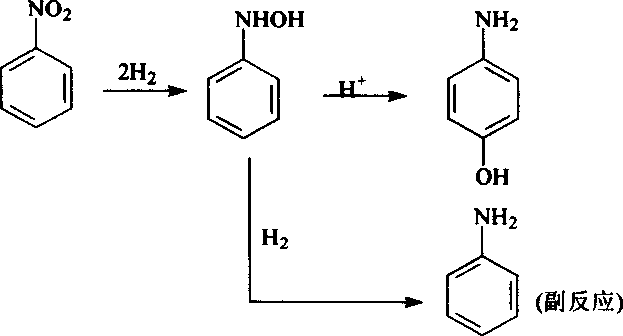

Load type catalyzer for synthesizing p-aminophenol, preparation method and method of application

A supported catalyst and p-aminophenol technology, applied in the preparation of amino hydroxyl compounds, organic compounds, chemical instruments and methods, etc., to achieve the effects of high mechanical strength, high strength, easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation of supported catalyst, the steps are as follows:

[0031] (1) SiO will be used as a carrier 2 Put it in a muffle furnace and bake at 200-750°C for 1-6 hours, and set aside;

[0032] (2) Weigh 3g of roasted SiO 2 Carrier, use deionized water to measure the volume of impregnating solution required for equal volume impregnation is 5mL;

[0033] (3) Weigh 0.1g catalyst precursor H 2 PtCl 6 Dissolve in 5mL of water or ethanol aqueous solution with a concentration of 20% to 50% by weight to make an impregnation solution;

[0034] (4) Weigh 3g of roasted SiO 2 The carrier is impregnated with an equal volume of 5 mL of the above impregnating solution for 5 to 25 hours;

[0035] (5) Vacuum drying the impregnated catalyst at 35-120° C. for 0.5-20 hours;

[0036] (6) placing the above-mentioned dried catalyst in a muffle furnace and roasting at 200-550° C. for 1-5 hours in a nitrogen atmosphere or an air atmosphere;

[0037] (7) The above-mentioned catalyst...

Embodiment 2

[0039] Weigh the catalyst parent agent H 2 PtCl 6 0.1g and additive RuCl 3 0.1g is dissolved in water or the ethanol aqueous solution of 20%~50% concentration by weight percentage is made into impregnation solution, other is the same as embodiment 1, can make supported catalyst Pt-Ru / SiO 2 .

Embodiment 3

[0041] Weigh the catalyst parent agent H 2 PtCl 6 0.1g and additive Co(NO 3 ) 2 0.5g is dissolved in water or the ethanol aqueous solution of 20%~50% concentration by weight percentage is made into impregnation solution, other is the same as embodiment 1, can make supported catalyst Pt-Co / SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com