Grounding brush for mitigating electrical current on motor shafts

A technology of electrostatic charge and rotating shaft, applied in the direction of electromechanical device, static electricity, connection with grounding device, etc., can solve problems such as rapid wear of copper brushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

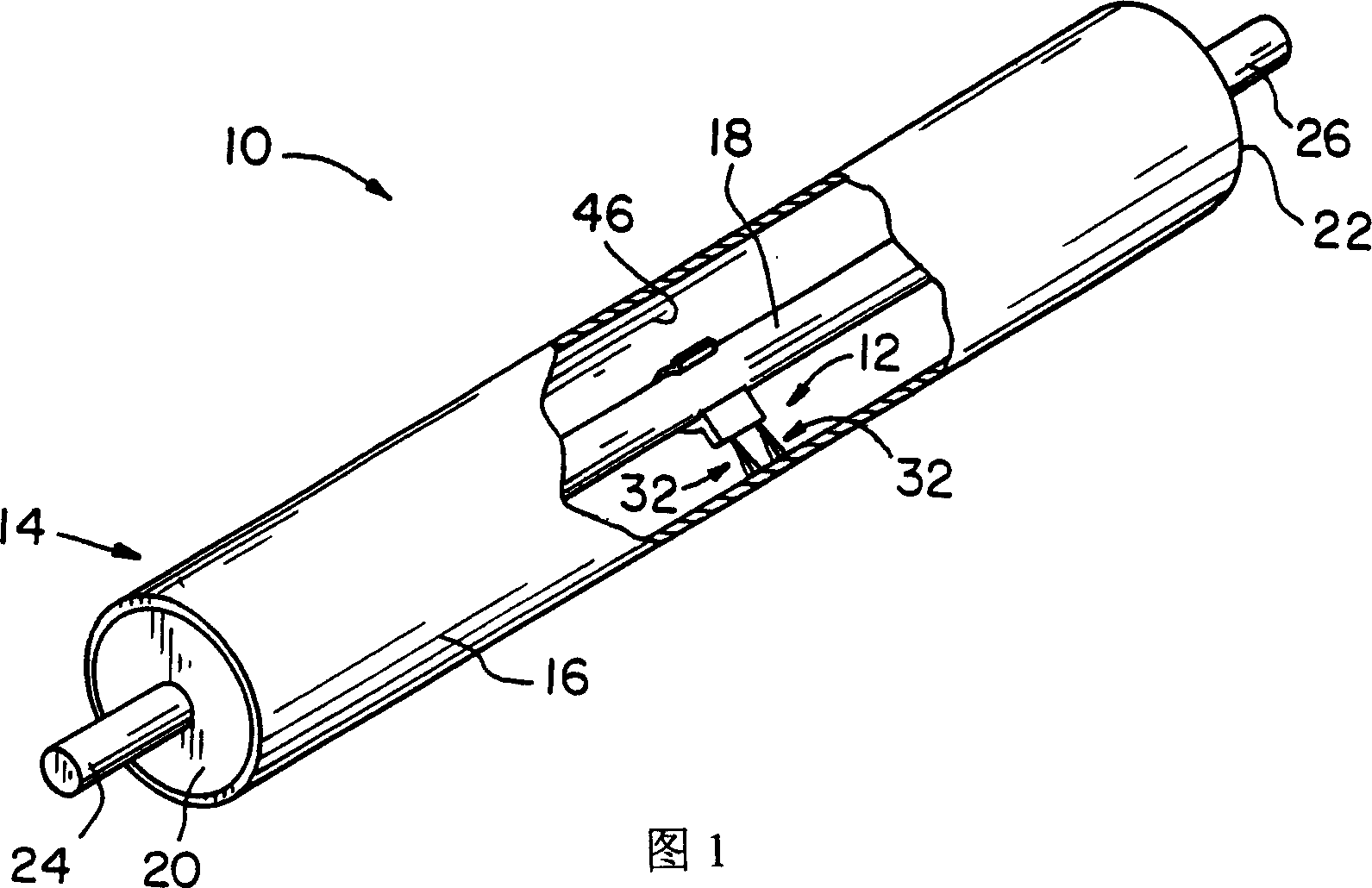

[0027] Referring now more specifically to the drawings, and in particular to FIG. 1 , there is shown a roller assembly 10 comprising a static charge neutralization device 12 of the present invention operatively mounted on a roller 14 for dissipating the static charge on the roller 14. electrostatic charge buildup on the In the exemplary embodiment shown, the rollers 14 are transport rollers, but other roller types are possible for other purposes.

