Preparation method of nanometer sized superfine ferro nickel alloy powder

A nickel-iron alloy, nano-level technology is applied in the field of preparation of nano-level ultra-fine nickel-iron alloy powder, which can solve the problems of inability to large-scale production, serious environmental pollution, large equipment investment, etc. The effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

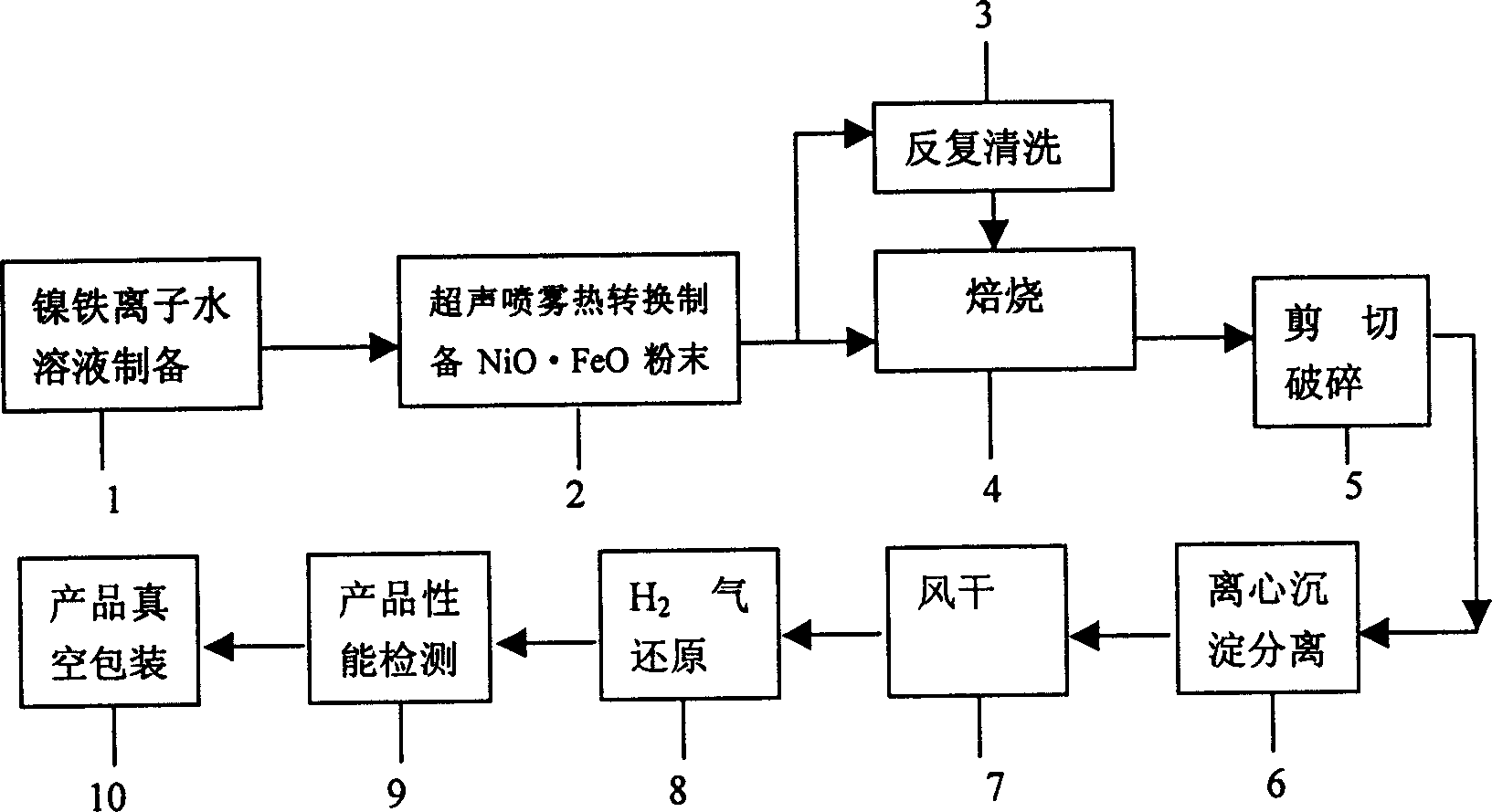

Method used

Image

Examples

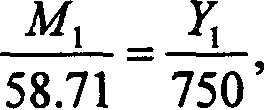

Embodiment 1

[0048] Embodiment 1: When preparing 1 kg of nano-nickel-iron alloy powder, the composition is Ni:Fe=3:1, it should be completed according to the following steps.

[0049] 1. Weigh 1244.52 grams of FeSO 4 ·7H 2 O and 3357.8 g NiSO 4 ·6H 2 Add the O powder into 10 liters of distilled water, heat it to 60°C and stir continuously, after it is completely dissolved, use a 40μm sieve to filter out foreign impurities, and then transfer the solution into the atomizing liquid tank.

[0050] 2. Airflow ultrasonic spray heat conversion, using annular seam resonant airflow ultrasonic atomizing nozzle with injection angle α = 45°, injection pressure (air) 2.5MPa, hot air temperature 128°C, airflow injection speed 2-2.5 Mach number, liquid flow The delivery speed is 200ml / min. After the solution is completely atomized, the dry precursor powder can be obtained, and it will be transferred to the repeated cleaning stage.

[0051] 3. Repeated cleaning and centrifugation. The precursor powder...

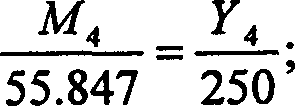

Embodiment 2

[0057] Example 2 To prepare 10kg of nano-nickel-iron alloy powder, the alloy composition is Ni: Fe=3: 1, it should be completed according to the following steps.

[0058] 1. Weigh Ni(NO 3 ) 2 ·6H 2 O, 37.1487kg; Fe(NO 3 ) 3 9H 2 O, 18.0851kg, crystal powder, added to 120 liters of distilled water, heated to 50°C in a stainless steel reaction tank, stirred continuously and completely dissolved, then poured the solution into the liquid tank of the atomization tower through a 44μm screen filter pipe with a liquid pump Perform spray heat transfer.

[0059] 2. Airflow spray heat conversion

[0060] Use a circular slot resonant airflow ultrasonic atomizing nozzle with a spray angle of α = 45°, spray pressure (air) 3.5MPa, hot air temperature 68°C, liquid flow delivery speed 200ml / min, and dry precursor can be obtained after the solution is completely atomized The body powder is transferred to the roasting process.

[0061] 3. Put the precursor powder obtained in the above 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com