Elastic floating body and manufacturing method thereof

A floating body and elastic technology, applied in the direction of non-magnetic metal hulls, buoys, hulls, etc., can solve the problems of high follow-up cost, long maintenance-free time, low maintenance cost, etc., achieve excellent physical properties and processing performance, and long maintenance-free time , low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

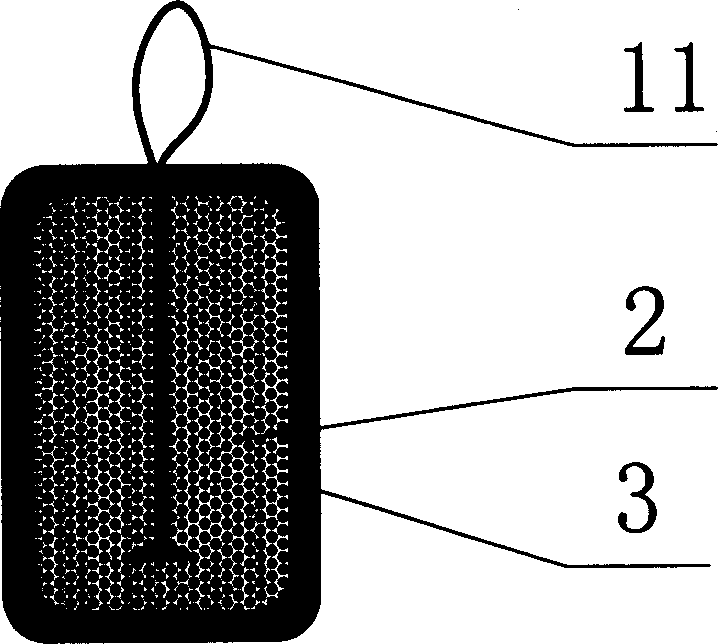

[0035] Such as figure 1 As shown, the present invention includes a floating body 1 which is composed of an elastic foam inner core 2 and an elastic armor 3 covering the surface of the elastic foam inner core 2. The elastic foam inner core 2 is made of a polymer foam material. The polymer material can be plastic or a mixture of plastic and rubber or polyurethane. The present invention uses one of plastics—EVA resin; the elastic armor 3 It is made of polyurethane or polyurea or a mixture of polyurethane and polyurea. The present invention uses a mixture of polyurethane and polyurea.

