Chain bucket digging type floating ship for metal tailings stoping

A technology of metal tailings and chain buckets, which is applied to ship accessories, solid separation, ships, etc., can solve the problems of unreasonable setting of chain bucket suspension mechanisms, poor adaptability, and low recovery rate, so as to improve maneuverability and reduce chain load. The effect of reducing the weight of the bucket and reducing the cost of the hull

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

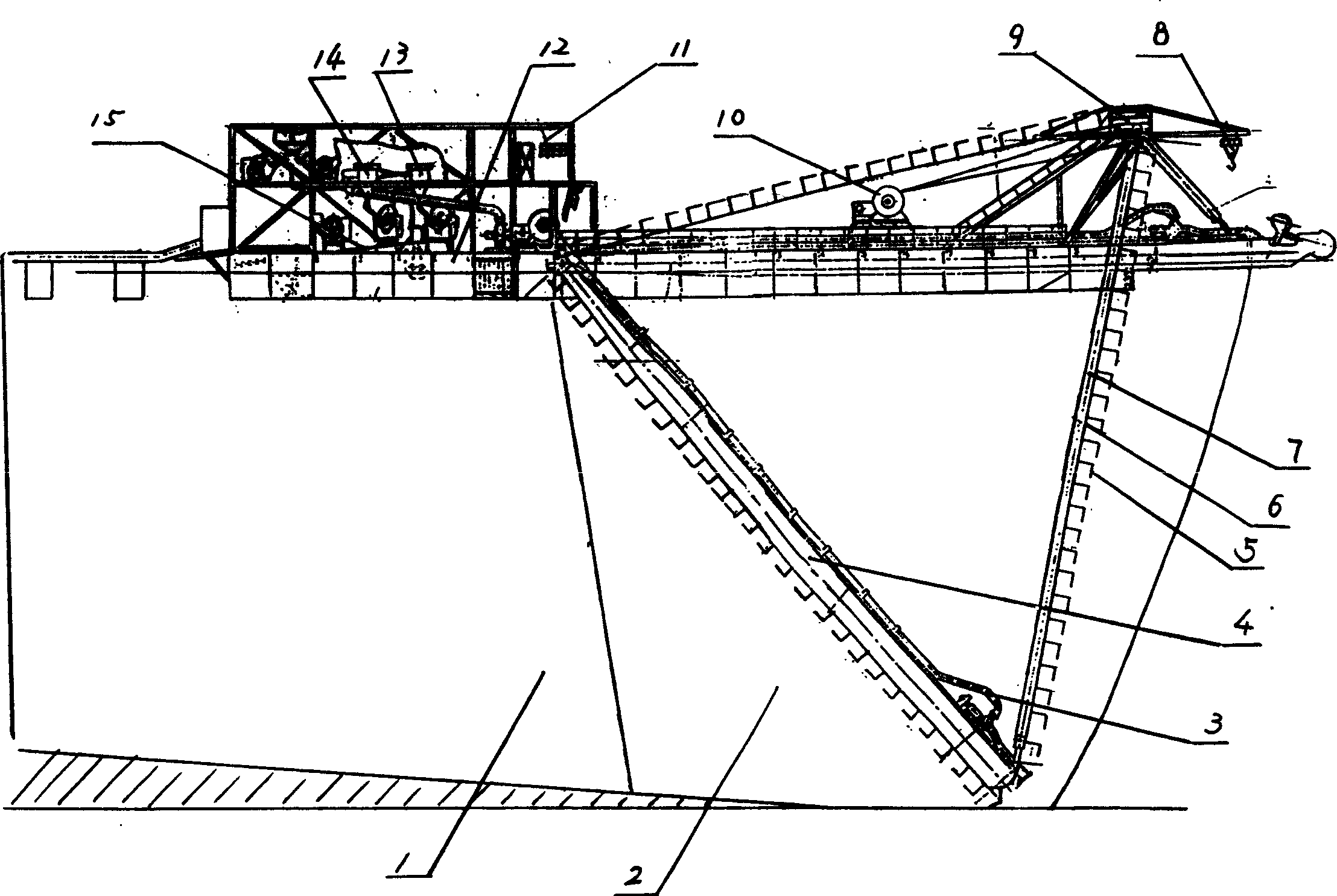

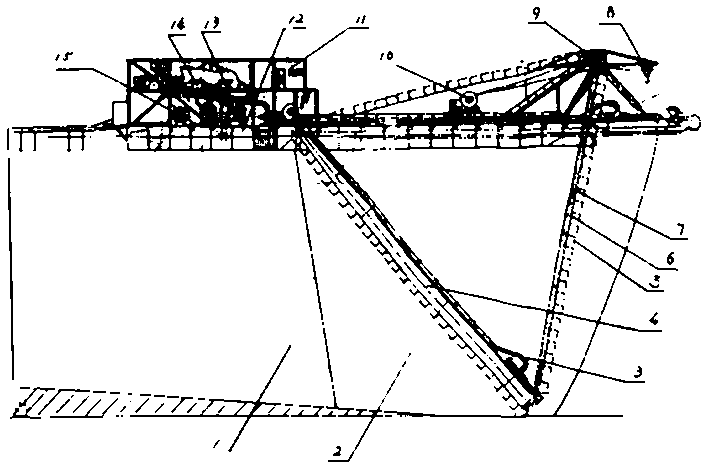

[0008] root knot figure 1 As shown, the recovery hull 1 is a non-self-propelled engineering ship, its bow 2 is a concave double body structure, the deck of the hull 1 is a recovery platform, and the deck machinery 9 is located on the front deck of the recovery hull, including lifting devices 10, hoisting and suspension Mechanism 8 and corresponding hoisting equipment, chain bucket long arm 4 and chain bucket bridge 7 form a triangle chain bucket suspension mechanism, which is hoisted and suspended by deck machinery 9, on which there is a circulating conveyor belt 6 and chain bucket 5, and the chain bucket suspension mechanism is set Between the concave catamaran bow 2, the lifting device 10 of the deck machinery 9 can control its lifting in the middle of the concave hull structure, so as to be suitable for tailings mining operations at different depths. One end of the long arm 4 of the chain bucket is hinged on On the front deck of the mining hull 1, the conveying pipeline 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com