Mold release agent composition for polyorganosiloxane adhesive and mold release plate using the composition

A polysiloxane and adhesive technology, applied in the direction of non-polymer adhesive additives, adhesive additives, film/sheet adhesives, etc., can solve the problem of increased peeling force over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

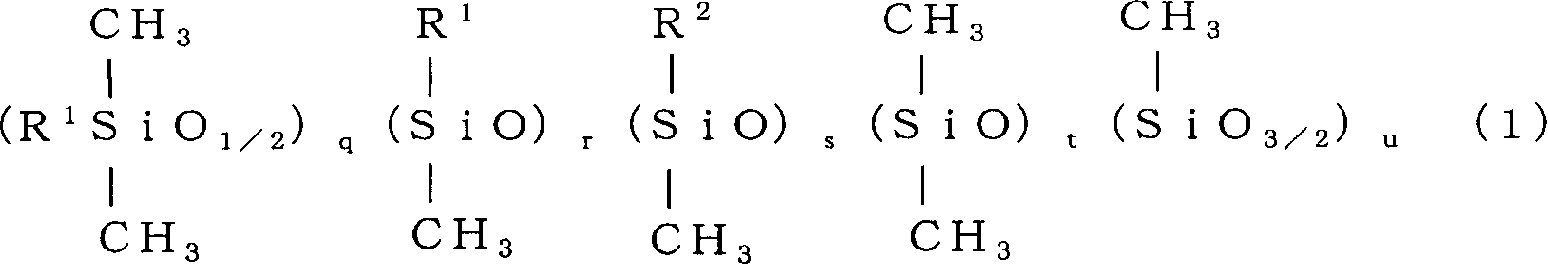

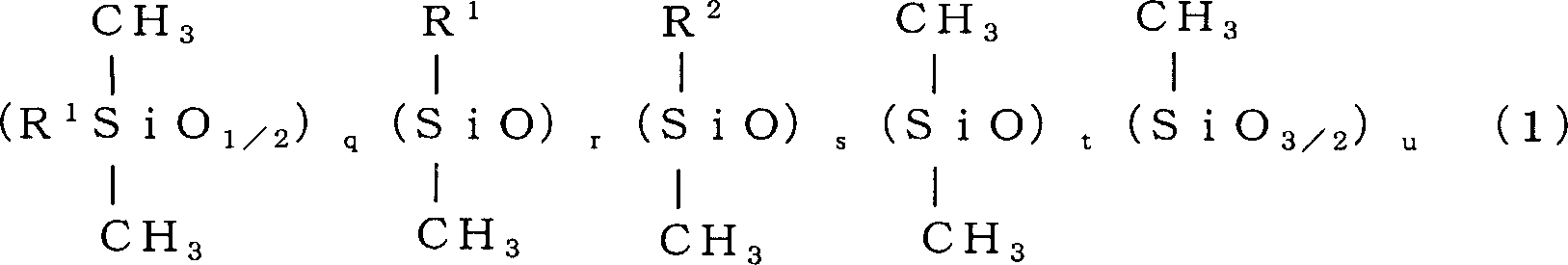

Method used

Image

Examples

Embodiment 1

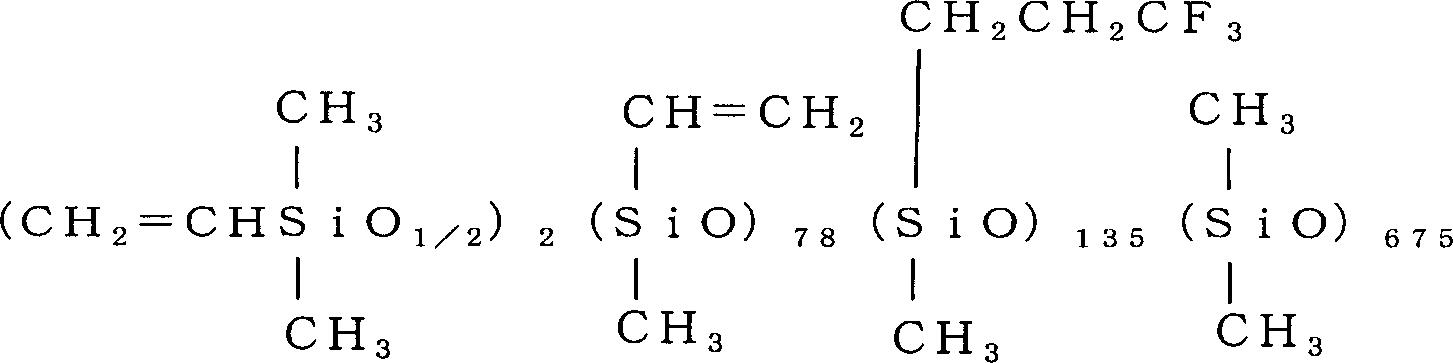

[0078] With 100 parts of fluoroalkyl-modified polydimethylsiloxane represented by the following formula as component (A) and label 1 in Table 1, as component (B), use trimethylsilane at both ends of the molecular chain Group-terminated, containing MeHSiO 2 / 2 23 parts of polymethylhydrogensiloxane with 95 mol% of units represented and a viscosity of 25 mPa·s, and 2 parts of 3-methyl-1-butyn-3-ol as component (D), mixed with toluene and heptane 900 parts of a mixture of alkanes (1:1 by weight) were diluted. Before coating on the substrate, a complex salt of platinum and vinylsiloxane as the component (C) was added in an amount of 100 ppm in terms of platinum to prepare a composition. The composition was treated under the aforementioned conditions, and the results are shown in Table 2.

Embodiment 2

[0080] 50 parts of the fluoroalkyl-modified polydimethylsiloxane represented by the following formula and the label 2-1 in Table 1 as the component (A), the fluoroalkane represented by the following formula and the label 2-2 in Table 1 50 parts of base-modified polydimethylsiloxane, as (B) component, both ends of the molecular chain are terminated with trimethylsilyl groups, containing MeHSiO 2 / 2 4 parts of polymethylhydrogensiloxane with 95 mol% units and a viscosity of 25 mPa·s; 2 parts of 3-methyl-1-butyn-3-ol as (D) component, used as (E) The ingredients were diluted with 900 parts of a mixture of toluene and heptane (1:1 by weight). Before coating on the substrate, a complex salt of platinum and vinylsiloxane as the component (C) was added in an amount of 100 ppm in terms of platinum to prepare a composition. The composition was treated under the aforementioned conditions, and the results are shown in Table 2.

Embodiment 3

[0082] With 100 parts of fluoroalkyl-modified polydimethylsiloxane represented by the following formula and number 3 in Table 1 as component (A), as component (B), use trimethylsilane at both ends of the molecular chain Group-terminated, containing MeHSiO 2 / 2 23 parts of polymethylhydrogensiloxane with 95 mol% units and a viscosity of 25 mPa·s, 2 parts of 3-methyl-1-butyn-3-ol as component (D), using toluene and heptane (by weight ratio 1:1) 900 parts of the mixture were diluted. Before coating on the substrate, a complex salt of platinum and vinylsiloxane as the component (C) was added in an amount of 100 ppm in terms of platinum to prepare a composition. Table 2 shows the results of treating the composition under the aforementioned conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com