Metal cutting equipment facilitating collecting of metal scraps

A metal cutting and metal chip technology, applied in metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of difficult recycling, easy to splash around, and achieve easy curling and spreading, improve interception effect, The effect of increasing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

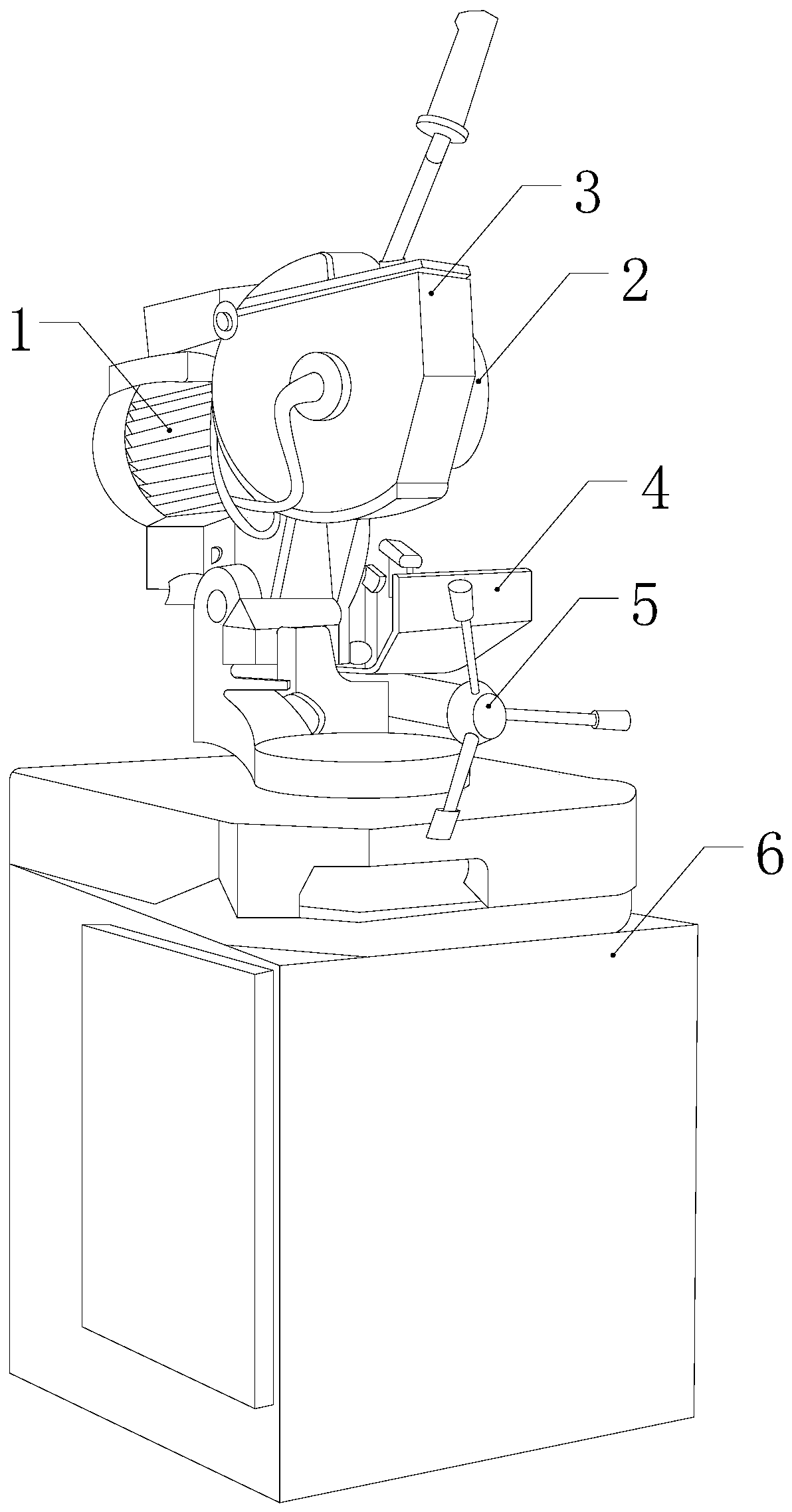

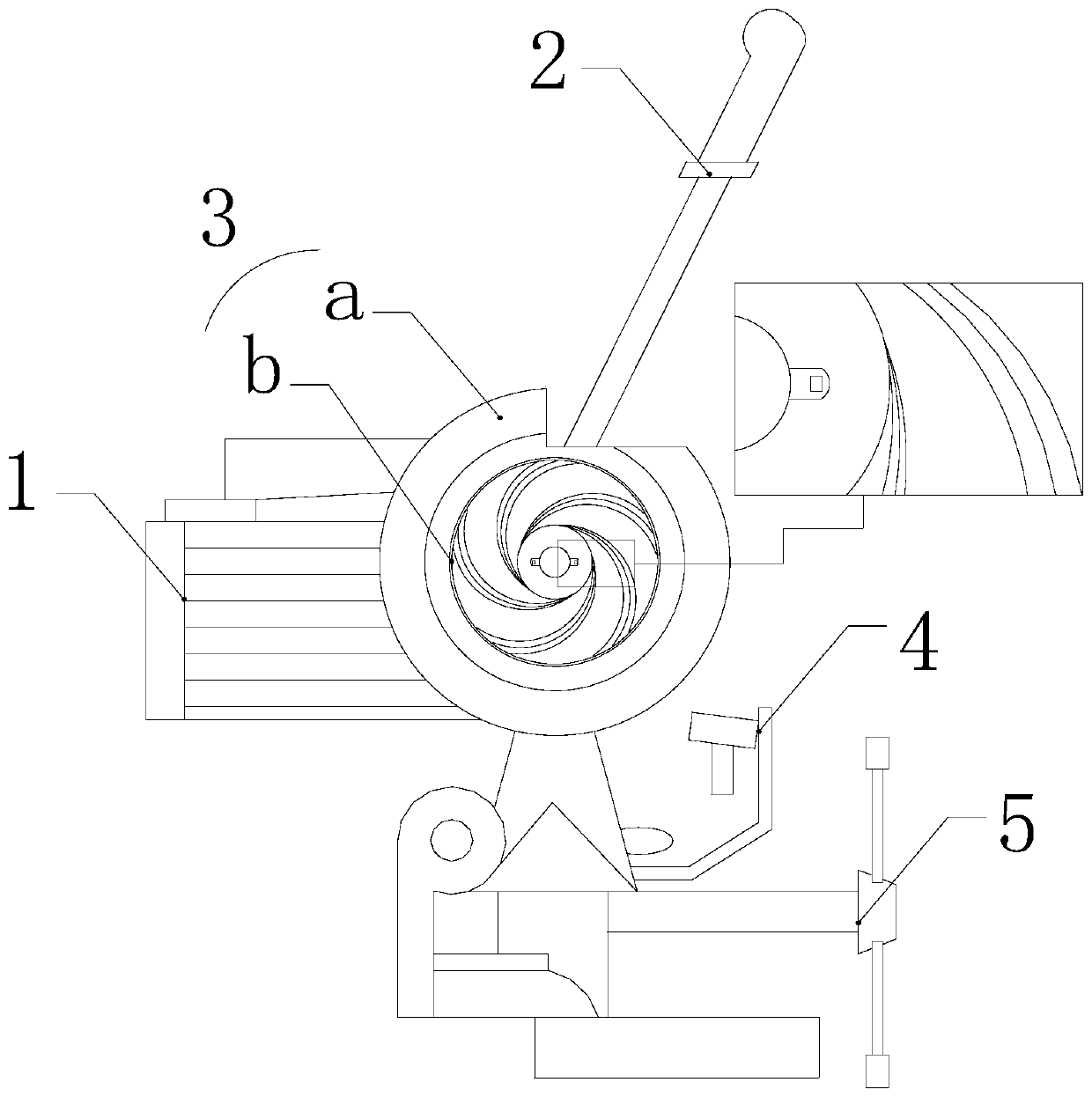

[0026] see Figure 1-Figure 4 , a kind of metal cutting equipment that is convenient for collecting metal shavings. The present invention provides a kind of metal cutting equipment that is convenient for collecting metal shavings. , the top of the body 6 is provided with an underframe 4, the top of the underframe 4 is provided with a cutting knife 2, the side of the cutting knife 2 is equipped with a curling collection structure 3, and the underframe 4 facing the underframe 4. A steering wheel 5 is provided at the bottom, and a motor 1 is installed on the other side of the cutting knife 2 corresponding to the steering wheel 5. The curl collection structure 3 is composed of a casing a and a curl inclusion b. On the knife 2, a curling inclusion b is arranged in the middle of the inside of the casing a, and the curling inclusion b is facing the cutting knife 2.

