Preparation for composite material with nanometal or metal oxide distributed on surface of carbon nanotube uniformly

A technology of carbon nanotubes and nanometals, which is applied in the field of preparation of composite materials where nanometer metals or metal oxides are evenly distributed on the surface of carbon nanotubes, and can solve the problems of lack of inorganic compounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

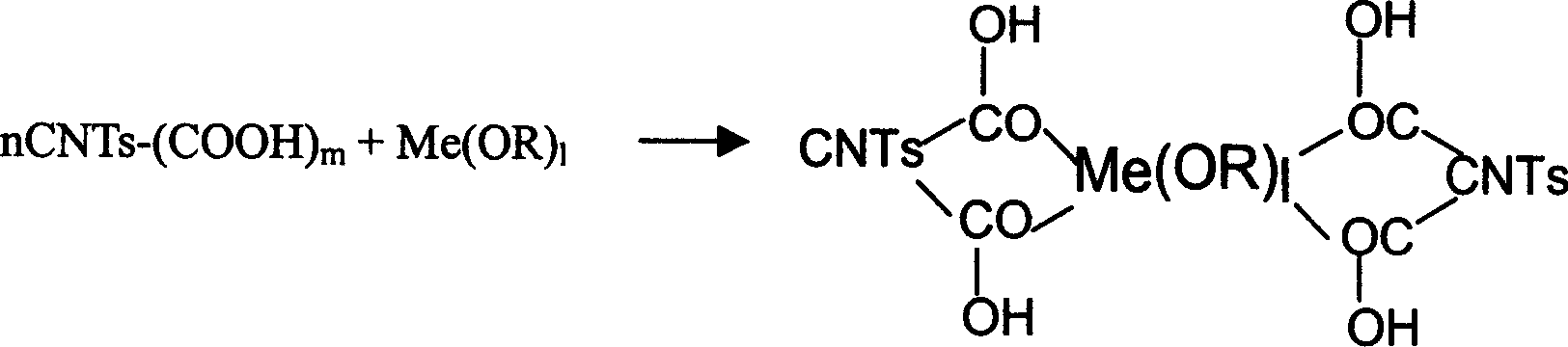

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Add 20 mg of surface-functionalized carbon nanotubes and 1 g of aluminum isopropoxide to 200 mL of isopropanol, heat and ultrasonically disperse for 4 hours, let stand for 12 hours, and then centrifuge the suspension to retain a black solid Substances, put the complexed mixture in an oven to dry. Take 20 mg of the above mixture and put it into 200 mL of diethylene glycol aqueous solution (volume ratio 3:1), react at 95 °C for 2 h, then raise the temperature to 250 °C, and continue the reaction for 8 h to obtain a black product.

[0033] Observation of the resulting Al by high-resolution transmission electron microscopy 2 o 3Composite with carbon nanotubes, it can be seen that there are crystals with irregular shapes of about 10nm on the surface of carbon nanotubes, and the interval between crystals is 500nm, and the distribution is relatively uniform. X-ray diffraction showed Al 2 o 3 properties of crystals.

Embodiment 2

[0034] Example 2: 10 mg of surface-functionalized carbon nanotubes and 300 mg of copper acetate were ultrasonically dispersed in ethanol for 3 h, left to stand for 24 h, and then the suspension was centrifuged, and the precipitate was put into an oven to remove the solvent. The obtained mixture of copper acetate deposited on the surface of carbon nanotubes was put into a closed reactor together with 200 mL of glycerol solvent, and nitrogen gas was introduced. Under vigorous stirring, the temperature was raised to 200 ° C, and the reaction was stopped after 3 hours. The resulting suspension was centrifuged, and the precipitate was washed with distilled water for 3 times, and dried in a vacuum oven to obtain Cu 2 O and carbon nanotube composites.

[0035] The preparation method of metal Cu and carbon nanotube composite material is the same as Cu 2 O is similar to the carbon nanotube composite material, that is, the reaction time is extended to more than 5h, and the temperature ...

Embodiment 3

[0038] Example 3: 300 mg of surface-functionalized carbon nanotubes and 2 g of zinc acetate were ultrasonically dispersed in ethanol for 4 hours, left to stand for 24 hours, and the suspension was directly dried in an oven to remove the solvent. Mix 1 g of the obtained mixture of zinc acetate deposited on the surface of carbon nanotubes with 300 mL of diethylene glycol solvent, heat up to 300 °C under vigorous stirring, and after the hydrolysis reaction lasts for 3 hours, centrifuge and wash, and repeat 3 times, Put it into an oven and dry to obtain a dark gray ZnO and carbon nanotube composite material. The high-resolution transmission electron microscope observation found that in addition to the uniform distribution of ZnO of about 15-40nm on the surface of the carbon nanotubes, there are also some nano-ZnO crystals appearing alone in the background. XRD detection proves that the crystal is ZnO.

[0039] The preparation process of CdO and carbon nanotube composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com