Joint-telescopic type super high voltage live cleaning robot

A live cleaning and telescopic technology, which is applied to the installation of manipulators, electrical components, and cables, can solve the problems of many joints in the scissor lift mechanism, affecting the positioning of the cleaning arm, and difficult processing and assembly, so as to avoid inconvenience and economic loss. , high degree of automation, convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

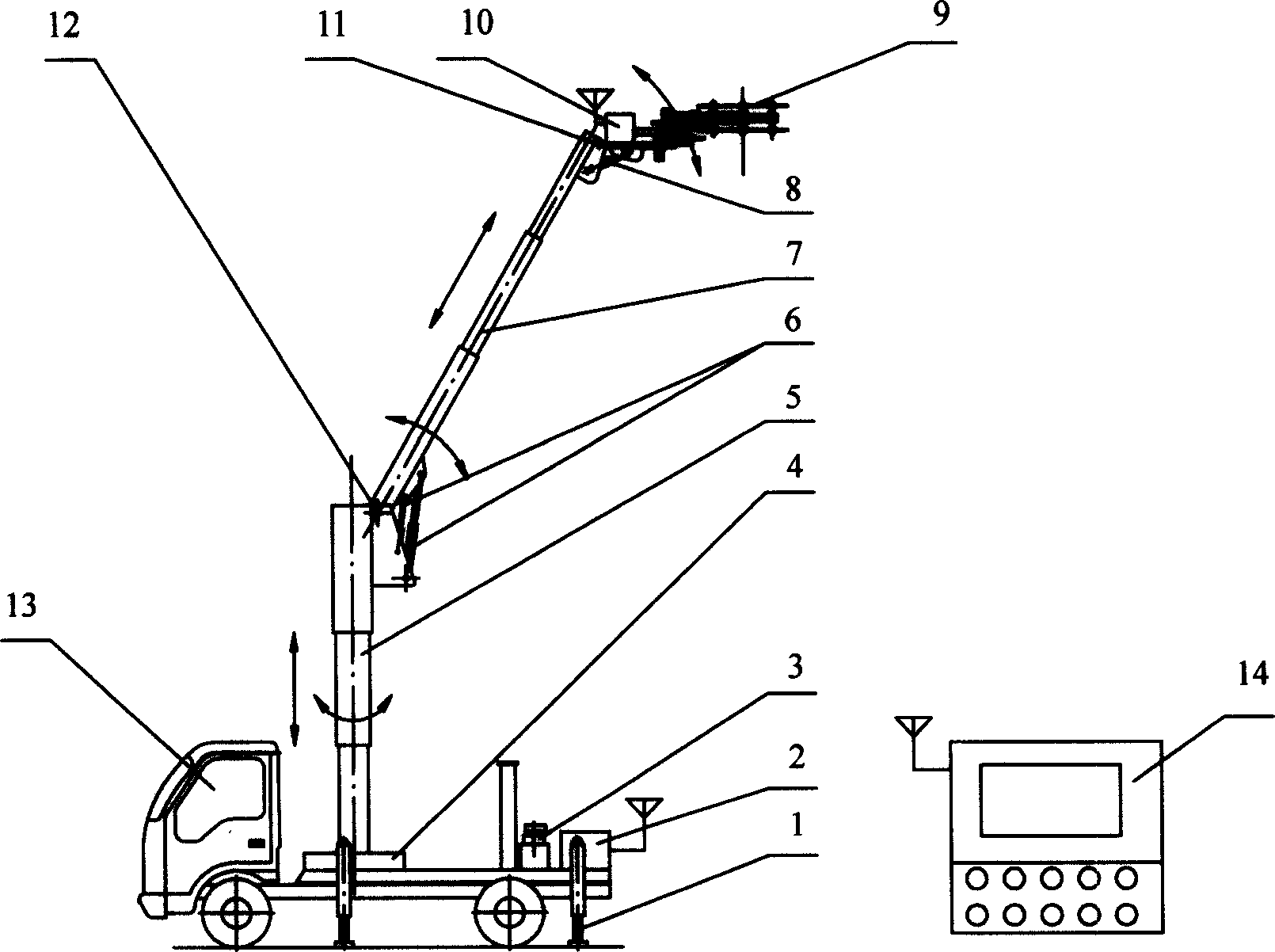

[0009] Such as figure 1 As shown, the present invention includes: a hydraulic automatic leveling system 1, a central control system 2, a cloud platform 3, a slewing platform 4, a boom 5, a small arm rotating cylinder 6, a small arm 7, a claw rotating cylinder 8, and a claw 9 , data acquisition system 10, movable joint 11, movable joint 12, mobile carrier 13 and teleoperation terminal 14. The connection method is: the claw 9 is connected to the forearm 7 through the movable joint 11; the piston rod of the claw rotating cylinder 8 is connected to the claw 9 through a hinge, and the cylinder 8 of the claw rotating cylinder is connected to the forearm 7 through a hinge. Above; the small arm 7 is connected to the large arm 5 through the movable joint 12, the piston rod of the small arm rotating cylinder 6 is connected to the small arm 7 through a hinge, and the cylinder barrel of the small arm rotating cylinder 6 is connected to the large arm 5 through a hinge; The boom 5 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com