Photocureable rapid shaping indirect manufacturing method for controllable microtube structure stand

A manufacturing method and light-curing technology, applied in medical science, special data processing applications, instruments, etc., can solve problems such as lack of mechanical strength, achieve convenient and accurate growth and survival, and be conducive to the effect of oxygen and nutrient supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

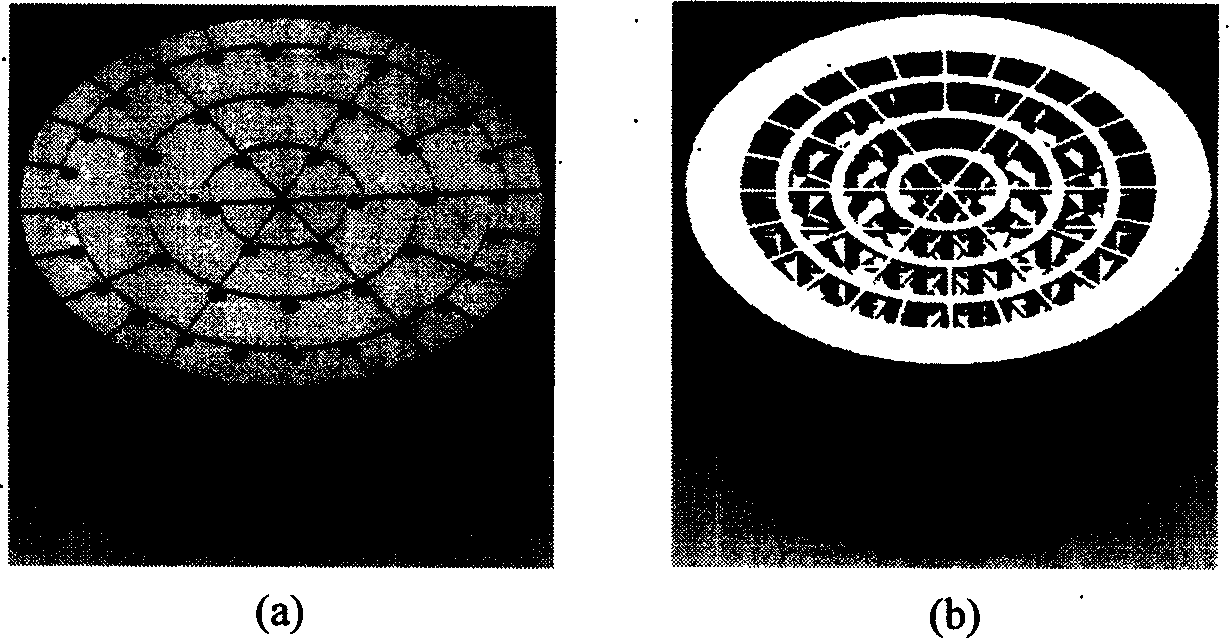

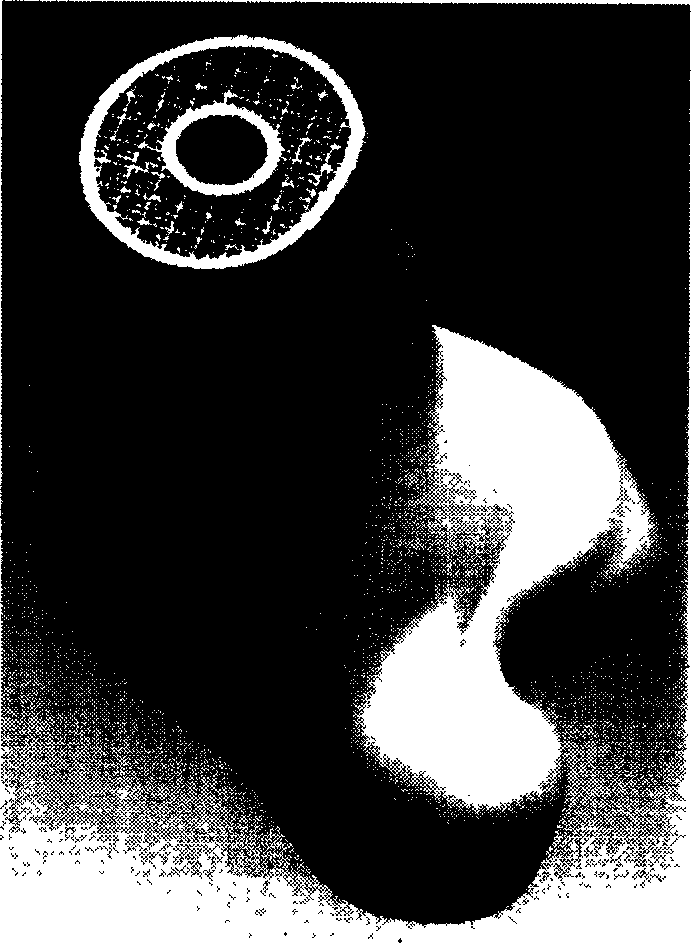

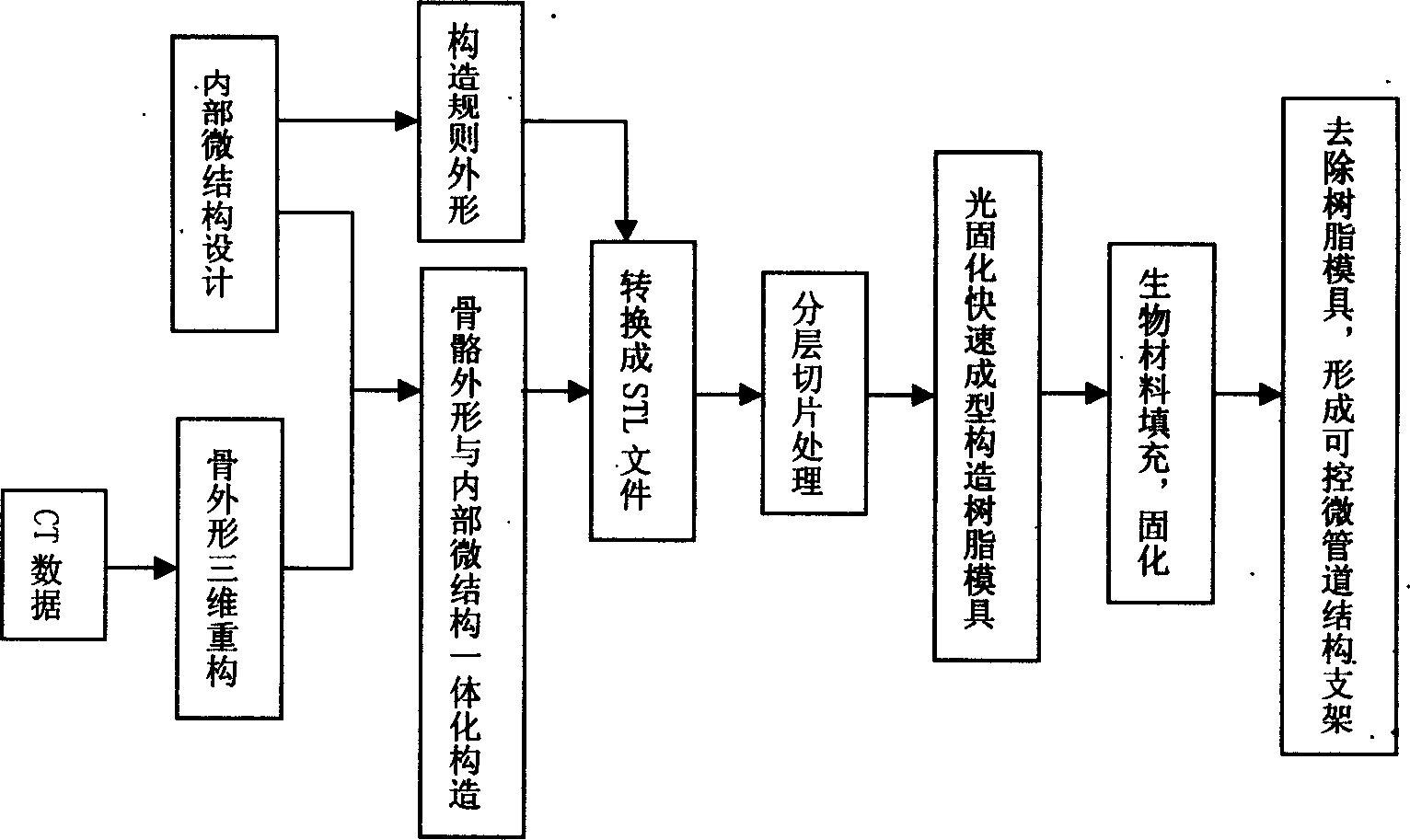

[0026] For pictures of the bionic scaffolds for the distal femur of dogs prepared by the invented method, see figure 2 , the process is as image 3 shown. According to the clinical CT data, after a series of image processing, the continuous CT images are input into the Mimics software in order to obtain the point cloud data of the distal femur of the dog, and store them in IGES format files, and then input the obtained point cloud data into the Surface The software performs surface reconstruction. Due to the complex shape of the joint surface of the distal femur, large curvature changes, and certain deviations in the obtained point cloud data, if only traditional faceting methods are used, such as: Loft, Sweep, Through Curve and Through CurveMesh, etc., cannot effectively construct high-quality joint surfaces. Therefore, the three-dimensional reconstruction of the joint surface is completed by using the two faceting methods of point data paste and freeform surface (fit free...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com