Leakage sensor and leakage detection system

A detection system, sensor technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, testing machine/structural parts, etc. Inability to be practical and other problems to achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

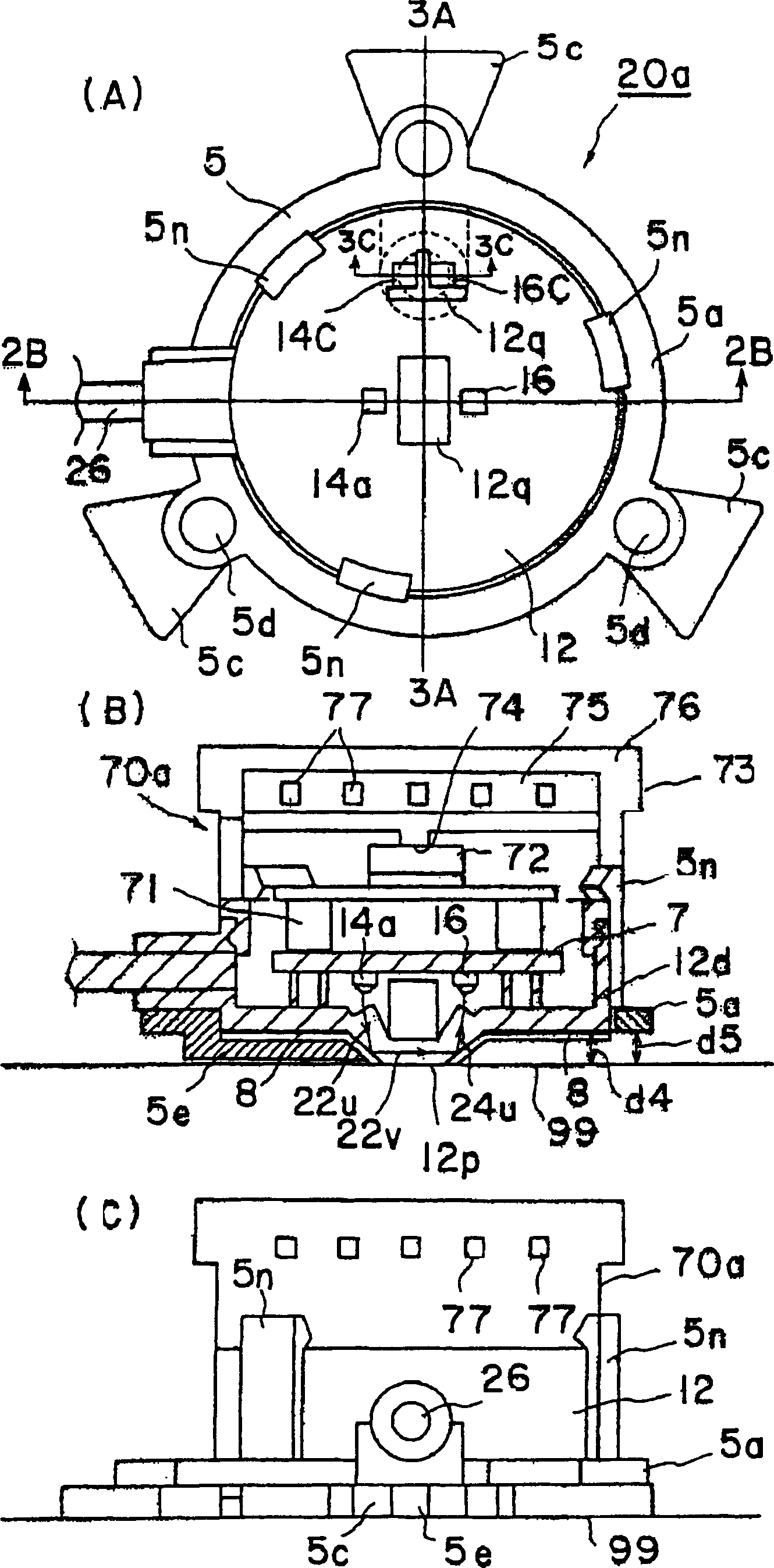

