Method for preparing nanometer ultra-fine tourmaline powder

A technology of tourmaline micropowder and tourmaline powder, applied in chemical instruments and methods, lighting and heating equipment, inorganic chemistry, etc., can solve the problems of large particle size, complicated process, large particle size of powder, etc., and achieve the improvement of generating capacity, The process is easy to operate and the effect of improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

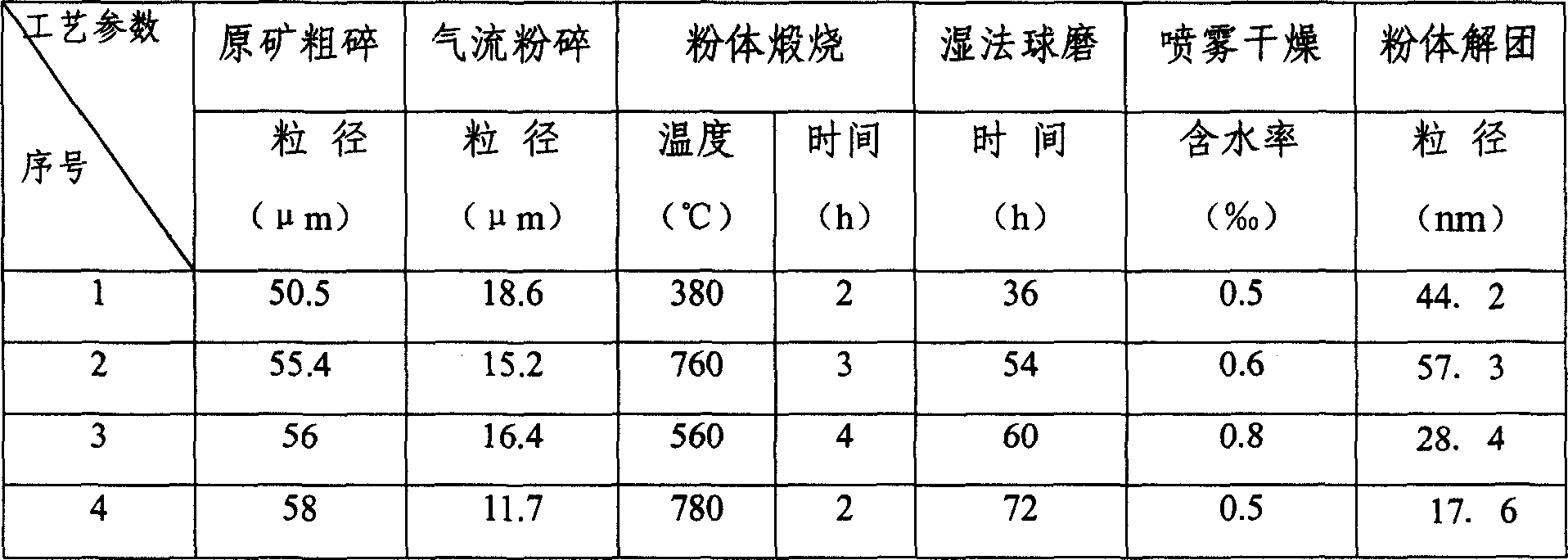

[0023] Using the preparation method of the present invention, according to the technological process of crude ore crushing, jet crushing, powder post-treatment, wet ball milling, spray drying, powder deagglomeration, packaging and storage, prepared 4 batches of 1-4# Nanoscale ultrafine tourmaline powder. The technical and process parameters of the mining and the rough crushing of tourmaline raw ore, jet milling and final particle size are listed in Table 1. The composition ratio of tourmaline, grinding medium, grinding aid and dispersant in the technological process is listed in Table 2. The chemical composition and color of the nanoscale ultrafine tourmaline that the present invention makes are listed in Table 3. The negative ion concentration and far-infrared emissivity of the nanoscale ultrafine tourmaline measured by the present invention are listed in Table 4. The far-infrared is tested by the School of Science of Tianjin University. The test instrument is a 5DX Fourier...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com