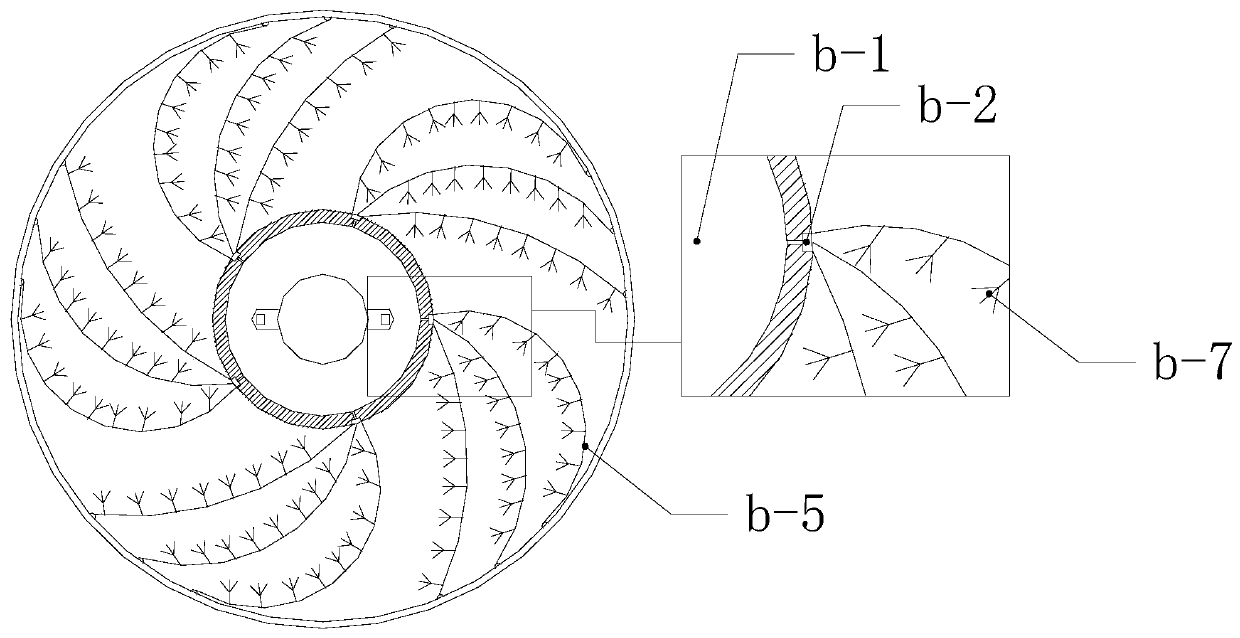

[0027] The twisted inclusion b is provided with an adapter b-2, an inner cylinder b-3, a mesh bar b-4, an outer ring ...

Embodiment 2

[0031] see Figure 1-Figure 5 , a kind of metal cutting equipment that is convenient for collecting metal shavings. The present invention provides a kind of metal cutting equipment that is convenient for collecting metal shavings. , the top of the body 6 is provided with an underframe 4, the top of the underframe 4 is provided with a cutting knife 2, the side of the cutting knife 2 is equipped with a curling collection structure 3, and the underframe 4 facing the underframe 4. A steering wheel 5 is provided at the bottom, and a motor 1 is installed on the other side of the cutting knife 2 corresponding to the steering wheel 5. The curl collection structure 3 is composed of a casing a and a curl inclusion b. On the knife 2, a curling inclusion b is arranged in the middle of the inside of the casing a, and the curling inclusion b is facing the cutting knife 2.

[0032] The twisted inclusion b is provided with an adapter b-2, an inner cylinder b-3, a mesh bar b-4, an outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com