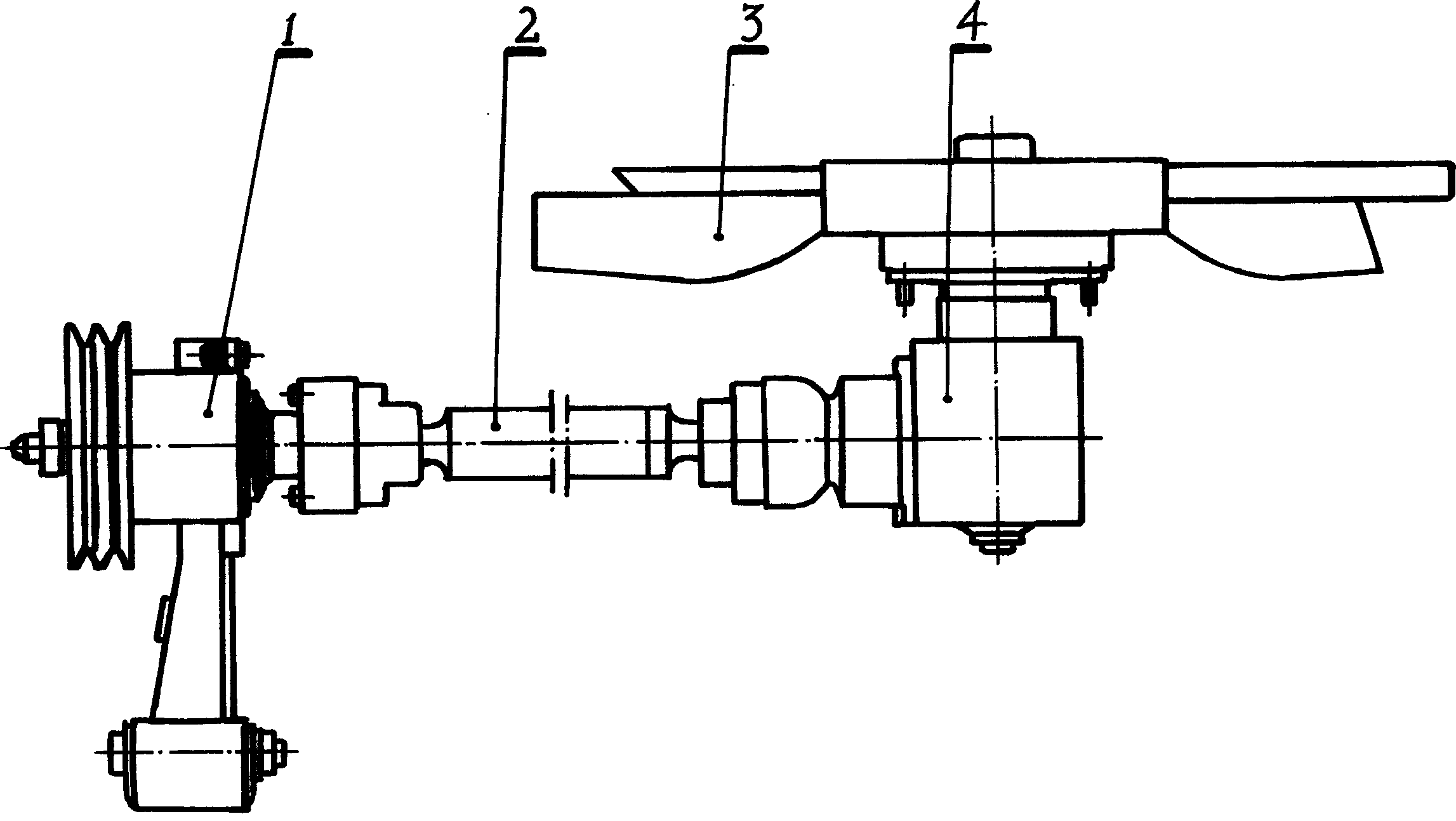

Automobile cooling-fan driving mechanism assembly

A driving mechanism and automobile cooling technology, which is applied to the cooling of engine components, machines/engines, and engines, can solve the problems of unstable operating temperature of the engine, large noise and exhaust pollutants, and increased engine volume, so as to achieve sufficient Adaptability options, reduction of noise and exhaust pollutants, and the effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

