White-light emitting device, and phosphor and method of its manufacture

A technology of emission device and manufacturing method, which is applied in the field of white light emission device, can solve the problems of low emission efficiency, low emission efficiency of white light, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

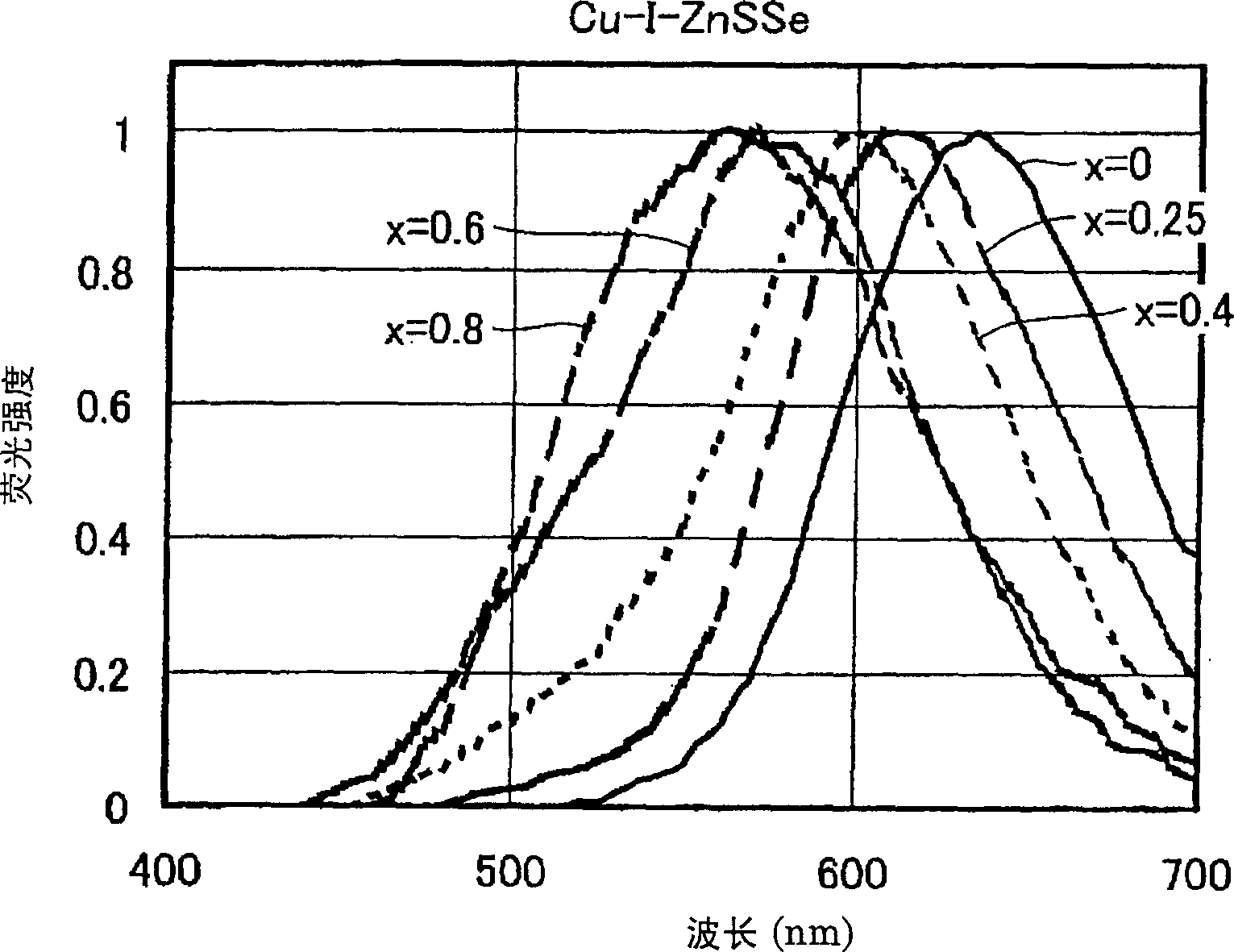

[0078] Figure 9 A white-light emitting device as described in was fabricated. First, ZnSSe crystals were grown using the iodine transport method and heat-treated at 1000 °C in an environment in which Zn and Cu vapors were mixed, thereby preparing a predetermined composite (ZnS atomic fraction 0.6) ZnS 0.6 Se 0.4 crystals. This phosphor corresponds to the diamond-shaped mark near the atomic percent of 0.6 of ZnS at a wavelength of 570 nm on the chromaticity diagram, and is a yellow-emitting phosphor. 250 µm thick ZnSSe plate from ZnS 0.6 Se 0.4 Cut out. Both sides of the ZnSSe plate were polished to a mirror-like shape, so that the thickness was reduced to 200 μm, and the polished plate was cut into 3 mm squares to produce ZnS 0.6 Se 0.4 Phosphor plate.

[0079] In addition, a blue LED chip with an emission wavelength of 450nm and an active layer of InGaN was prepared. Ag paste was used to bond the LED chip to the chip die (lead frame mounting part)9, as Figure 9 sh...

no. 2 example

[0081] Figure 10 A white-light emitting device as described in was fabricated. 250 µm thick ZnSSe plate from ZnS 0.6 Se 0.4 crystal (ZnS atomic percent 0.6) cut out, the ZnS 0.6 Se 0.4 Crystals were first grown using the iodine transport method, and then heat-treated in a 1000° C. environment in which Zn and Ag vapors were mixed. This phosphor is marked by a black dot with a ZnS atomic fraction of 0.6 on the chromaticity diagram and is a green-emitting phosphor. Both sides of the ZnSSe plate were polished to a mirror-like finish so that the thickness was reduced to 200 μm, and the polished plate was cut into 3 mm squares to produce a ZnSSe phosphor plate (green phosphor: first phosphor).

[0082] In addition, 400 micron square, 250 micron thick ZnS 0.25 Se 0.75 Phosphor plate (red phosphor: second phosphor) from ZnS 0.25 Se 0.75 Crystal (ZnS atomic percentage 0.25) preparation, the ZnS 0.25 Se 0.75 Crystals were grown using the iodine transport method and heat trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com