Heat carrier stove using solid fuel

A technology for solid fuel and heat carrier furnaces, applied in fluid heaters, combustion methods, and controlled combustion, can solve unrealistic problems and achieve the effects of convenient operation, low preparation cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

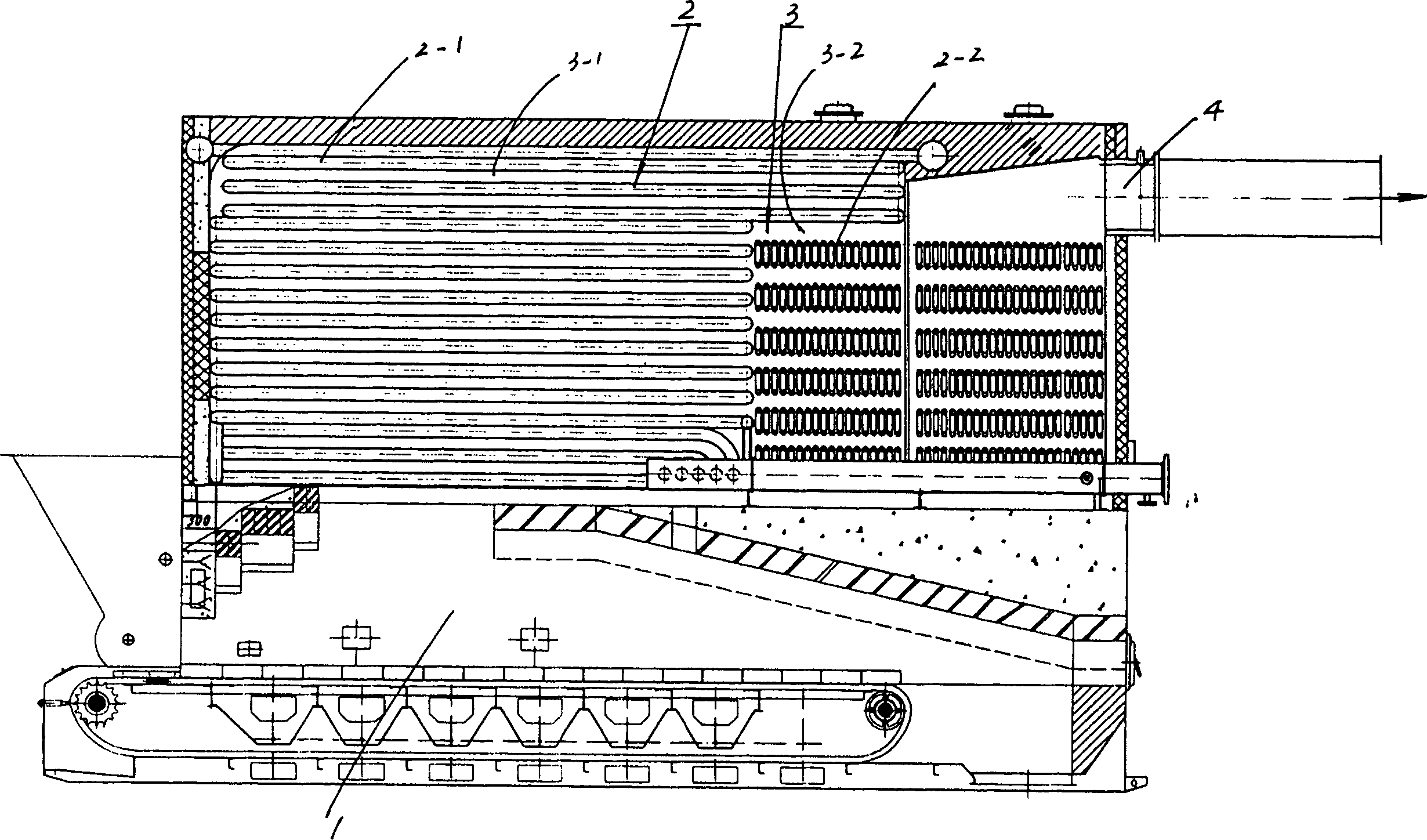

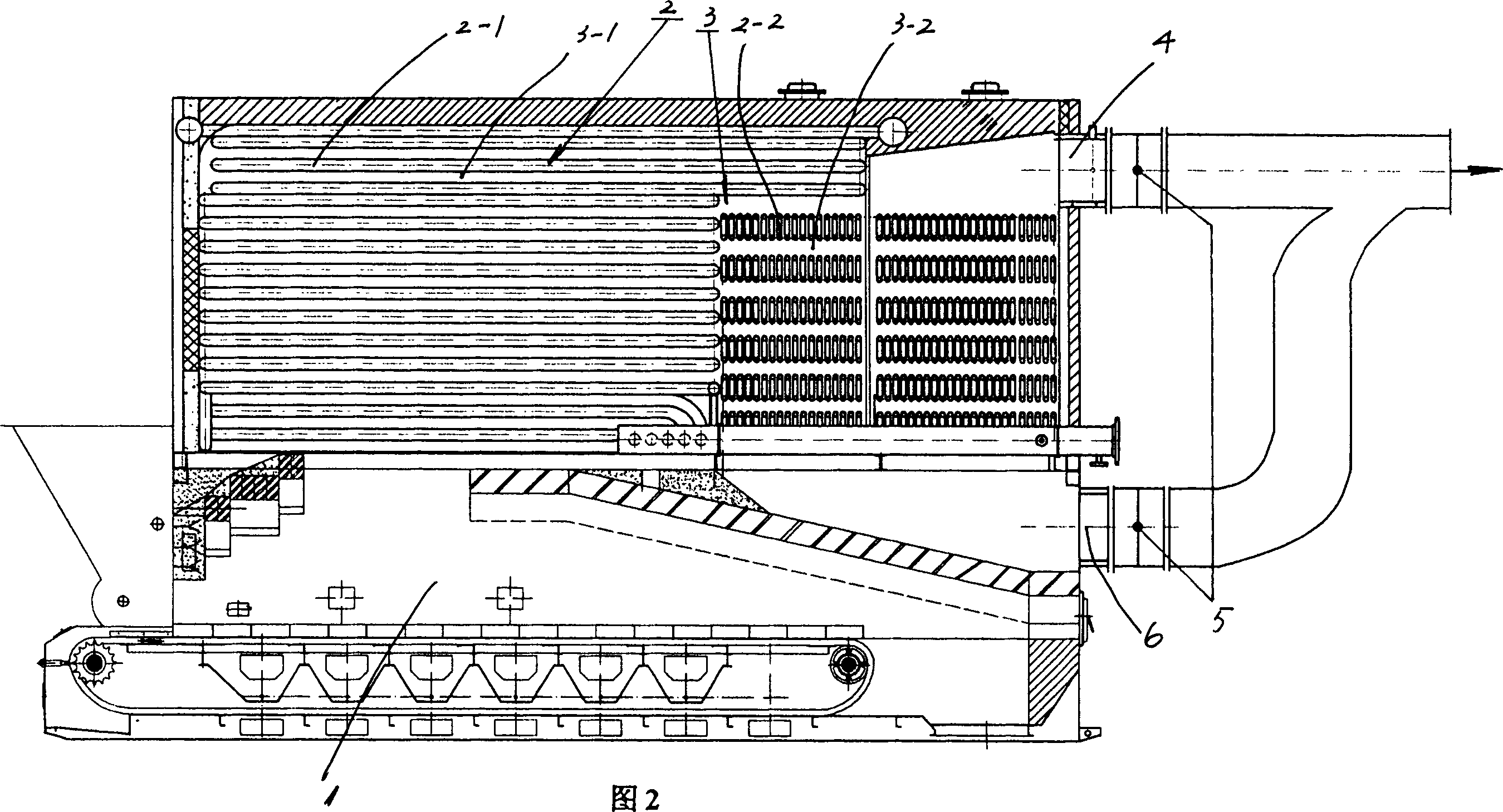

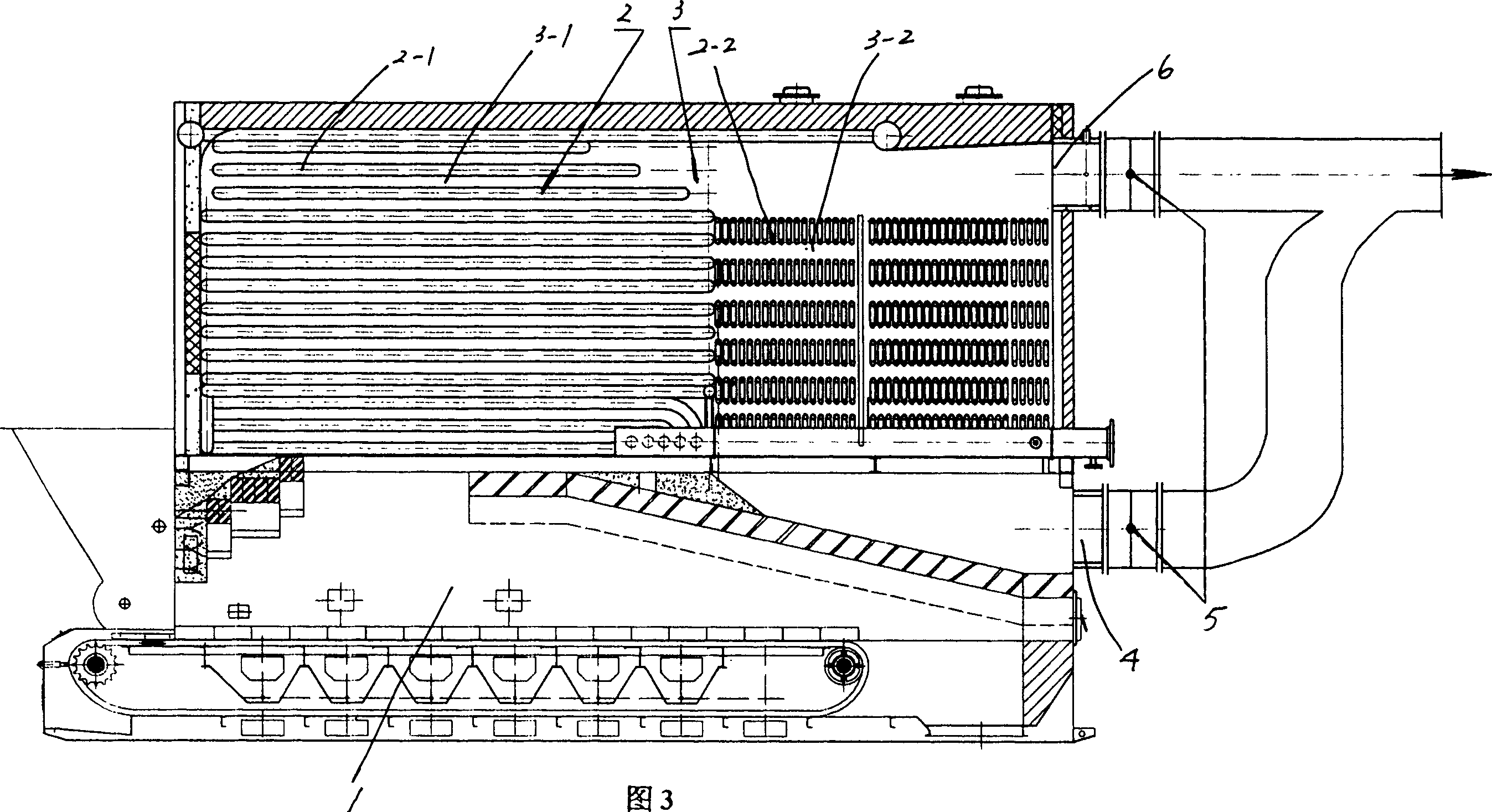

[0024] Through the attached figure 1 Comparing with accompanying drawings 2 and 3, the technical solution of the present invention and its improvements can be understood. The object of the present invention and the technical solution for achieving the object will be more clearly understood by referring to the accompanying drawings in conjunction with the description of specific embodiments.

[0025] Please refer to accompanying drawings 2 and 4 for one of the preferred specific embodiments of the present invention. A solid fuel heat carrier furnace, comprising a solid fuel combustion chamber 1, an entire partition heating surface 2 composed of a partition heating surface 2-1 in a radiation section and a partition heating surface 2-2 in a convection section, and a partition heating surface 2 composed of a partition heating surface 2-2 in a convection section, and the flue gas in the radiation section The entire flue gas channel 3 formed by connecting the channel 3-1 and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com