Group battery composed of single air chamber solid oxide fuel cell

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cell grouping, etc., can solve the problems of increasing the volume and weight of the battery pack, reducing the power density, and unfavorable rapid start of the battery pack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

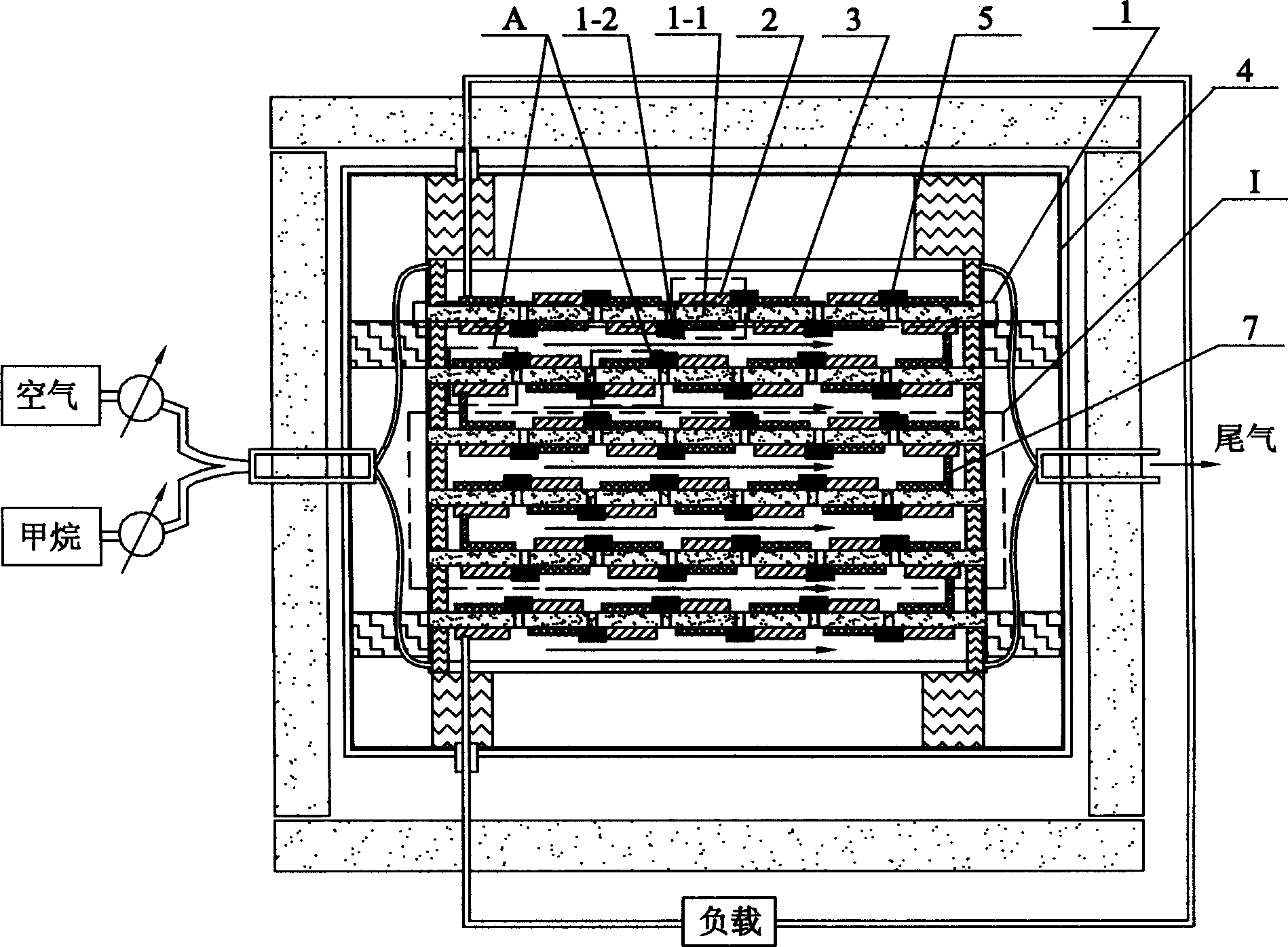

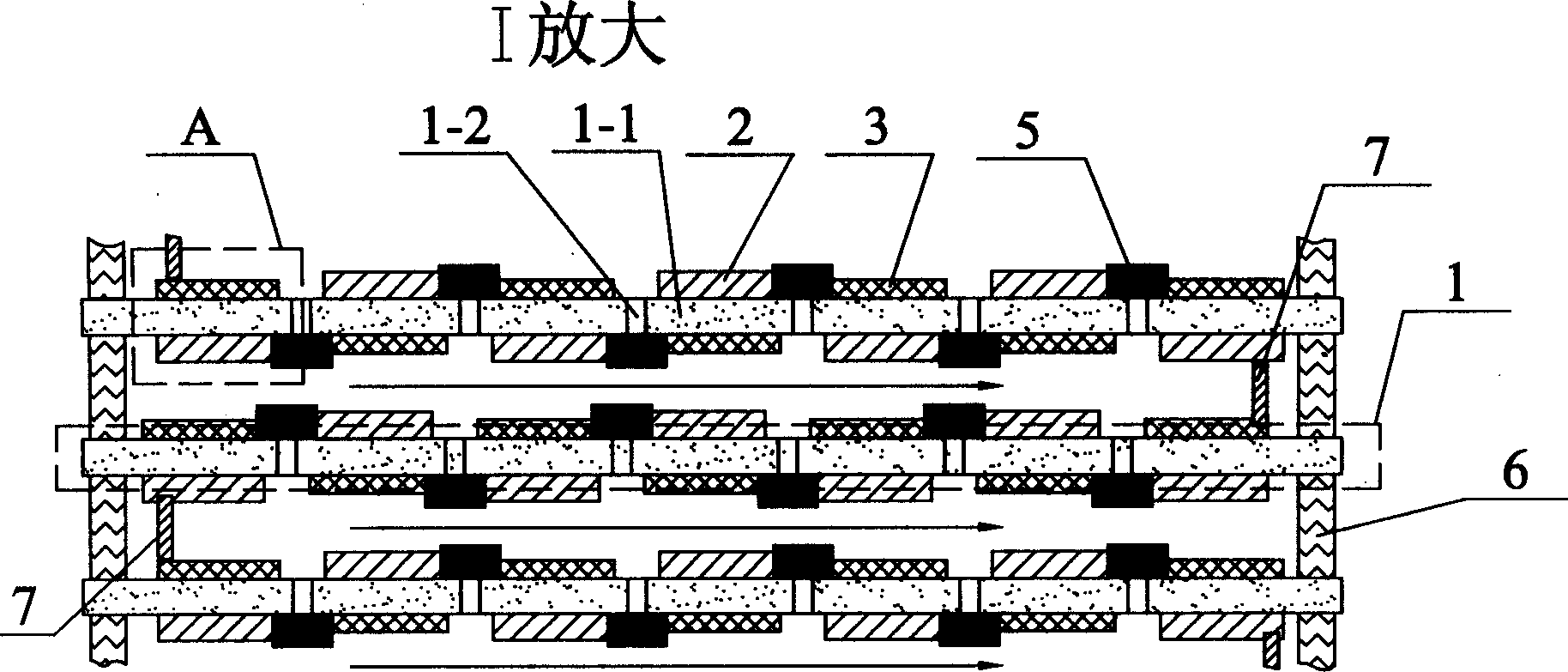

[0005] Specific Embodiment 1: This embodiment includes a group of electrolyte sheets 1 arranged in a container 4, and the two sides of each electrolyte sheet 1 are alternately provided with anodes 2 and cathodes 3, and the polarity of the electrodes on both sides of the same position of the electrolyte sheet 1 On the contrary, a single cell A is formed, and an electrolyte isolation area 1-2 is provided between the electrolytes 1-1 of two adjacent single cells A, and the cathode of the single cell and the anode of the next single cell are connected in series through a conductor, All the electrolyte sheets 1 in the container 4 are connected through wires 7 so that all the single cells A in the container 4 are connected in series, and all the single cells connected in series become a series battery pack.

specific Embodiment approach 2

[0006] Embodiment 2: In this embodiment, each group of electrolyte sheets 1 is arranged parallel to each other. This parallelism does not emphasize absolute parallelism. It only needs to not intersect with each other. It can be parallel to the same