Method for preparing barium-strontium niobate powder and barium-strontium niobate film by organic gel method

A technology of barium strontium niobate and organogel, which is applied in chemical instruments and methods, calcium/strontium/barium compounds, inorganic chemistry, etc., can solve the problems of easy hydrolysis, high price, and difficulty in obtaining metal alkoxides.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0005] Specific embodiment one: this embodiment is prepared according to the following steps: a, preparation of Nb-citric acid complex: Nb 2 o 5 Dissolve in HF at 70-90°C, then add ammonium oxalate solution to it, after mixing thoroughly, add ammonia water to the solution to form white Nb(OH) 5 Precipitate, which is aged at 70-90°C for 10-14 hours, filtered and washed, dissolved in citric acid aqueous solution to form a light yellow Nb-citric acid solution; b, water-soluble Ba-EDTA and Preparation of Sr-EDTA complex: equimolar Ba(NO 3 ) 2 and EDTA were dissolved in deionized water, and the pH was adjusted to be alkaline with ammonia water to obtain a transparent Ba-EDTA solution, and finally HNO 3 Adjust pH=7, prepare Sr-EDTA solution in the same way; c, preparation of barium strontium niobate nanopowder: measure Sr-EDTA, Ba-EDTA and Nb-citric acid solution respectively, control molar ratio as Sr 2+ : Ba 2+ : Nb 5+ =x: (1-x): 2, wherein x=0~1, add citric acid after the t...

