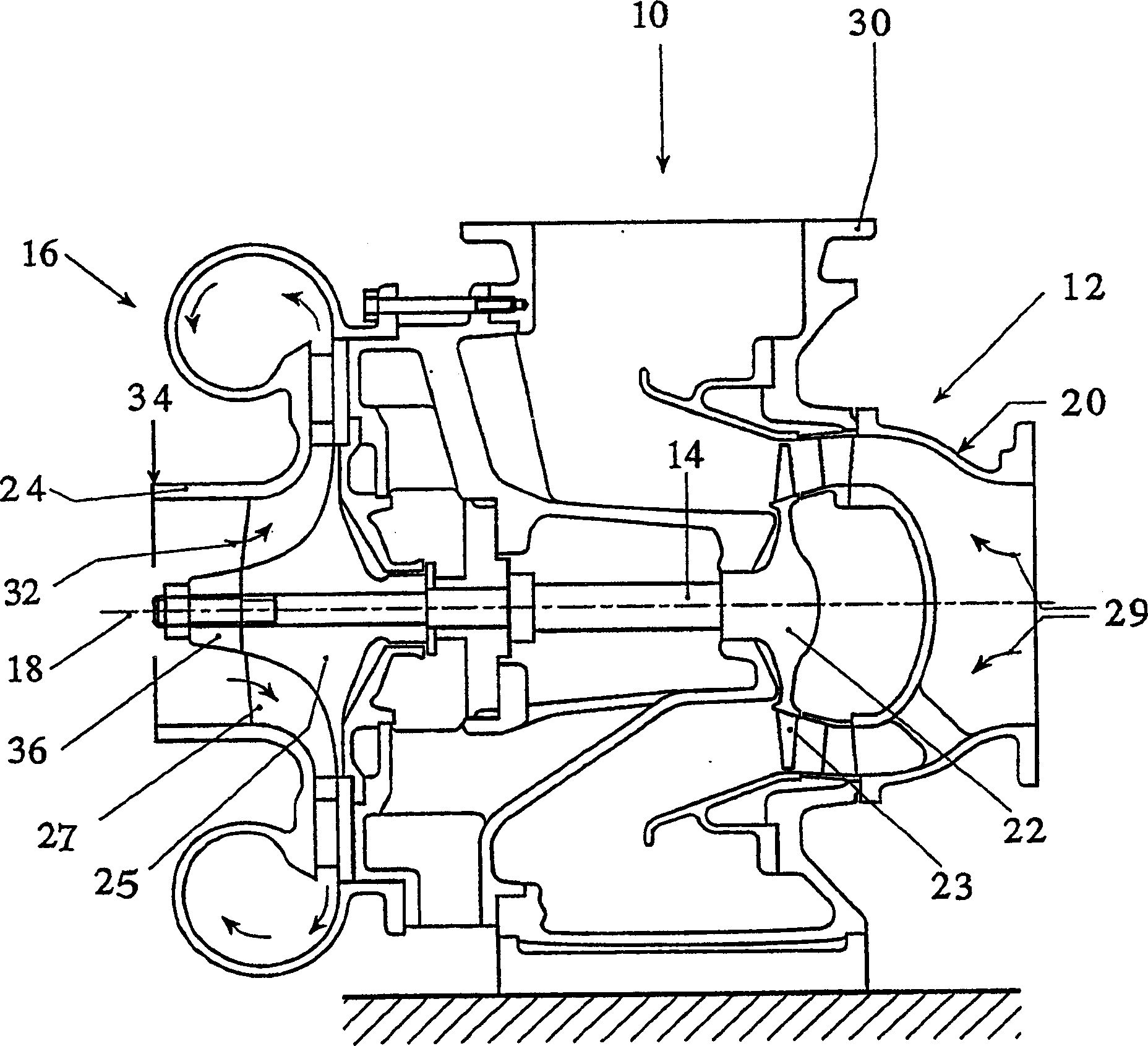

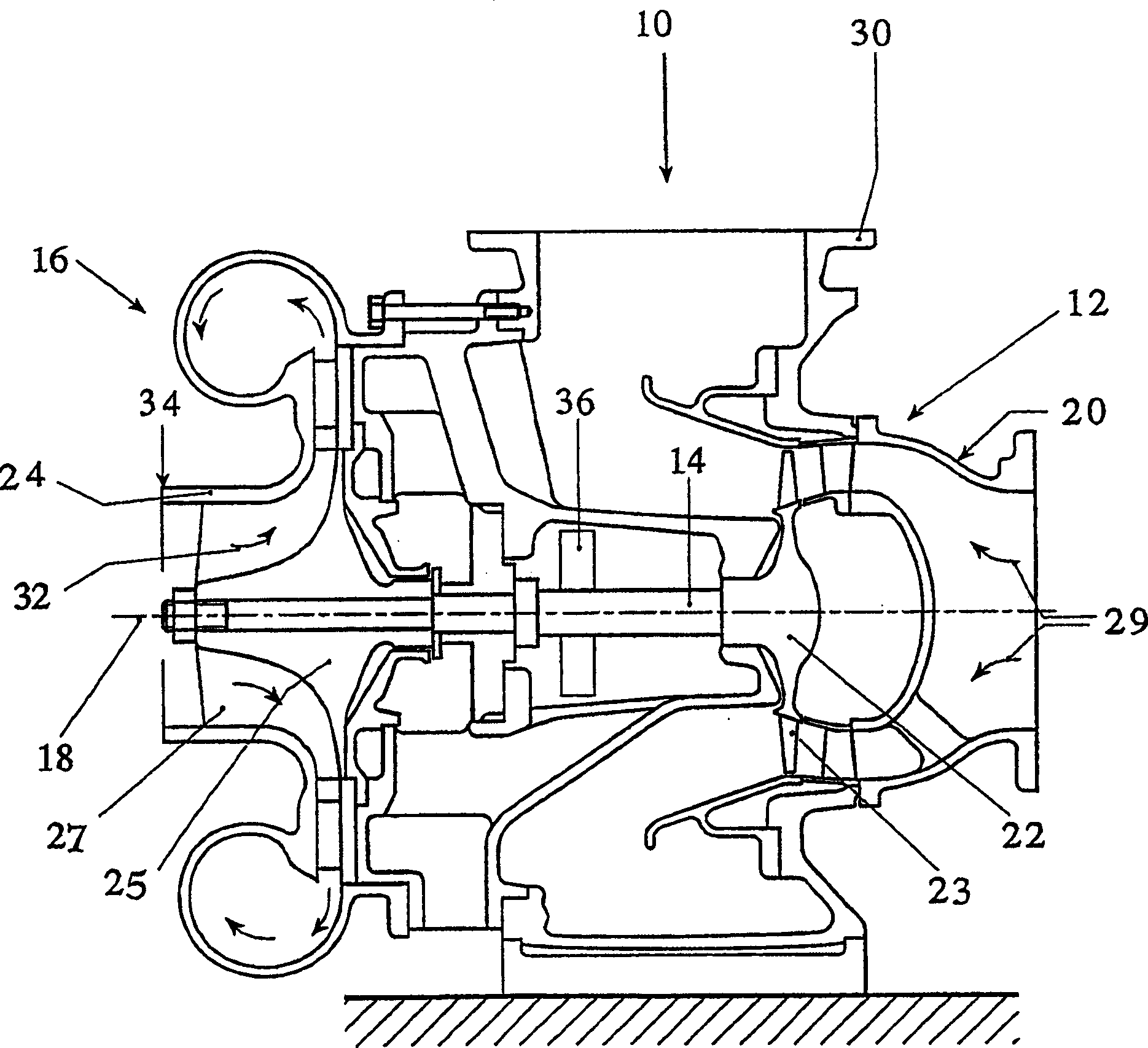

[0022] figure 1 and 2 Each shows a cross-sectional view of a turbocharger 10 with a high-speed rotating electric machine unit 11 along their longitudinal axis 18 . Each high speed rotating electric machine unit 11 comprises a turbine 12 and a compressor 16 which are connected to each other by a common turbocharger shaft 14 . The turbine 12 has a turbine wheel 22 surrounding a turbine housing 20 with turbine blades 23 . The compressor wheel 26 has compressor blades 27 which are regularly distributed around the compressor hub 25 . A compressor wheel 26 peripherally surrounds the compressor casing 24 and is driven by the turbine 12 by means of the common shaft 14 . The common turbocharger shaft 14 is supported between a compressor wheel 26 and the turbine wheel 22 in a bearing bracket 28 .

[0023] The turbine mount 20 forms a flow duct 29 which is connected to the exhaust pipe of the internal combustion engine (not shown). The air flow duct 29 leads through the turbine 22 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com