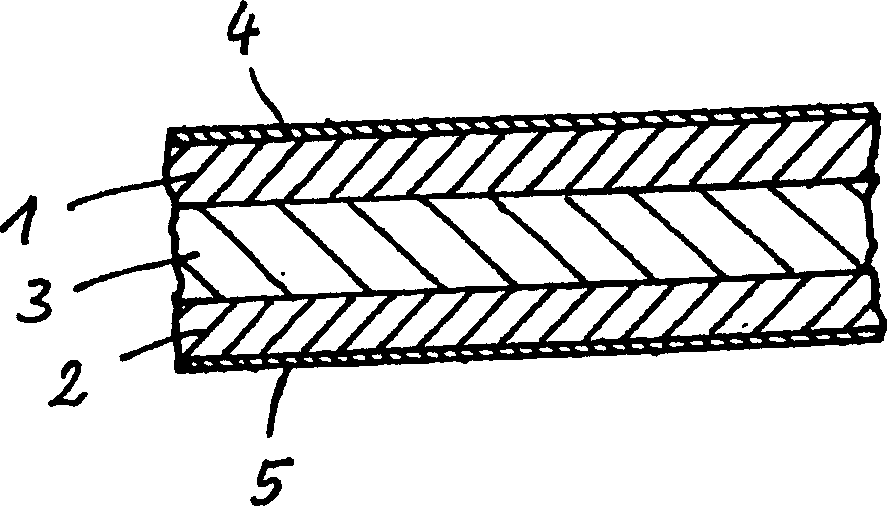

Elastomer-bonded sheet material and process for its production

A technology for elastomers, vulcanized elastomers, used in chemical instruments and methods, other chemical processes, other household appliances, etc., and can solve problems such as material hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Composition 1 with sole R rubber as matrix

[0023] A homogeneous mass of vulcanizate powder was prepared by mixing the following raw materials in a tubular mixer.

[0024] 13-17 parts of R rubber, which is nitrile rubber at this time

[0025] 38-45 parts kaolin

[0026] 3-8 parts of precipitated silica

[0027] 5-9 parts of para-aramid fiber

[0028] 25-30 parts glass fiber

[0029] 2 to 3 parts of sulfur-based vulcanization additives, including sulfur, accelerators, activators, co-activators and processing aids.

[0030] During mixing, 28-33 parts (based on total dry matter) of toluene were used to dissolve the NBR.

Embodiment 2

[0031] Example 2: Composition 2 with a blend of R and M rubbers or a partially hydrogenated R rubber as a matrix

[0032] A homogeneous mass of vulcanizate powder was prepared by mixing the following raw materials in a tubular mixer.

[0033] 6.8 to 8.5 parts of R rubber; nitrile rubber

[0034] 6.8-8.5 parts of M rubber or rubber with double bond content <7%, which is partially hydrogenated nitrile rubber (34±1% ACN, residual double bond 3-5%)

[0035] 38-45 parts kaolin

[0036] 3-8 parts of precipitated silica

[0037] 5-9 parts of para-aramid fiber

[0038] 25-30 parts glass fiber

[0039] 2 to 3 parts of sulfur-based vulcanization additives, including sulfur, accelerators, activators, co-activators and processing aids.

[0040] During mixing, 28-33 parts (based on total dry matter) of toluene were used to dissolve the two elastomers.

Embodiment 3

[0041] Example 3: Composition 3 with sole M rubber or partially hydrogenated R rubber as matrix

[0042] A homogeneous mass of vulcanizate powder was prepared by mixing the following raw materials in a tubular mixer.

[0043] 13-17 parts of M rubber or rubber with double bond content <7%, which is partially hydrogenated nitrile rubber (34±1% ACN, residual double bond 3-5%)

[0044] 38-45 parts kaolin

[0045] 3-8 parts of precipitated silica

[0046] 5-9 parts of para-aramid fiber

[0047] 25-30 parts glass fiber

[0048] 2 to 3 parts of sulfur-based vulcanization additives, including sulfur, accelerators, activators, co-activators and processing aids. During mixing, 28-33 parts (based on total dry matter) of toluene were used to dissolve the HNBR.