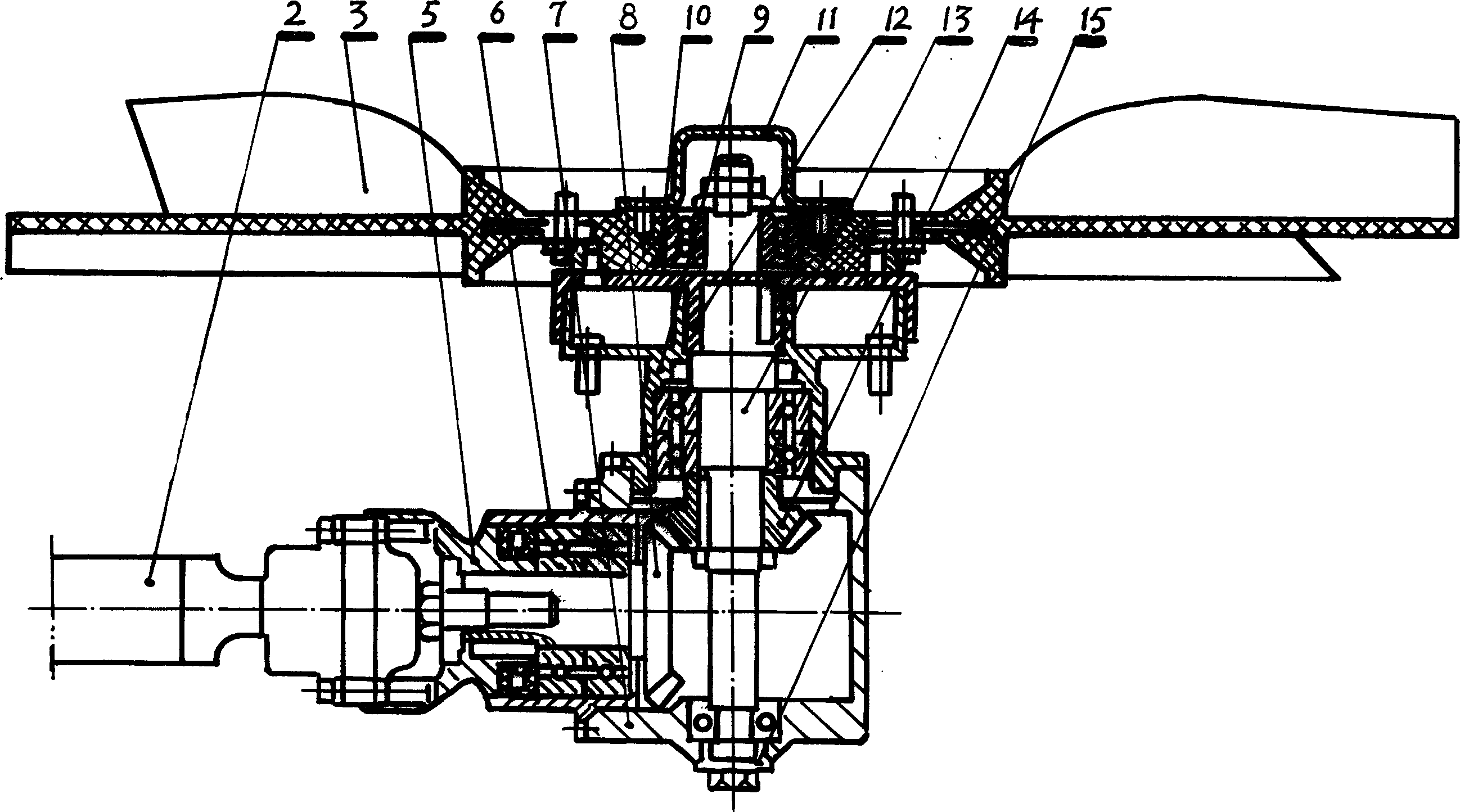

Embodiment 1

[0015] The first embodiment does not install the magnetic clutch 21, and is an economical fan drive mechanism assembly. The large bevel gear 8 and the small bevel gear 14 have undergone high-precision machining and strict heat treatment, and splash lubrication is carried out when the gears rotate to ensure effective heat dissipation and reduce noise of the gear pair. The transmission shaft assembly 2 adopts a telescopic ball cage universal joint, which has a simple and concise structure, small sliding resistance and high transmission efficiency. The mechanism assembly can adopt a fan with a large diameter of 560-720mm, which is very convenient for installation and debugging.