direction as the gas flow direction, or It can be parallel to the direction perpendicular to the direction of gas flow, ceramic fibers are set between two adjacent electrolyte sheets 1 as the support body 6, and the connection is realized with high-temperature wires 7, so that a transverse direction can be formed between adjacent electrolyte sheets 1. The flowing gas conveying channel is used to convey the fuel and oxygen mixed reaction gas and tail gas.

specific Embodiment approach 3

[0007] Specific embodiment three: In this embodiment, anodes 2 and cathodes 3 are alternately arranged on both sides of each electrolyte sheet 1, and the raw materials of the anode are transition metal Ni and lanthanide rare earth oxide CeO 2 mixture, the raw material of the cathode is the rare earth transition group composite oxide La 0.7 Sr 0.3 MnO 3 with transition group oxide MnO 2 The raw material of the electrolyte is an oxide solid solution yttria stabilized zirconia with a cubic fluorite structure, and an electrolyte isolation area 1-2 is provided between the electrolytes 1-1 of two adjacent single cells A, and the electrolyte isolation area 1- The formation method of 2 is as follows: first pre-sinter the molded electrolyte sheet 1 at 900-1200°C for 2-6 hours to form a green body with holes, cover the area that needs to be reserved as an electrode, and then cover the area containing La and / Or the saturated solution of Pb nitrate is injected into the predetermined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com