Water intake pipes emptying and antifreeze method and apparatus

An anti-freezing device and water pipe technology, applied in heating devices, solar thermal devices, solar thermal power generation and other directions, can solve the problems of high usage fee, increase usage fee, can not prevent freezing cracks, etc., achieve low cost and reduce installation cost , The effect of reducing corrosion time and water pressure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

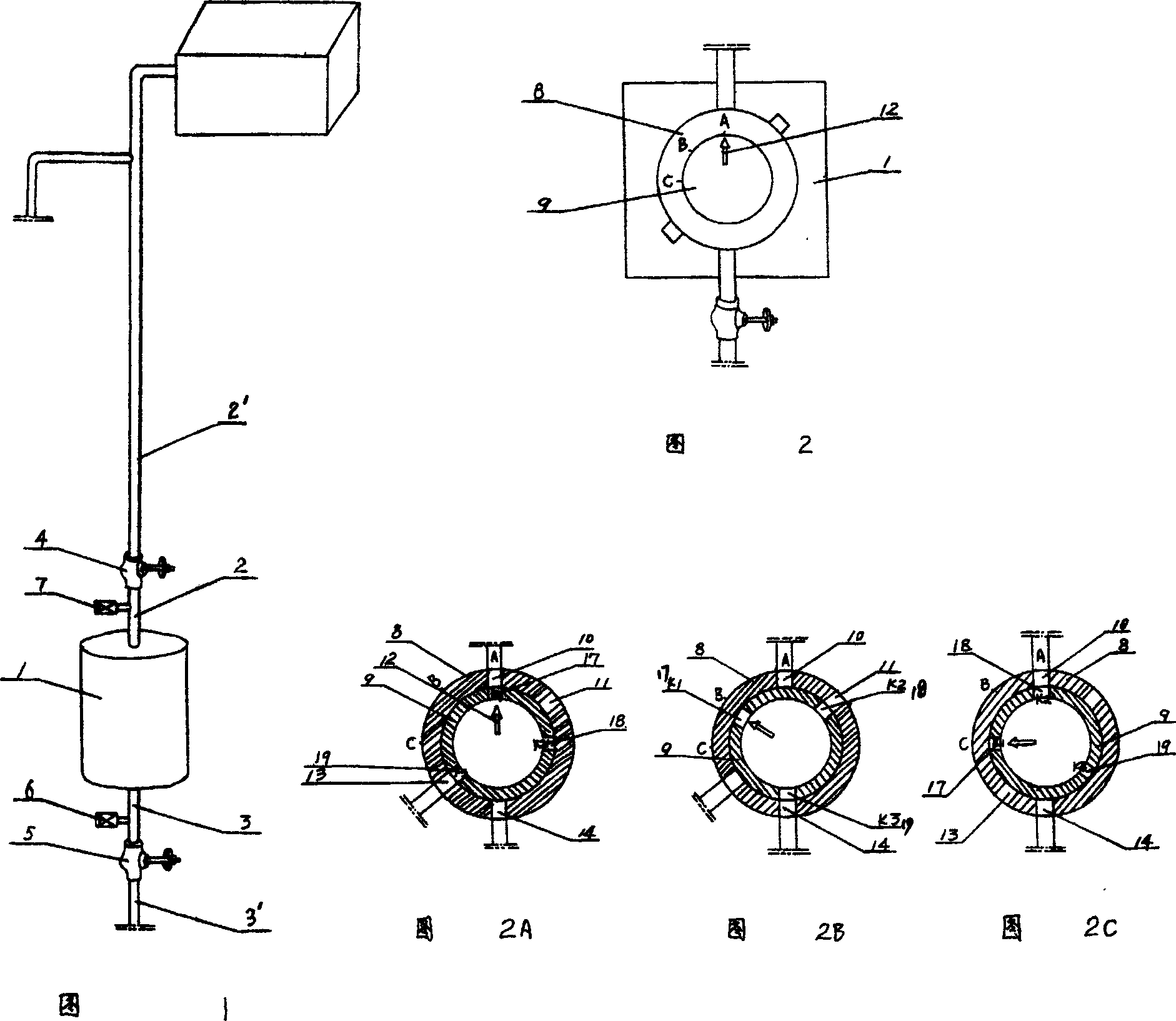

[0016] Embodiment 1 is made with reference to FIG. 1 . An upper water pipe emptying device is characterized in that the device is composed of a box body 1, an upper water pipe joint 2 on the upper side of the box body 1, and an upper water pipe joint 3 on the lower side of the box body 1, and the upper water pipe joint on the upper side of the box body 1 The joint 2 is provided with an air-water exchange switch 4 and an air intake valve 7, and a cut-off switch 5 and a drain valve 6 are arranged on the upper water pipe joint 3 on the lower side of the box body 1. When in use, the upper water pipe joint on the upper side of the box body 1 2. Connect with the lower port of the upper water pipe 2' on the upper side of the box body 1, the upper water pipe joint 3 on the lower side of the box body 1 is connected with the tap water pipe 3' or the water inlet equipment, and the outer nozzle of the drain valve 6 is connected with the drain pipe to drain water. The pipe is externally co...