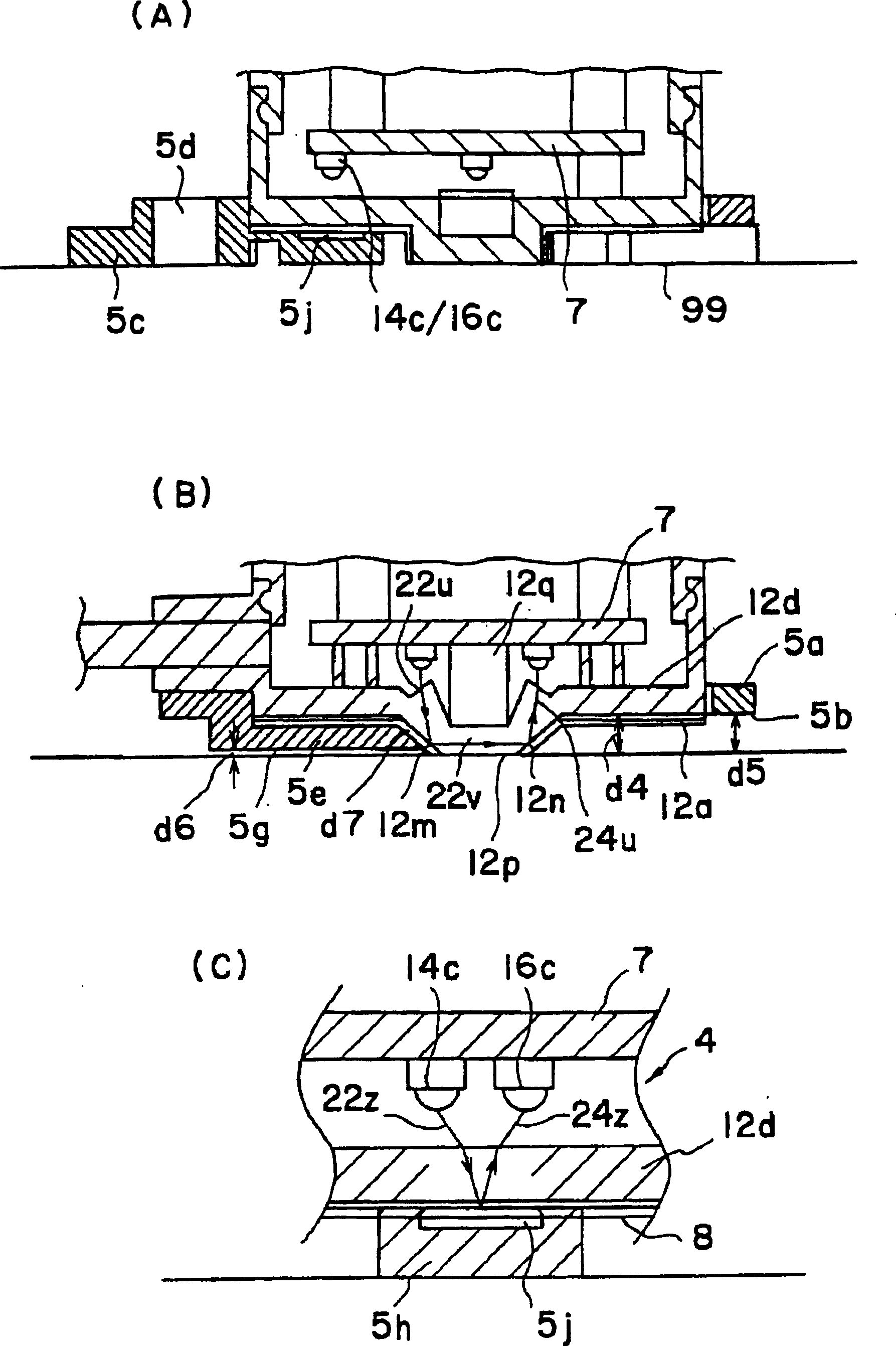

[0066] Below, refer to Figure 1 to Figure 6 , the case where the liquid leakage detection system of the present invention is applied to a coating and developing device for semiconductor wafers (hereinafter referred to as wafers) will be described.