Embodiment 2

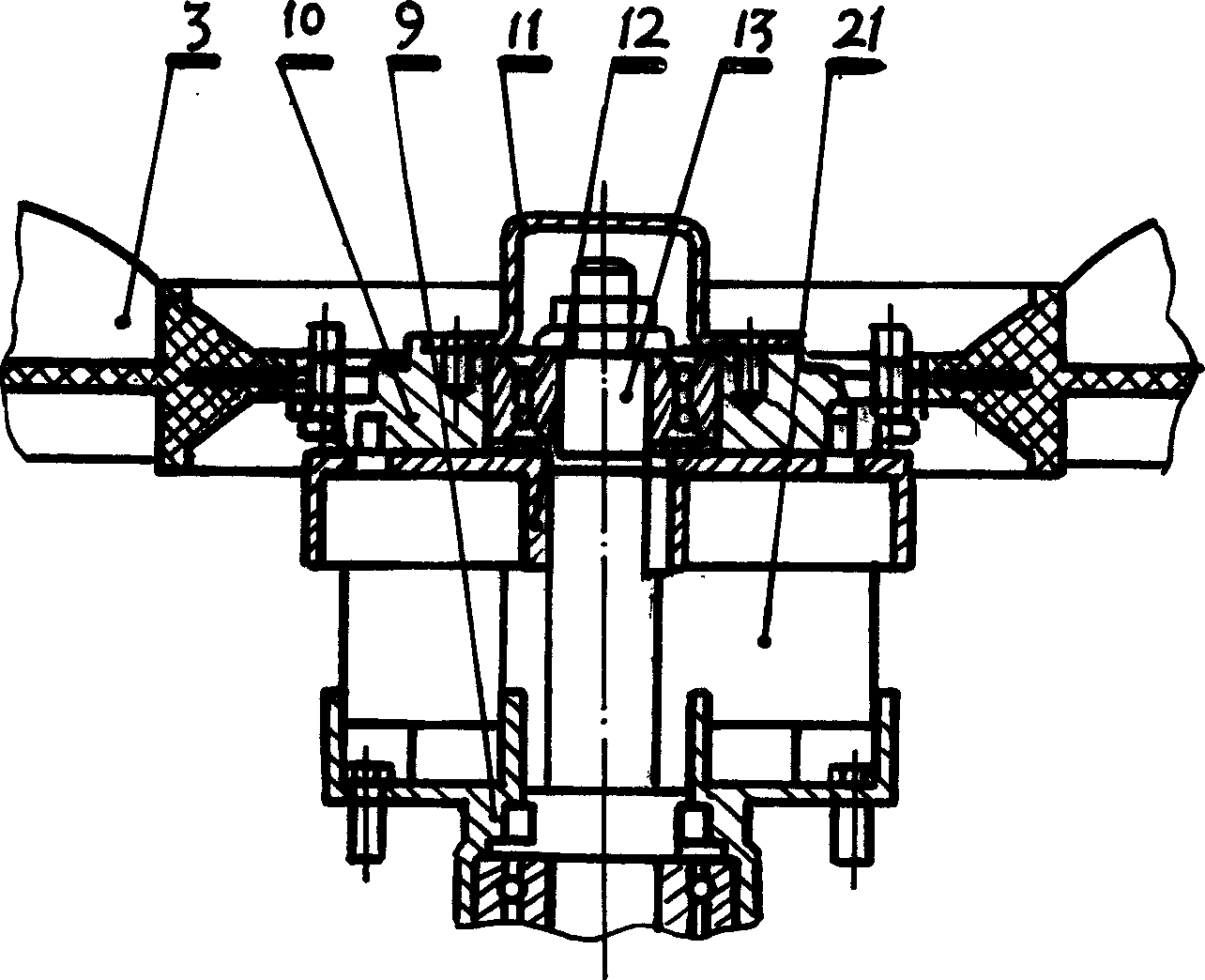

[0016] Embodiment 2 is equipped with a magnetic clutch 21, which is a luxurious fan drive mechanism assembly. The magnetic clutch 21 works under the condition of no torsional force and drag torque. Through the temperature sensor in the cooling circuit, the rotation direction of the fan can be changed accurately and quickly, which has a very high efficiency and makes the fan have good adaptability, thus effectively reducing fuel consumption and reducing noise.

[0017] The Magnetic Clutch 21 is available in three different sizes:

[0018] Level 1 speed magnetic clutch 21: With the breaking torque of the magnetic clutch 21, it acts through bearing friction, and the fan rotates at a speed of 100 revolutions per minute.

[0019] 2-stage speed magnetic clutch 21: With the torque off of the magnetic clutch 21, the fan blades rotate at a speed of 1200 revolutions per minute driven by the permanent magnet system without contact and friction.

[0020] 3-speed magnetic clutch 21: With...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com