Industrial continuous powder frequency steam vibrative screening mill

A vibratory screening, industrial technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of high frequency, low noise, small amplitude, etc., to achieve broad application prospects, reduce costs, reduce audio noise pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

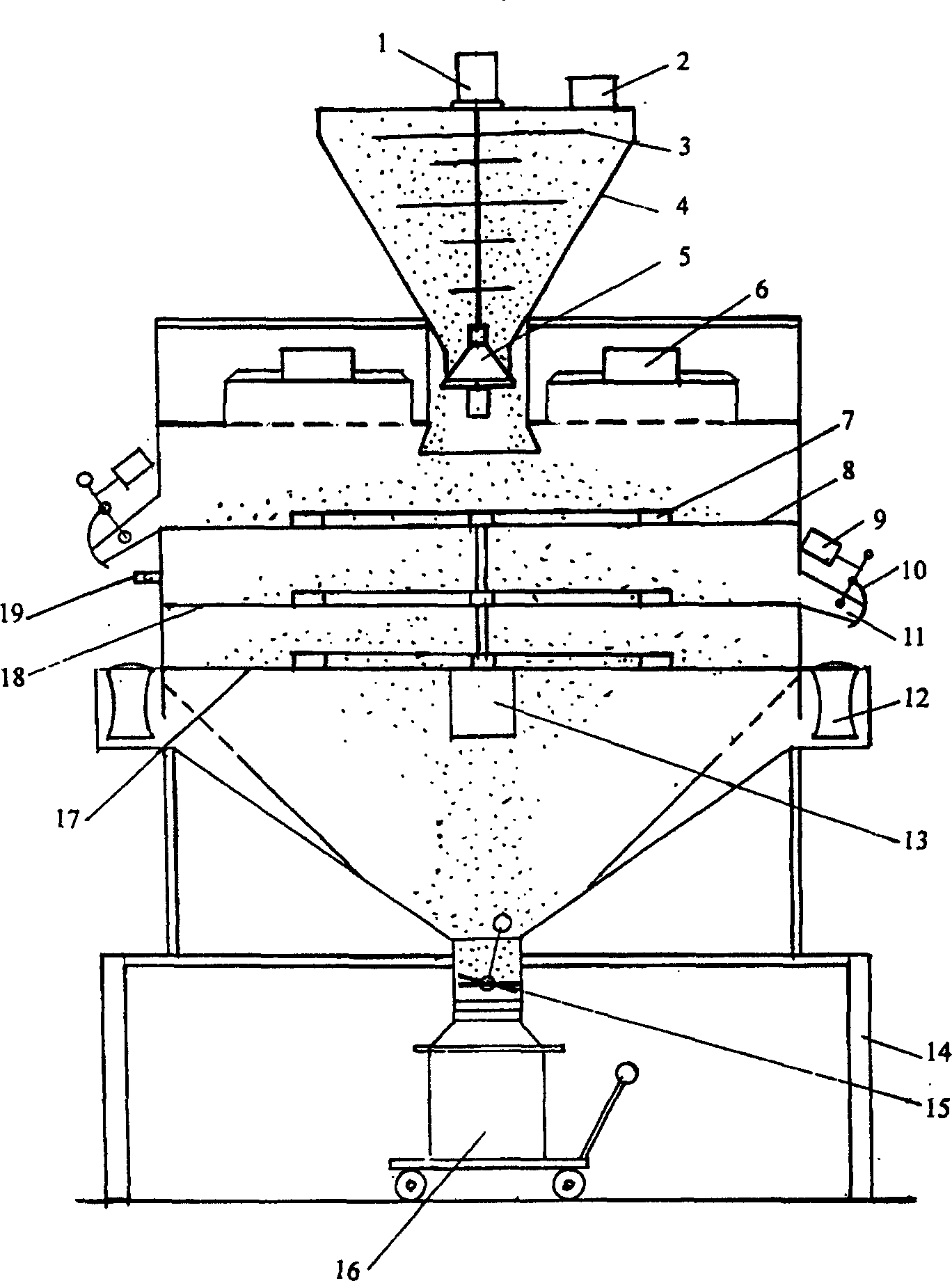

[0020] Embodiment 1 and effect see figure 1 :

[0021] The power frequency airflow vibrating screen for preparing φ600mm three-layer screen should be designed according to the following

[0022] 1. Preparation of screen frame cylinder

[0023] a. First prepare a stainless steel fully enclosed cylinder with an inner diameter of φ600mm and a height of 500mm, cut into four sections of equal height, connect them with flanges and seal them with "O"-shaped sealing rings to prevent air leakage at the joints of each section.

[0024] b.at figure 1 The coarse powder discharge pipe 11 of each layer, the upper feed bin 4 and the discharge pipe and sleeve pipe of the bottom are welded on the position shown.

[0025] c. The outer ring of the resonance capsule at the lower part of the welding cylinder and the lower double-layer funnel slant plate, the feeding tube of the feeding car cylinder, the welding cylinder bracket 14 and N 2 , Ar gas inlet valve 19.

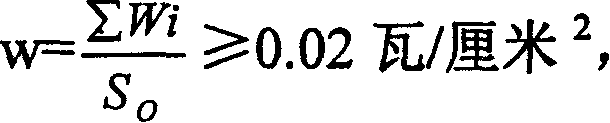

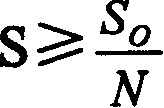

[0026] 2. Design the power ...

Embodiment 2

[0036] The first and second layers of screen cloth in the embodiment equipment are removed, but the third layer of screen cloth adopts 500 mesh, that is, the screen cloth with a screen aperture of 25.4 μm, and then an ultrafine carbon black with an average particle diameter of 3.5 μm powder, to carry out a comparison test of screening efficiency. The comparison screening device is a company's product - a mechanical vibration sieving instrument. The comparison condition is to weigh 300 grams of ultra-fine carbon black powder each, and the use area of the two screens is 300 cm 2 , the unused sieve area is all closed with plastic tape, and the sieving time is 10, 20, 30, 60, 120, 1800 minutes, and the weight of the powder under the sieve is weighed respectively. The results are shown in Table 2

[0037] Table 2 Comparison of screening efficiency of carbon black powder

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com