Structure of LED and its mfg method

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as complicated manufacturing processes, and achieve the effects of reducing volatilization, stabilizing voltage, and optimizing current distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

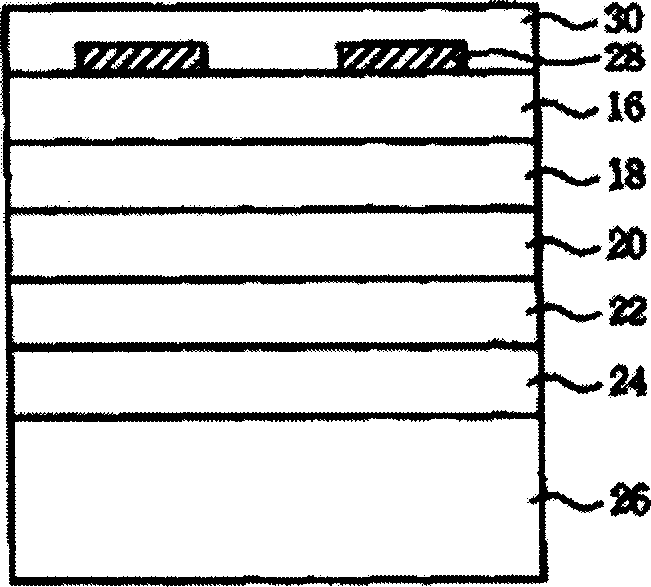

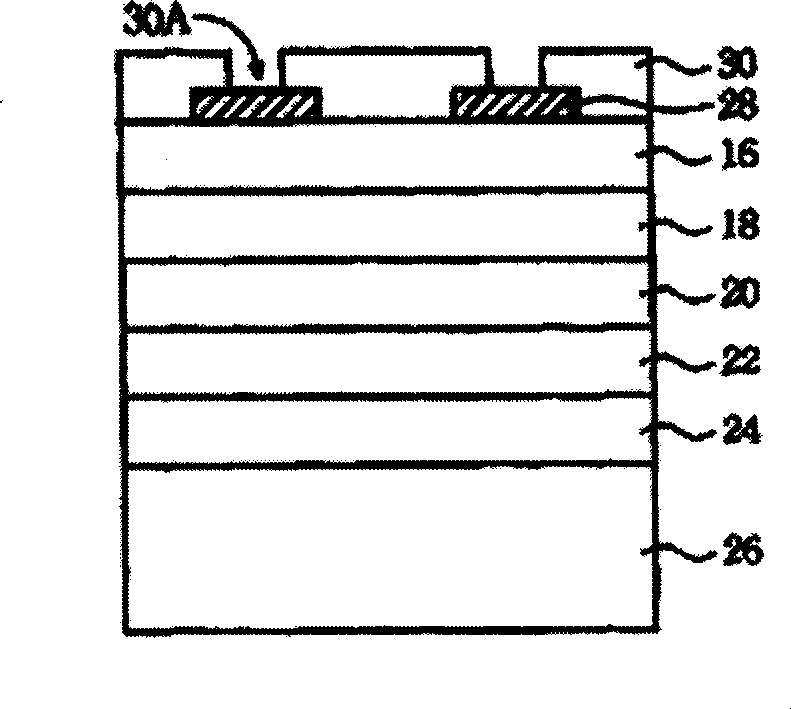

[0042] The invention discloses a light emitting diode structure and a manufacturing method thereof.

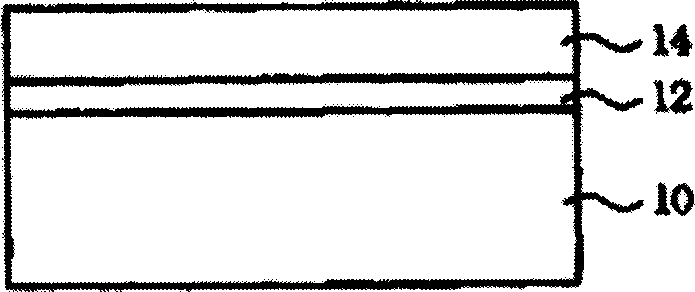

[0043] Such as Figure 1A As shown, the epitaxial structure of the light-emitting diode of the present invention includes an N-type gallium arsenide (GaAs) substrate 26, an etching stop layer (Etching Stop Layer) 24, an N-type aluminum gallium indium phosphide (AlxGa1-x) stacked in sequence. 0.5In0.5P lower cladding (Cladding) layer 22 and aluminum gallium indium phosphide (AlxGa1-x) 0.5In0.5P active layer (Active Layer) 20, P-type aluminum gallium indium phosphide (AlxGa1-x) 0.5 An upper cladding layer 18 of In0.5P and a P-type Ohmic Contact Epitaxial Layer (Ohmic Contact Epitaxial Layer) 16 . Next, a P-type ohmic contact metal electrode layer (first ohmic contact metal electrode layer) 28 is formed on the P-type ohmic contact epitaxial layer 16 by conventional techniques. Subsequently, a mirror protection layer 30 is deposited thereon, and the above-mentioned mirror protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com