High-strength and wear-proof PP plastic rope

A high-strength, plastic technology, applied in the field of plastics, can solve the problems of reducing the mechanical properties and flexibility of the plastic body, and achieve the effects of increasing stress, improving wear resistance, and improving mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation method of modified polypropylene is:

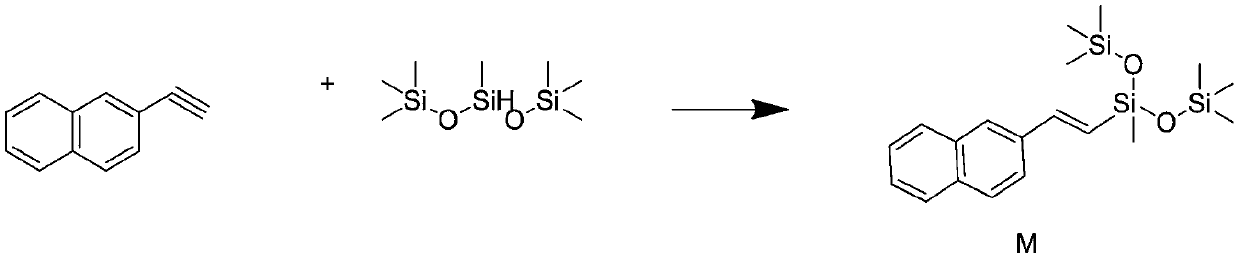

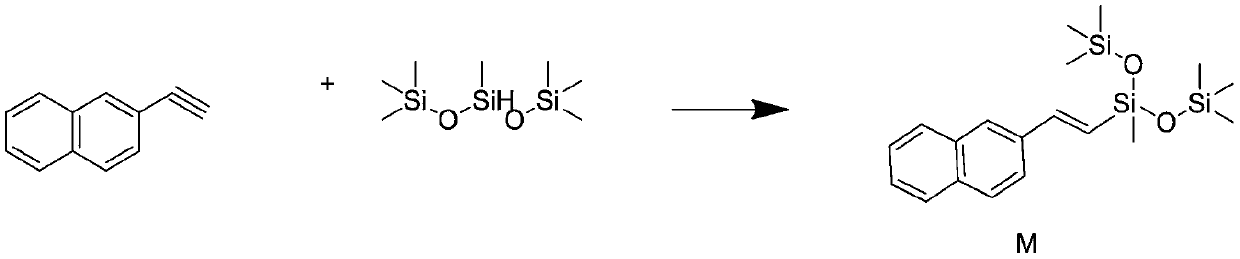

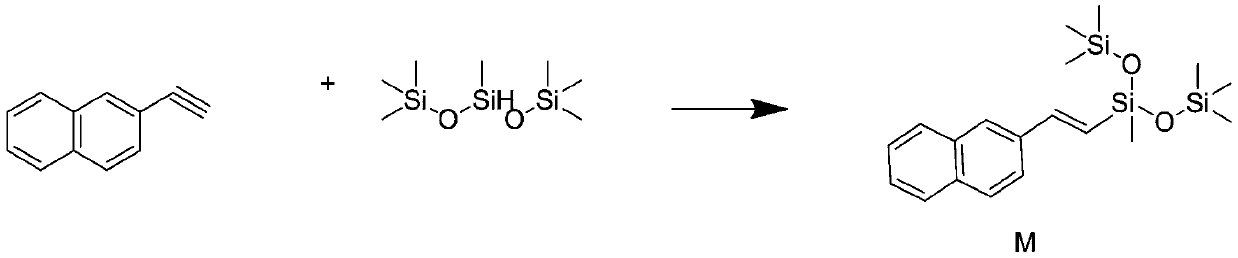

[0023] S1, preparation of modifier

[0024] Add 1mol 2-acetylene naphthalene, 1.15mol bistrimethylsiloxymethylsilane, 5mmol catalyst chloroplatinic acid and 1L solvent toluene into the reaction kettle, feed nitrogen for 15min, replace the air in the reaction kettle, and stir Heat up to 80°C, keep warm and stir for 11 hours. After the reaction, remove the solvent by rotary evaporation, wash with anhydrous ether, and dry to obtain the modifier shown in formula M; the yield is 83.6%; the reaction formula is as follows :

[0025]

[0026] S2, preparation of modified polypropylene

[0027] Add 1 kg of deionized water, 2 g of emulsifier polyoxypropylene ether, 1.5 g of initiator sodium persulfate, and 65 g of propylene monomer into the reactor, transfer the reactor to a water bath, and perform prepolymerization at a temperature of 60 ° C 30min, then the reactor was moved out of the water bath, cooled to room tempera...

Embodiment 2

[0029] A high-strength wear-resistant PP plastic rope, including the following raw materials in parts by weight: 110g modified polypropylene, 6g dimethyl phthalate, 6g trimethyloxalate acetate, 20g filler, 1g plasticizer , 1.6g paraffin oil, 0.5g lubricant.

[0030] Described filler is calcium carbonate;

[0031] Described plasticizer is epoxy fatty acid methyl ester;

Embodiment 3

[0034] A high-strength and wear-resistant PP plastic rope, including the following raw materials in parts by weight: 140g modified polypropylene, 8g dimethyl phthalate, 8g trimethyloxalate acetate, 15g filler, 1.2g plasticizer Agent, 2g paraffin oil, 1g lubricant.

[0035] Described filler is montmorillonite;

[0036] Described plasticizer is diethyl terephthalate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com