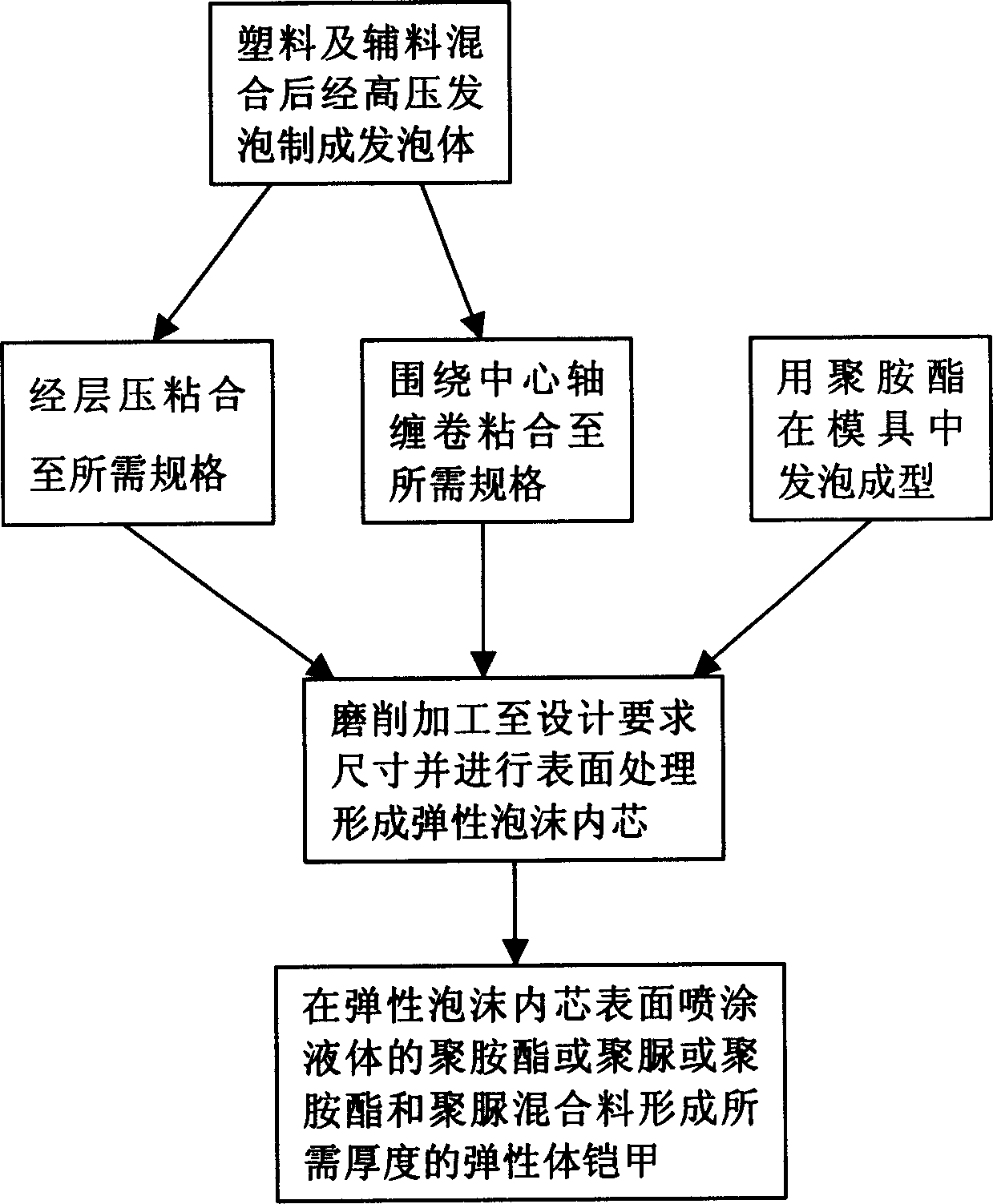

[0036] Such as figure 2 As shown, the manufacturing process steps of the present invention are as follows:

[0037] 1. First, make the elastic foam inner core 2.

[0038] 1. The inner core can be made of plastic foam inner core or polyurethane foam inner core.

[0039] 1) The production methods of plastic foam include molding method and extrusion method:

[0040] I. The molding method is to put plast...

Embodiment 2

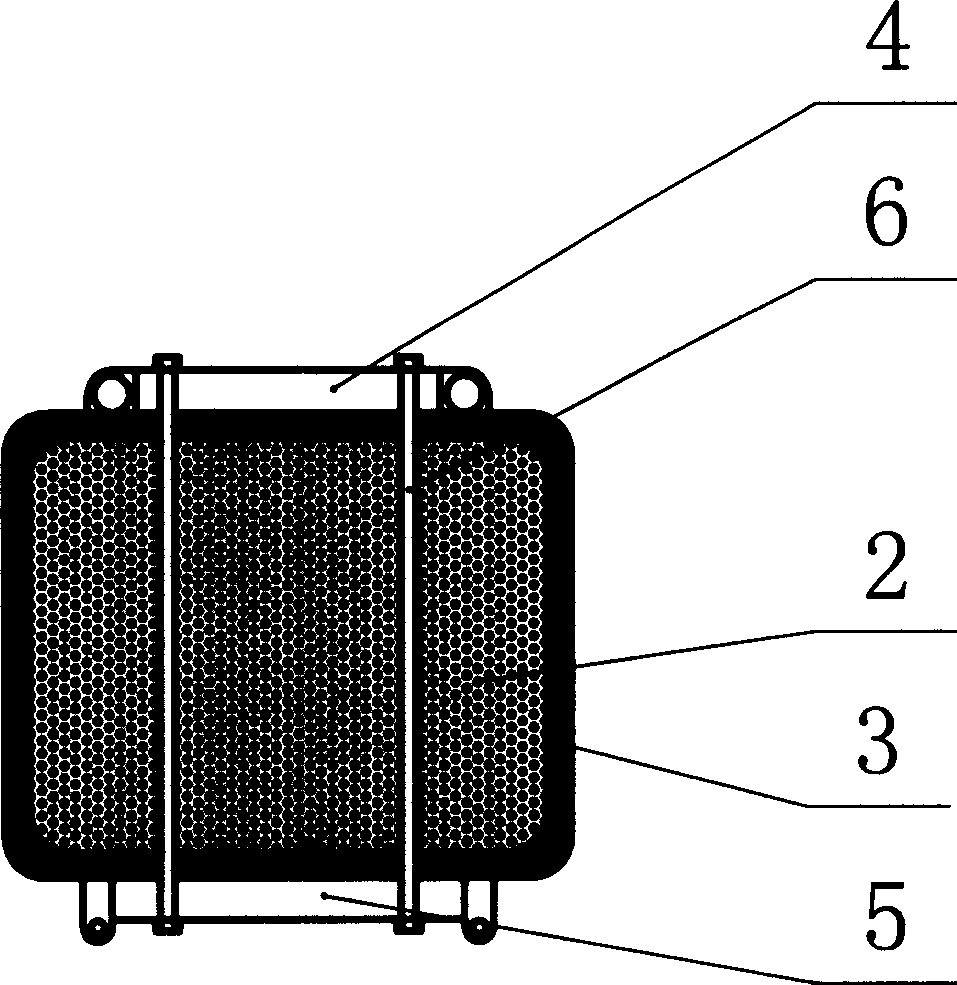

[0052] Such as image 3 As shown, for a slightly larger-sized elastic floating body, the present invention also includes an upper cover plate 4, a lower support plate 5, and four connecting rods 6.

[0053] During production, before spraying the elastic armor 3, drill 4 through holes on the molded elastic foam inner core 2 along a circle with the inner core center as the axis to install the connecting rod 6; set the upper part of the molded floating body 1 The upper cover 4 and the lower support plate 5 are provided, and the upper cover 4, the lower support plate 5 and the floating body 1 are connected as a whole by the connecting rod 6.

[0054] The other features are the same as the first embodiment.

Embodiment 3

[0056] Such as Figure 4 As shown, for an elastic floating body with a larger specification, the present invention also includes an upper cover plate 4, a lower support plate 5, and a center tube 7.

[0057] During production, before spraying the elastic armor 3, drill a through hole in the center of the formed elastic foam core 2 and install the center tube 7; The tube 7 is tightly connected, and the upper cover 4, the lower support plate 5 and the floating body 1 are connected as a whole through the central tube 7.

[0058] The other features are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com