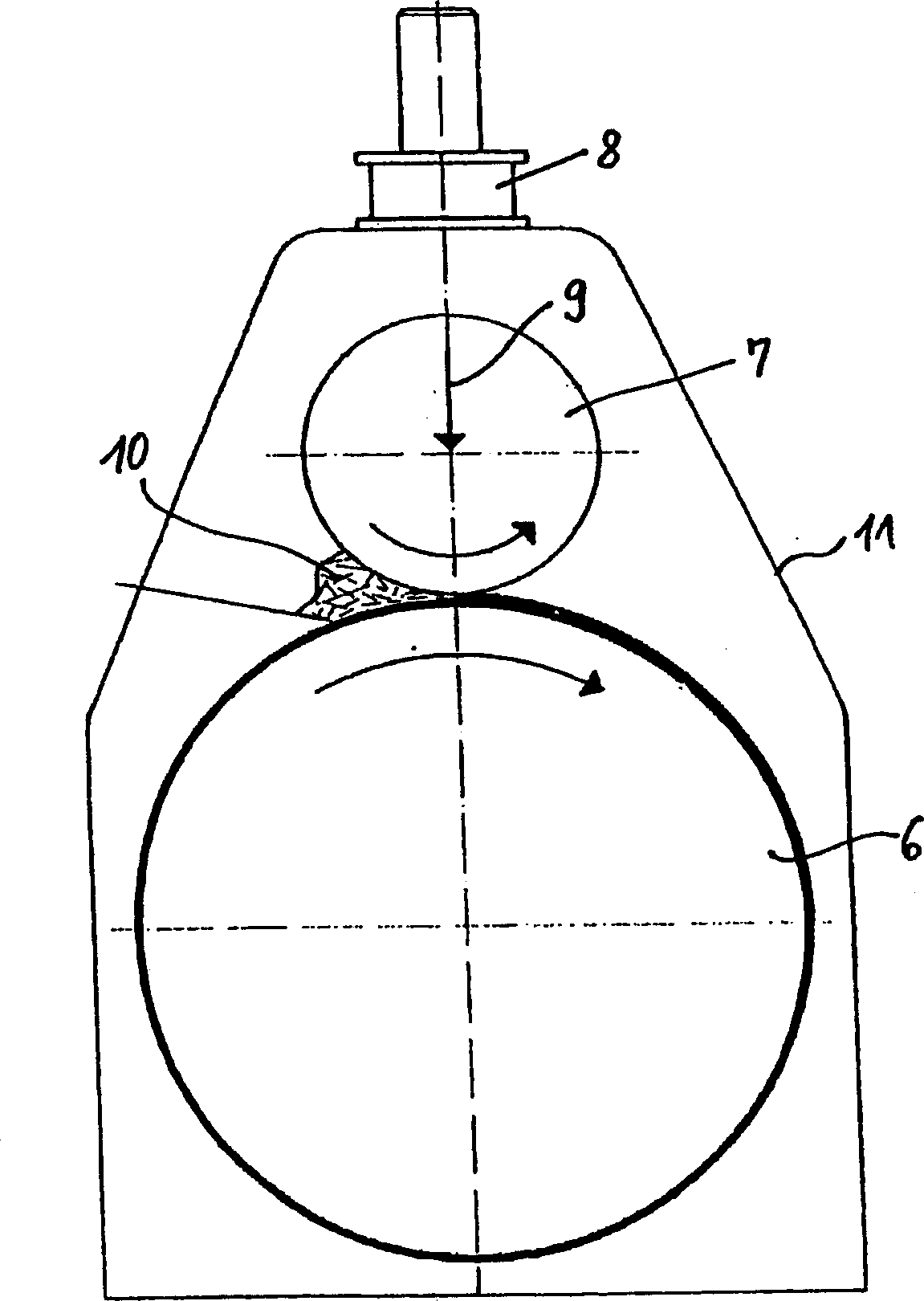

[0049] Example of manufacturing sample sheet

[0050] use figure 2 A two-roll vertical calender was used to fabricate sample sheets.

[0051] Use high-pressure water to heat the surface temperature of the roller 6 to 180±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com