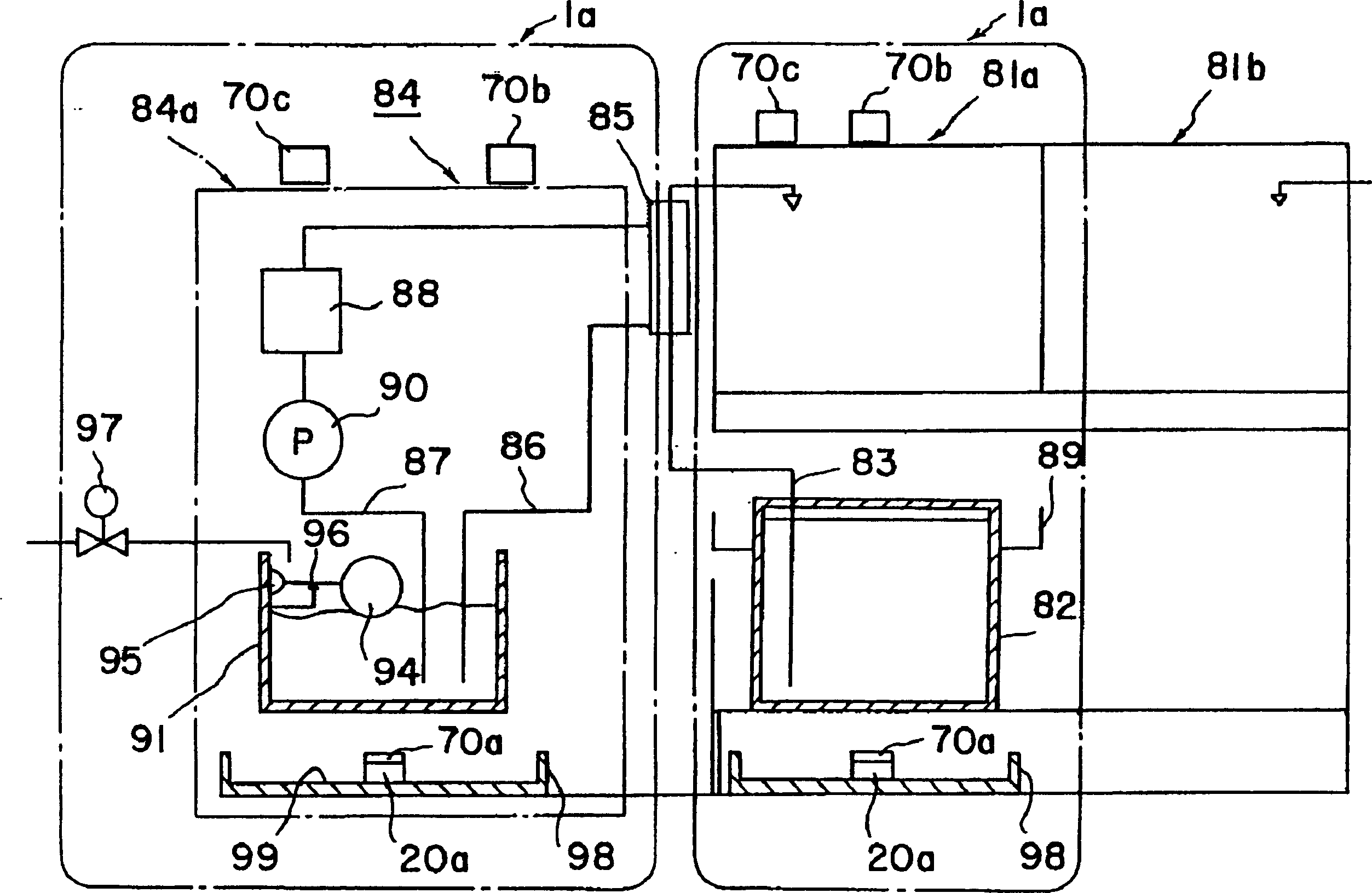

[0067] first, figure 1 It is an example of the liquid leakage detection system 1a which comprises the liquid leakage detection part (liquid leakage sensor) 20a of this invention by integrally forming the liquid leakage sensor part 20a and the alarm member 70a which includes the sounding part 72. is constructed using at least one leak sensor (in figure 1 However, on the same bottom surface and base surface with a large area, a plurality of liquid leakage sensors can also be dispersedly installed in multiple positions) as an example of the liquid leakage detection system 1a, the liquid leakage sensor has at least one The liquid leakage detection part in contact with the leakage liquid through the gas layer permeable to the leaka...

Embodiment 2

[0126] Second, with Figure 1 to Figure 6 Correspondingly expressed Figure 7 to Figure 9 Another embodiment of the liquid leakage detection system 1b and 1c is shown in which the liquid leakage detection part (liquid leakage sensor part) of the present invention is separated into a liquid leakage sensor main body 20b and an alarm part 70b including a sounding part. Numbered devices perform the same function, and, in Figure 7 In the liquid leakage detection system 1b, the liquid leakage sensor 20b and the alarm part 70b provided separately constitute an explosion-proof type liquid leakage detection system 1b through wireless signal relay. In addition, in the liquid leakage detection system 1c, the liquid leakage sensor 20b and The alarm unit 70b provided separately constitutes an explosion-proof liquid leakage detection system 1c relayed by wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com