Nano laser measuring rule and subdivision method for nano measurement realization

A nano-laser and laser technology, applied to the structure/shape of lasers, laser components, optical resonators, etc., can solve the problems of four-zone unevenness, keeping the same, four-zone unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

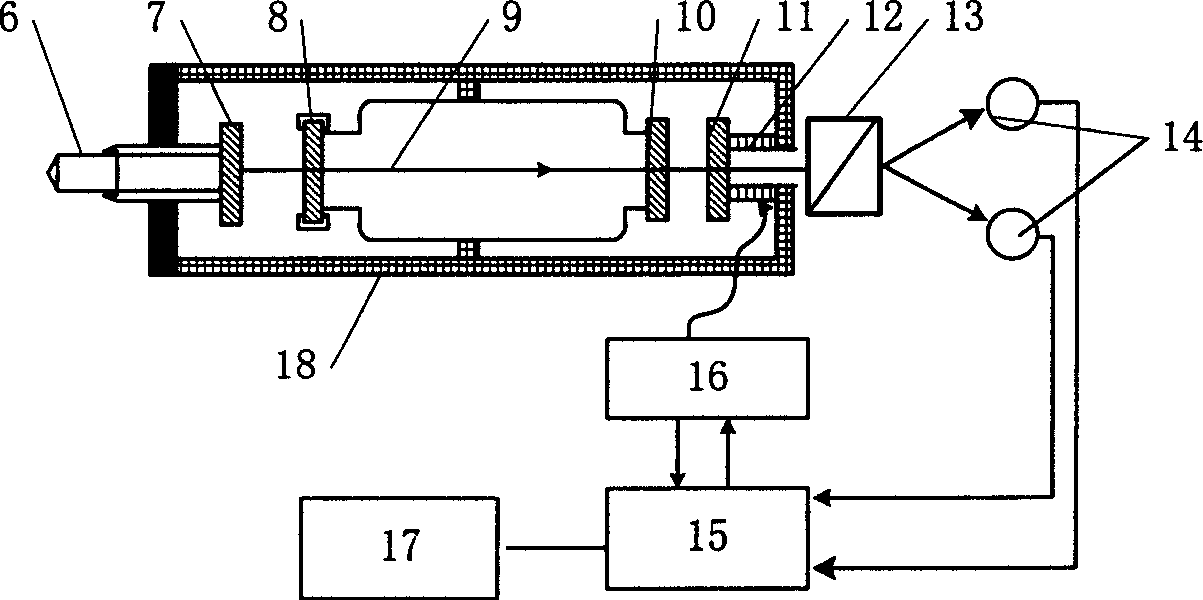

[0066] Embodiment 1; ( figure 2 )

[0067] The cat's-eye reverse mirror 7 on the movable measuring rod 6 (which is in contact with the object to be measured and moves due to displacement) passes through the anti-reflection windows 8 and 10, together with the gain tube 9 and the concave output mirror 11 to form a HeNe laser with a full external cavity. The force ring on the anti-reflection window 8 makes it a stress birefringent element, which turns the single-frequency laser into orthogonally polarized light with two frequencies and outputs it from 11 . The concave output mirror 11 is adhered to a micro-displacement piezoelectric sensor, that is, PZT, 12, and can be moved slightly. The orthogonally polarized light is split by the polarizing beam splitter 13 and projected onto two photodetectors 14 respectively. In circuit 15, the optical signal is converted into an electrical signal and processed. During the measurement process, 15 can send a scanning signal to drive the P...

Embodiment 2

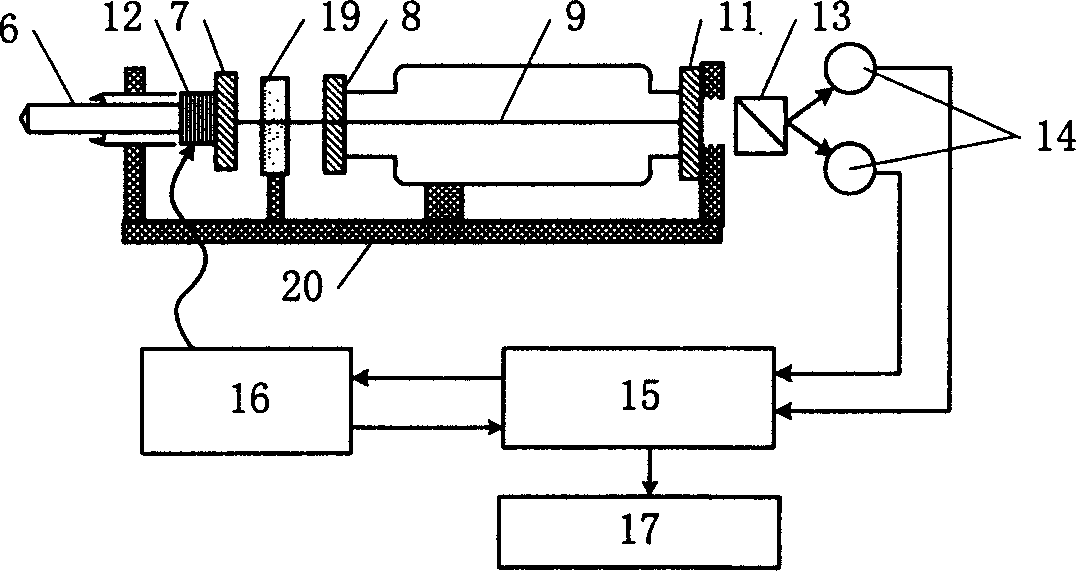

[0068] Embodiment 2: ( image 3 )

[0069] Same as Example 1, the cat's-eye reverse mirror 7 on the movable measuring rod 6 constitutes a half-cavity HeNe laser through the anti-reflection window 8, the gain tube 9 and the concave output mirror 11. and figure 2 The difference is that the frequency splitting of the laser is not caused by the stress birefringence but by the crystal quartz19. The PZT 12 is not connected with the concave output mirror 11 but adhered between the measuring rod 6 and the cat's eye 7 . The laser beam is also split by the polarization beam splitter 13 and projected onto the photodetector 14 . Circuit 15 processes the optical signal, calculates the measurement result and sends 17 to display the output. A high voltage amplifier 16 is controlled by 15 to drive the PZT 12 . Except for the circuit part, all components of the system are installed on the tablet support 20 .

[0070] For the specific block diagram of circuit 15, see Figure 4 , see the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com