[0028] Roller 14 includes a hollow tubular casing 16 mounted for rotation on an axis of rotation 18 . The tube case 16 includes both ends 20 and 22 mounted with bearings or the like on a rotary shaft 18 completely passing through the tube case 16 . The ends 24 and 26 of the rotating shaft 18 protrude beyond the roller ends 20 and 22, thereby providing a structure in which the roller 14 can be operatively mounted in an apparatus or machine.

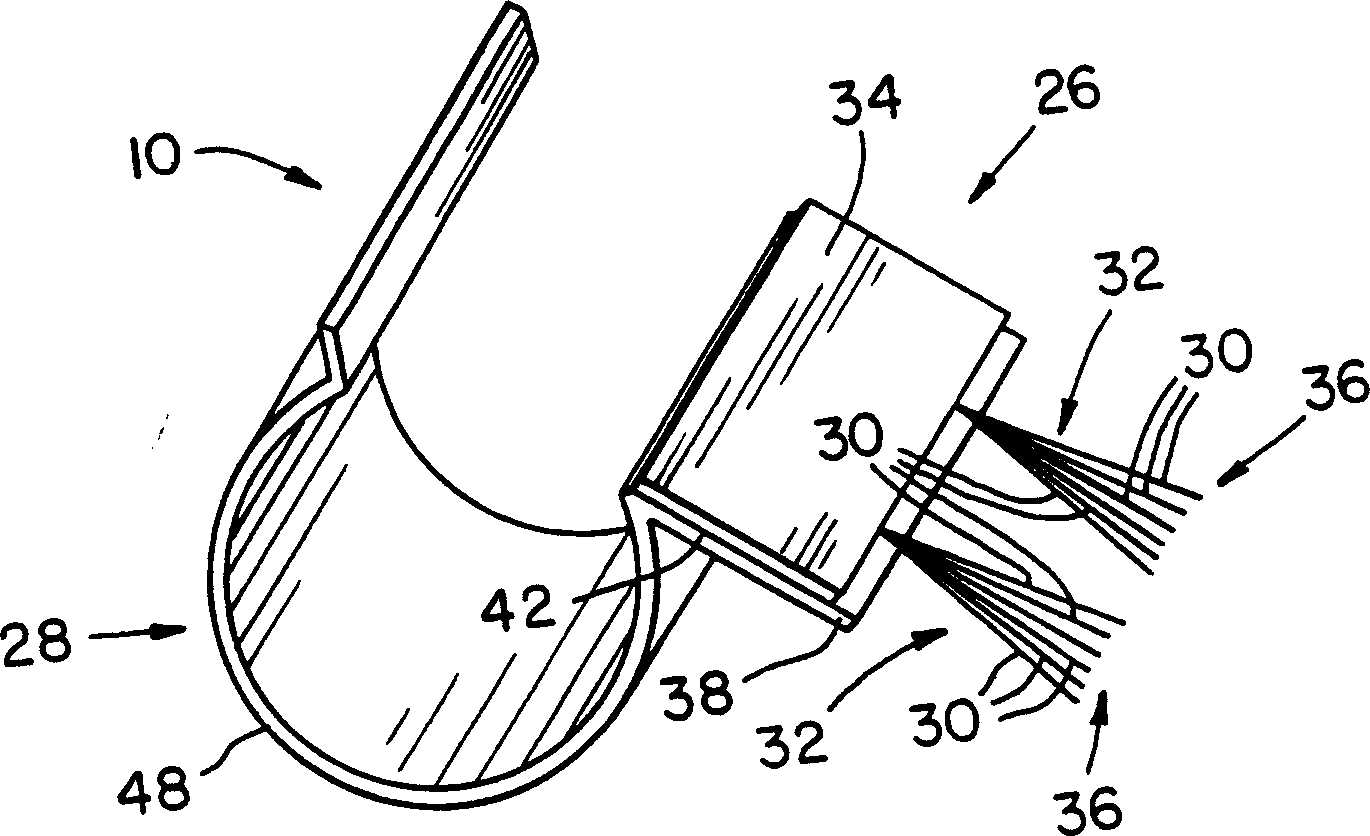

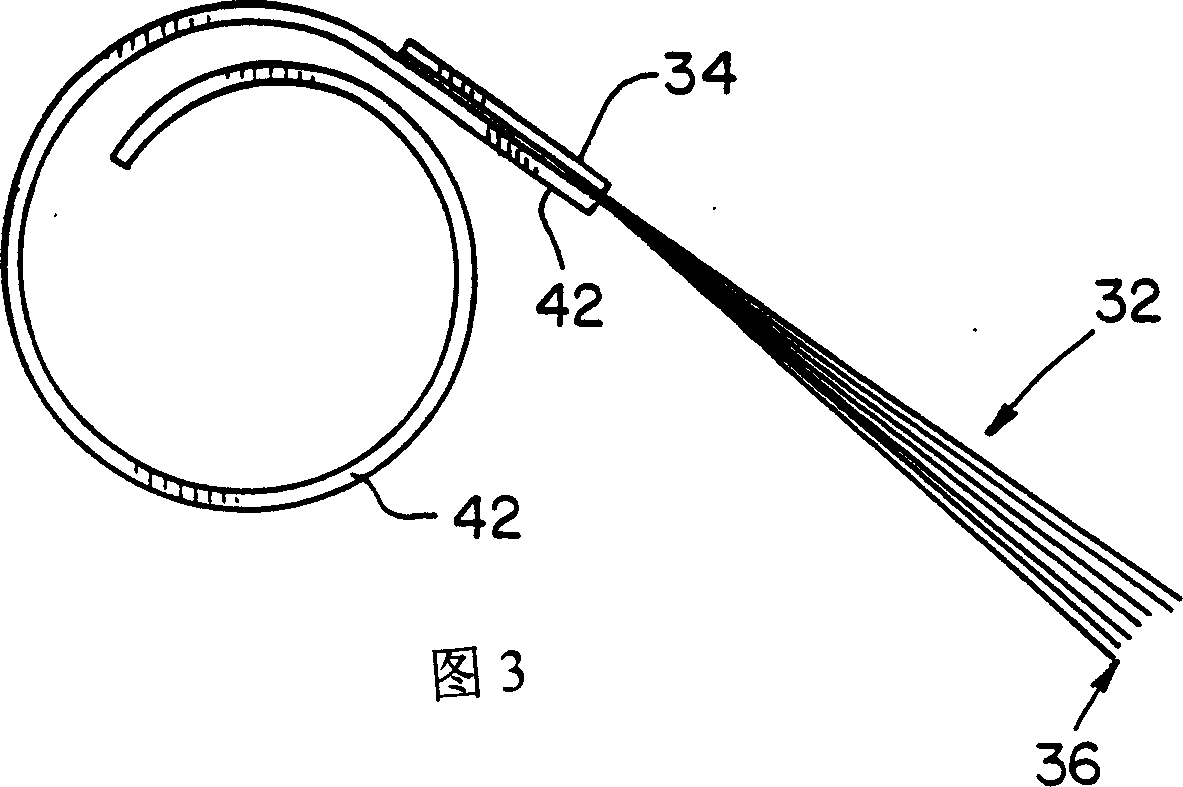

[0029] The static neutralization device 12 is housed in the envelope 16 and includes a mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com