Vacuum sintering method of negative plate of nickel-hydrogen battery

A technology of vacuum sintering and nickel-metal hydride batteries, which is applied in the manufacture of alkaline battery electrodes and electrodes, and can solve the problems of cooling speed and shape structure not suitable for manufacturing plates, poor battery resistance to overcharging and over-discharging, and plate unit density Small problems, to achieve the effect of large specific energy, high capacitance, high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

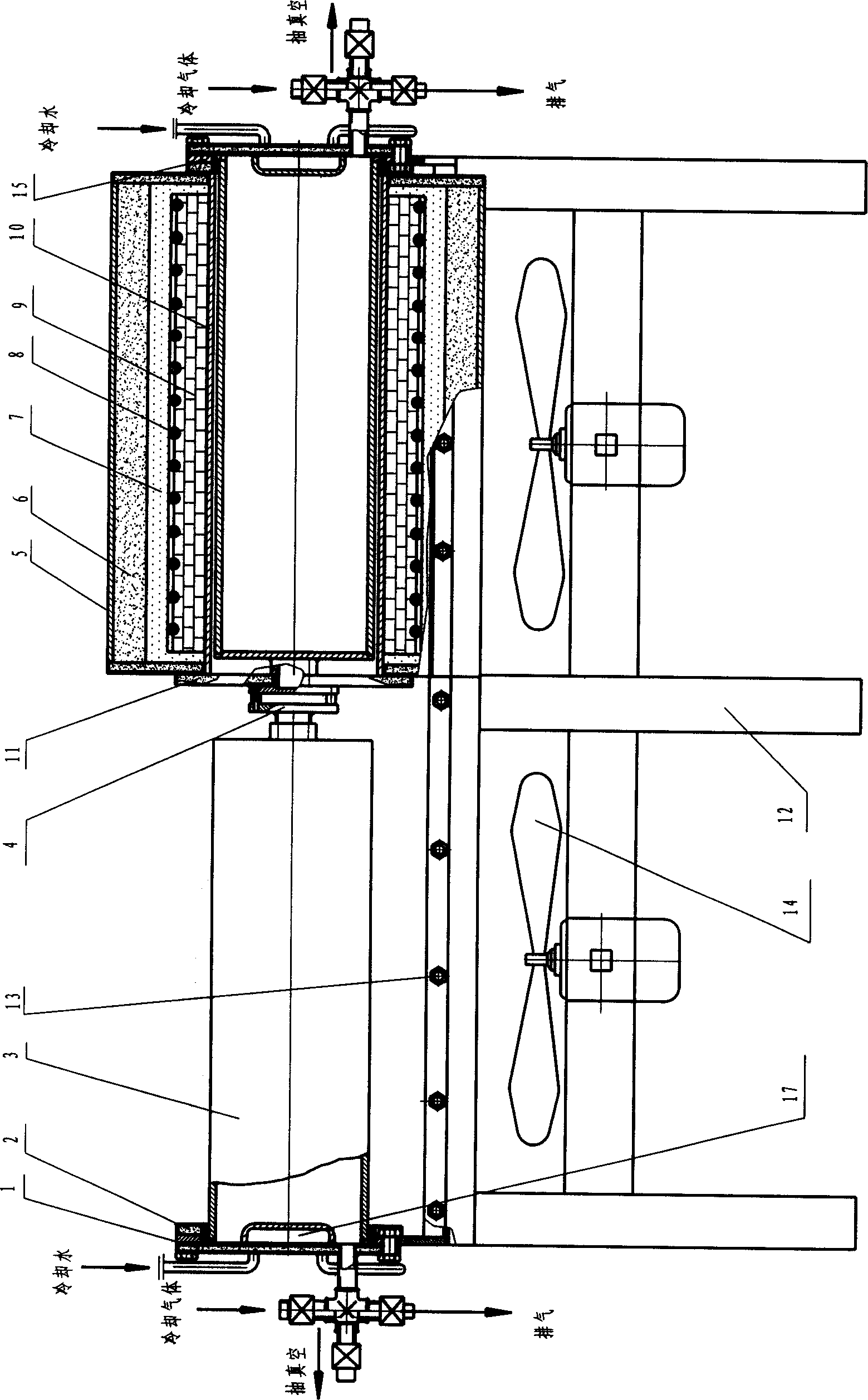

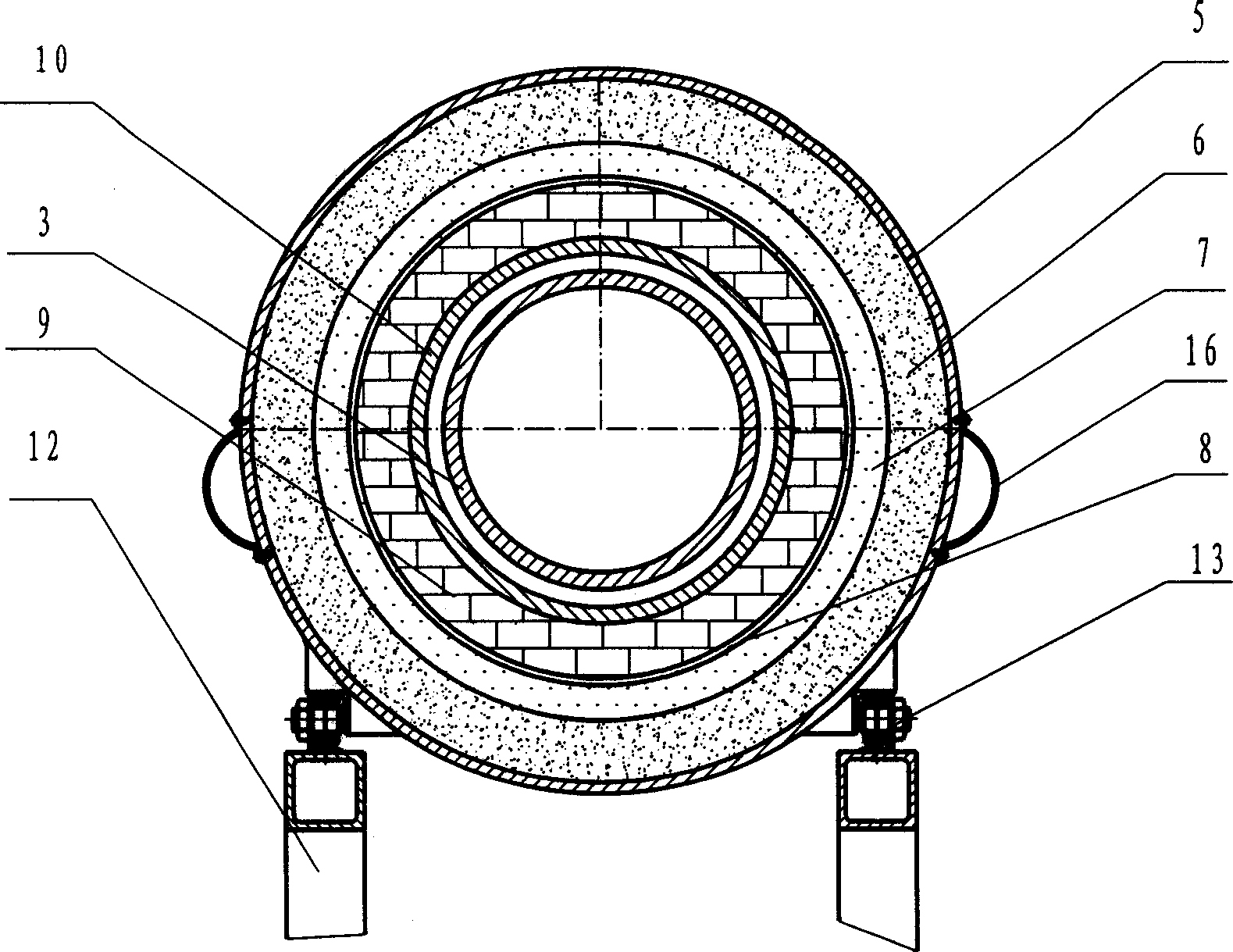

[0021] The present invention is a vacuum sintering and cooling protection process in the manufacturing process of the negative plate of the nickel-hydrogen battery. The whole process flow of the negative plate of the nickel-hydrogen battery is: mixing powder → continuous pressing forming → cutting, weighing, inspection → vacuum sintering → Cooling protection → out of the oven inspection package.

[0022] With reference to the above process flow and the technical solution disclosed in the present invention, it can be seen that the process flow before vacuum sintering and cooling protection is also particularly important. The negative electrode plate of the press molding described in the technical solution of the present invention must be: mixed with different particle sizes The alloy powder is sieved and stirred evenly, and the mixed powder and nickel-plated steel strip are molded by a double-roller molding machine, and the inspection standards are strictly followed. Only negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com