specific Embodiment approach 2

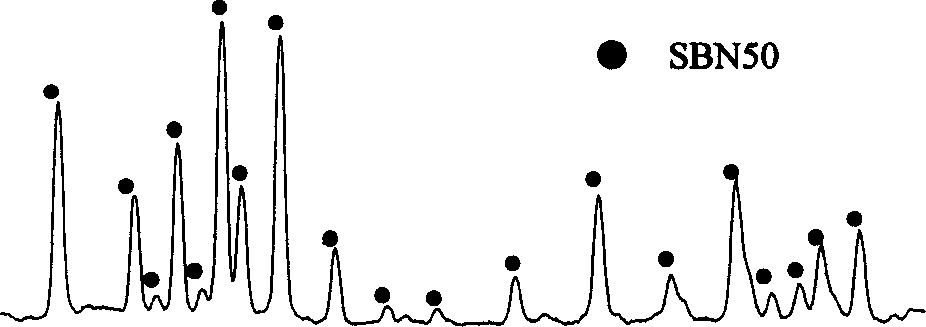

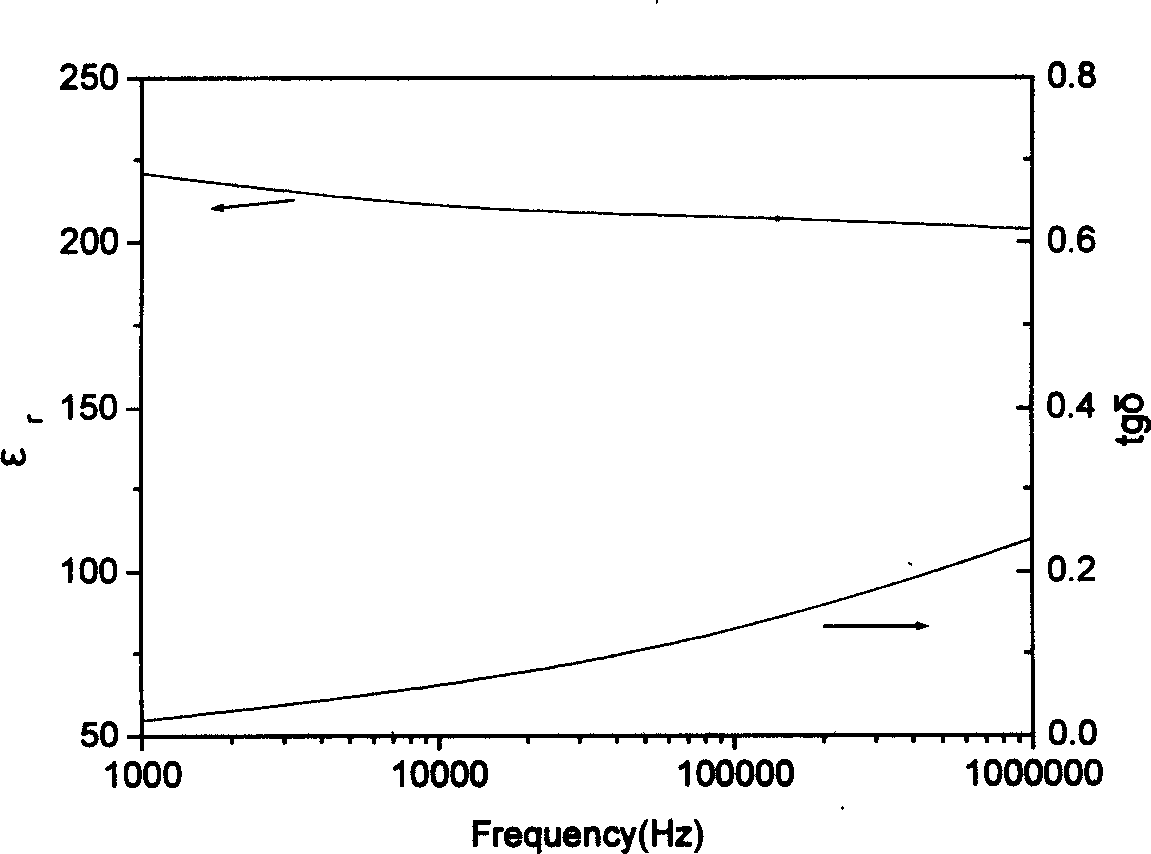

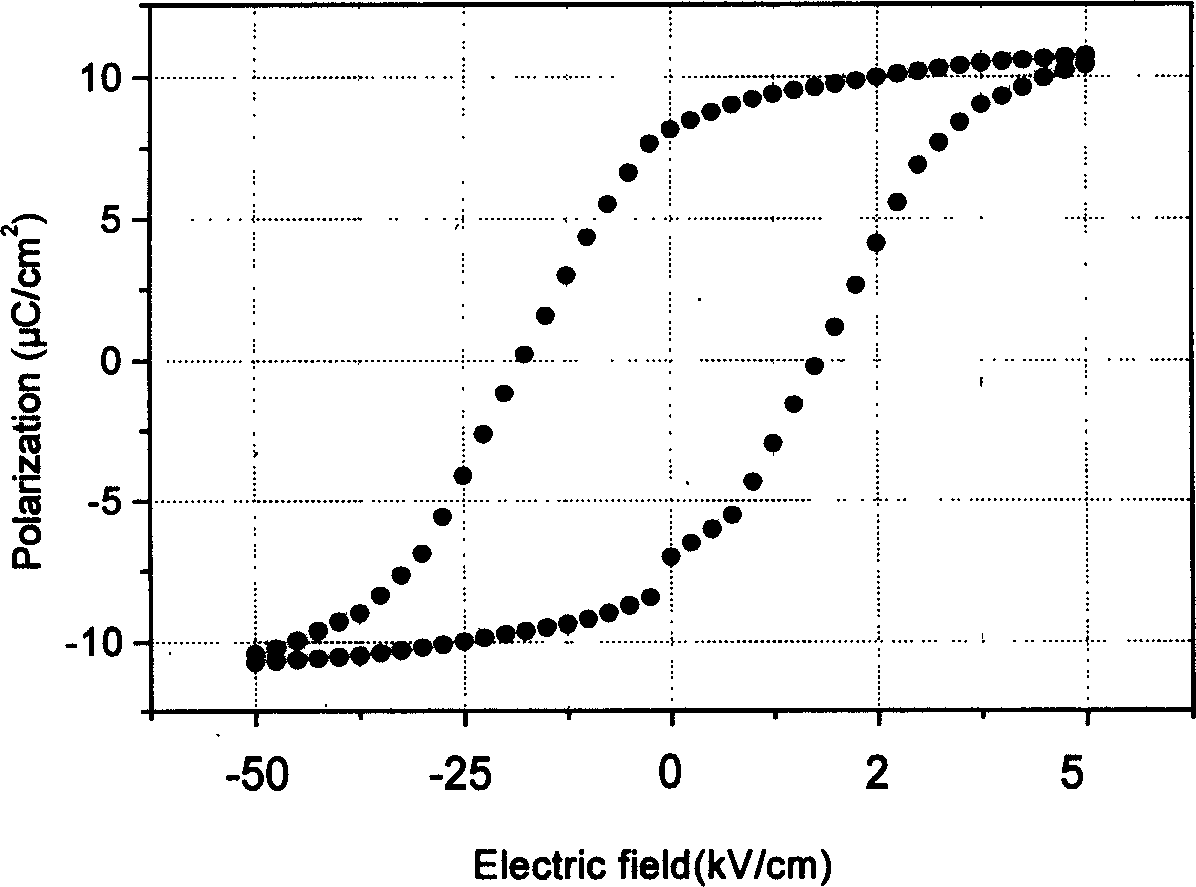

[0006] Specific implementation mode two: see figure 1 , this embodiment is prepared according to the following steps: a, 0.1molNb 2 o 5 Add it into 1.4mol of HF, heat in a water bath at 80°C for 48-50h, and keep stirring to make Nb 2 o 5 Dissolved in HF to form NbOF 5 2- or NbF 7 2- complex ion; then add the newly prepared ammonium oxalate aqueous solution, and keep C 2 o 4 2- Ion excess; add ammonia dropwise to solution to form white Nb(OH) 5 precipitate, the precipitate was aged at 80 °C for 12 h, filtered, and washed with 5 wt% ammonia to remove F - ion; finally the Nb(OH) 5 Precipitation is dissolved in the citric acid aqueous solution, forms light yellow Nb-citric acid solution, adopts inductively coupled plasma emission spectrometry (ICP) to measure the concentration of metal ion; b, 0.1molBa (NO 3 ) 2 After mixing with 0.1mol EDTA, add deionized water, adjust the pH with ammonia water to make it alkaline, and keep stirring to obtain a transparent Ba-EDTA so...

specific Embodiment approach 3

[0007] Specific embodiment three: this embodiment is prepared according to the following steps: a, preparation of Nb-citric acid complex: Nb 2 o 5 Dissolve in HF at 70-90°C, then add ammonium oxalate solution to it, after mixing thoroughly, add ammonia water to the solution to form white Nb(OH) 5 Precipitate, which is aged at 70-90°C for 10-14 hours, filtered and washed, dissolved in citric acid aqueous solution to form a light yellow Nb-citric acid solution; b, water-soluble Ba-EDTA and Preparation of Sr-EDTA complex: equimolar Ba(NO 3 ) 2 and EDTA were dissolved in deionized water, and the pH was adjusted to be alkaline with ammonia water to obtain a transparent Ba-EDTA solution, and finally HNO 3 Adjust pH=7, prepare Sr-EDTA solution in the same way; c, the preparation of SBN film: Measure Sr-EDTA, Ba-EDTA and Nb-citric acid solution respectively, control molar ratio as Sr 2+ : Ba 2+ : Nb 5+ =x: (1-x): 2, wherein x=0~1, after mixing the three solutions evenly, add cit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com