Embodiment 2

[0018] Referring to Figure 2, Figure 2A, Figure 2B, and Figure 2C, Example 2 is produced. Figure 2 shows an embodiment of integrating valves or switches on the device. The anti-freezing device for emptying the upper water pipe is composed of a rotating core shell 8, a rotating core 9 and a box body 1. The box body 1 is fixed on one end of the rotating core shell 8, and the rotating core 9 is installed in the rotating core shell 8 and tightly fitted. , will not produce water leakage, can be made of ceramic materials or plastics, four through holes are arranged along the same cross section on the rotating core shell 8, and the one on the upper side is the upper water pipe through hole 10, which is rotated 45 degrees clockwise The air intake through hole 11 is set everywhere, the one on the lower side is a drainage through hole 14, and the clockwise rotation of 225 degrees is a water pipe through hole 13, and the rotating core 9 is provided with three through holes, which are conne...

Embodiment 3

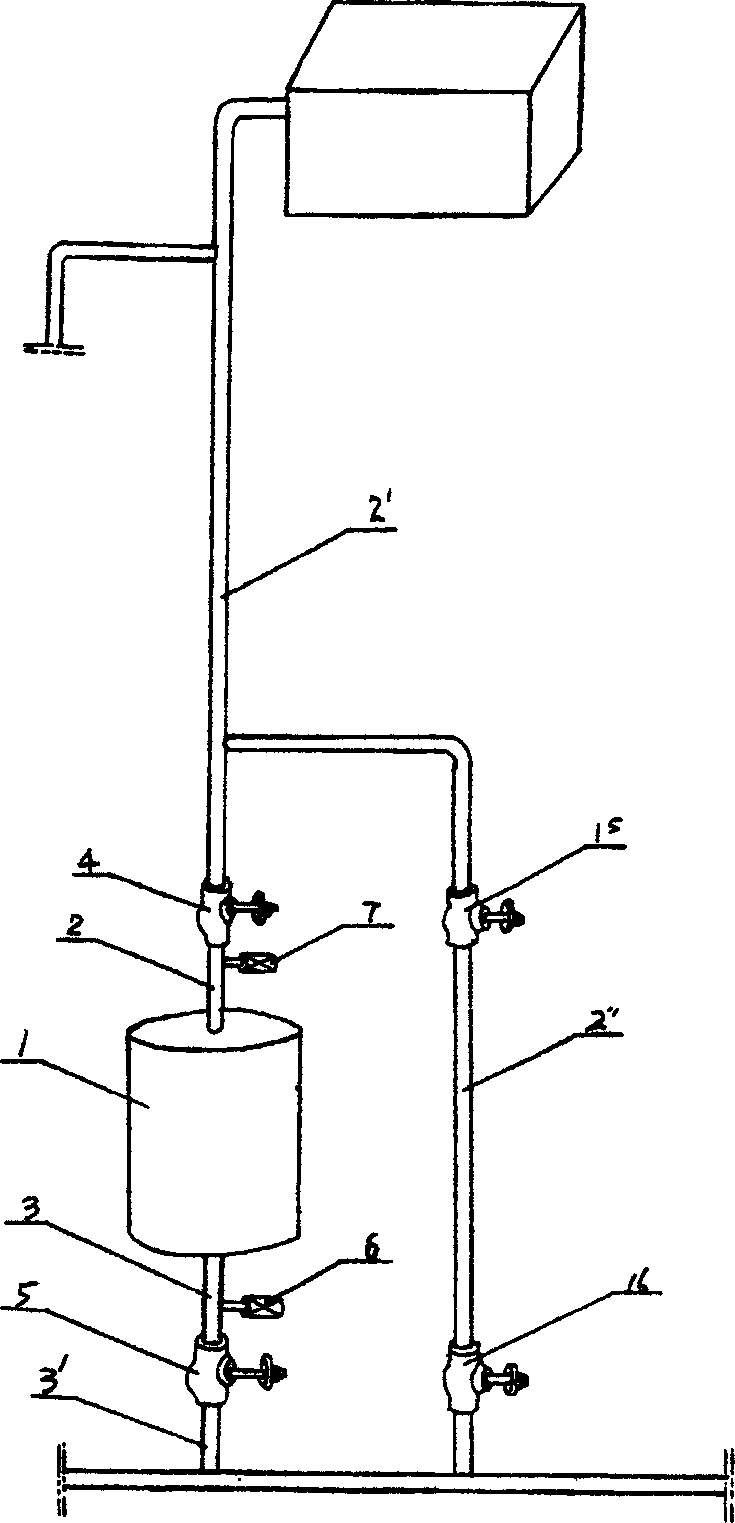

[0020] refer to image 3 Production Example 3. The described upper water pipe emptying antifreeze device can also be adopted as image 3 The shown parallel mode is connected to one side of the main pipeline 2 "of the upper water pipe 2'. The structure of the device is shown in Figure 1. In this connection method, two valves 15, 16 need to be established on the main pipeline 2".

[0021] The upper water pipe 2' may include a vertical upper water pipe and an inclined upper water pipe. During installation, care should be taken that the upper water pipe in the inclined section must not have a large bend.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com