Water level control method of water tank

A water level control and water tank technology, applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve problems such as poor control effect and large water level fluctuation, and achieve fast response speed, simple equipment and good control effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

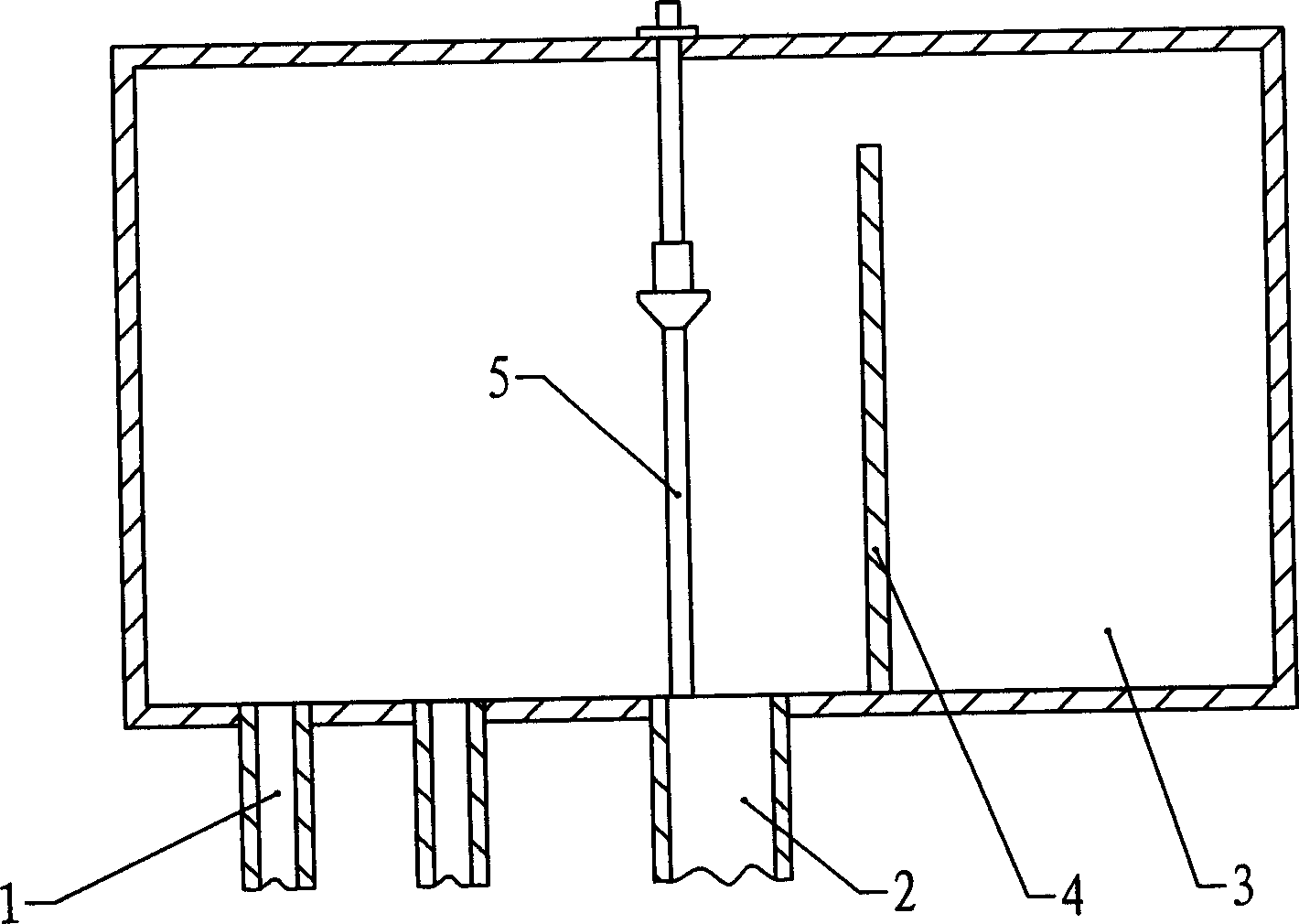

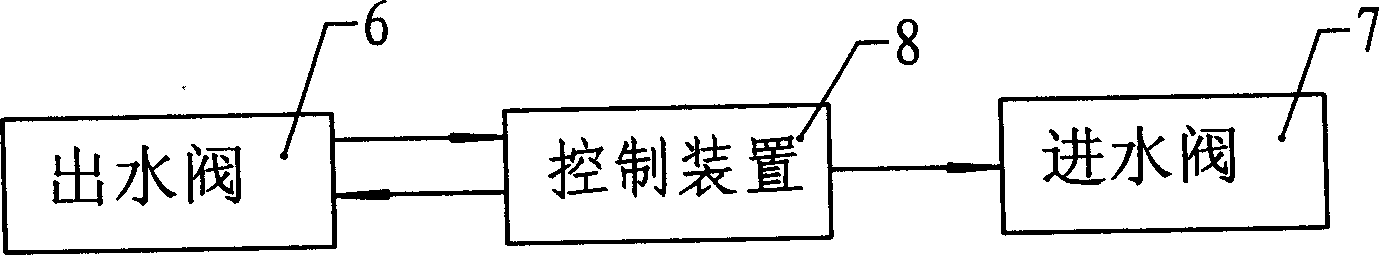

[0012] Example: such as figure 1 , figure 2 Shown, the water tank water level control method of the present invention, the structural shape of its high-level water tank, the configuration of control device 8 etc. are the same as traditional ones. The water level gauge 5 only takes the function of displaying the water level, and the action of replenishing water does not depend on the detection results. Therefore, the requirements for the accuracy, sensitivity, stability and other characteristic values of the water level gauge 5 are lower than those of the traditional method. The water tank 3 is divided into two parts by the grille 4, and the left side is the water storage tank, which is equipped with 10 large caliber water supply pipes 2 with the same water inlet valve 7 and 90 small caliber water outlet pipes with the same water outlet valve 6. Water pipe 1, water inlet valve 7 and water outlet valve 6 are electromagnetic control valves. The total height of water tank 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com