Waste gas processing system

A waste gas treatment and waste gas technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inability to completely remove sulfur trioxide, inability to fully adsorb and remove coal dust, and increase equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

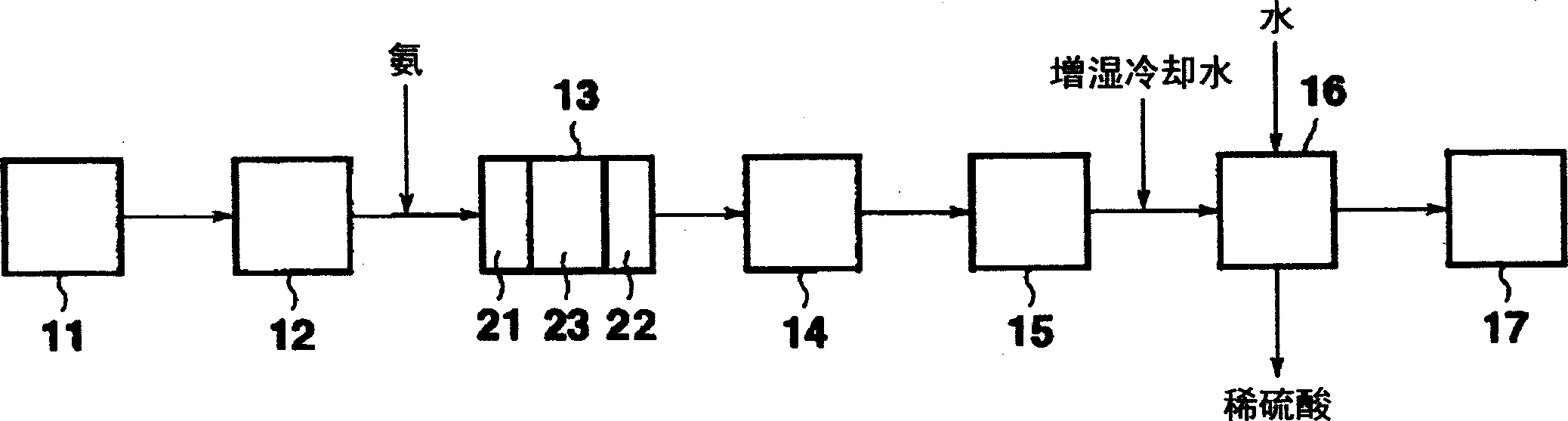

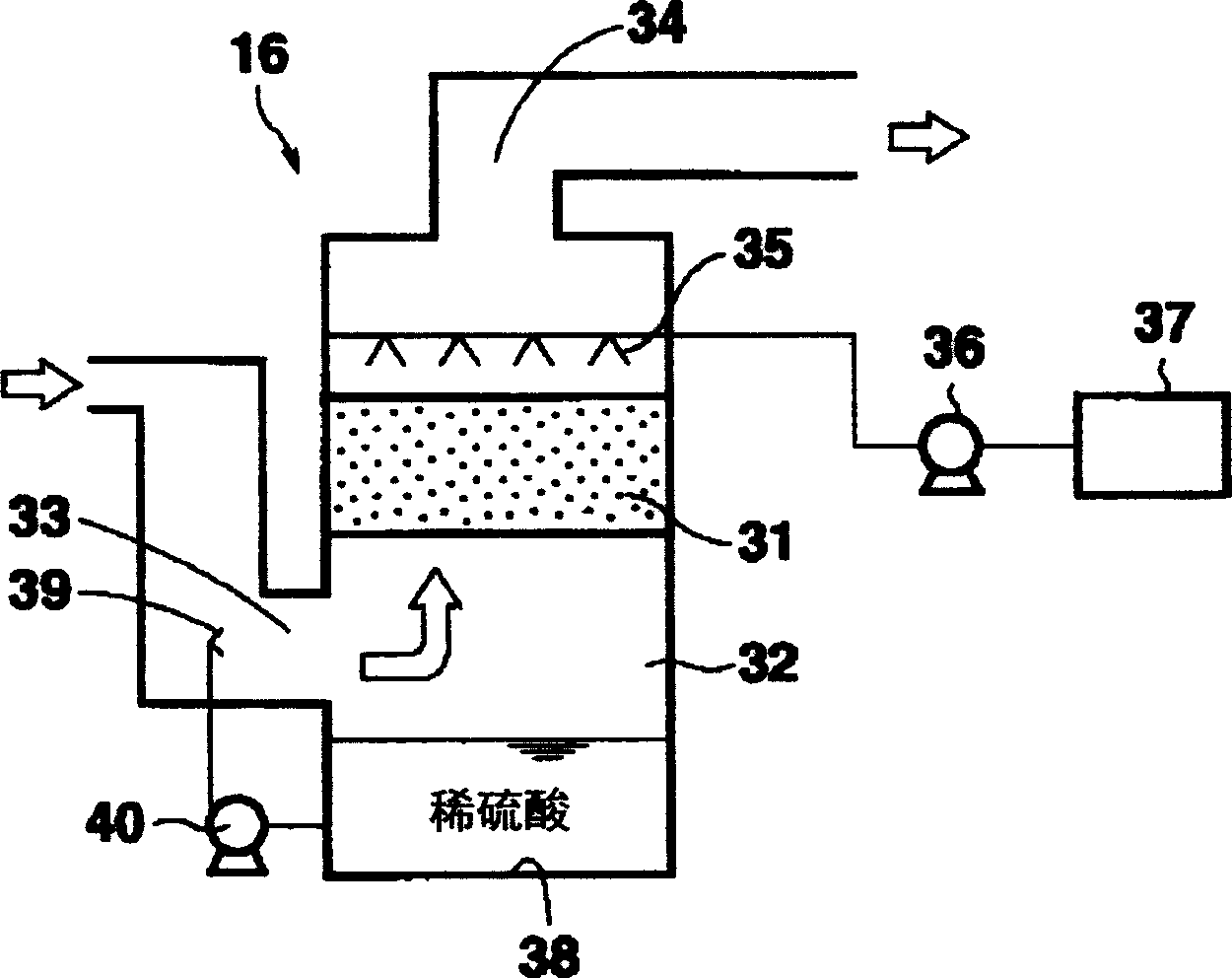

[0019] exist figure 1 A schematic configuration of an exhaust gas treatment system according to an embodiment of the present invention is shown in figure 2 The schematic configuration of the ACF desulfurization unit is shown in .

[0020] The exhaust gas treatment system of this embodiment is used in boiler facilities (burning furnaces, incinerators) using fuels containing high sulfur components such as petroleum coke and Ori-mulsion.

[0021] Such as figure 1 As shown, the waste gas treatment system of this embodiment is that for the waste gas discharged from the boiler 11, a high-temperature dry electric dust collector 12, a denitrification device 13, an air heater 14, an exhaust fan 15, an ACF desulfurization device 16, and a chimney are continuously arranged. 17 and constituted.

[0022] The exhaust gas of about 200-400 degreeC is supplied from the boiler 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com