Method for determining parameters for rolling contact quenching dry hard machined workpiece

A technology of rolling contact and parameter selection, applied in metal processing mechanical parts, automatic control devices, electrical digital data processing, etc., can solve the problems that cannot provide scientific basis for the optimization of fine and hard dry cutting parameters of superhard material parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

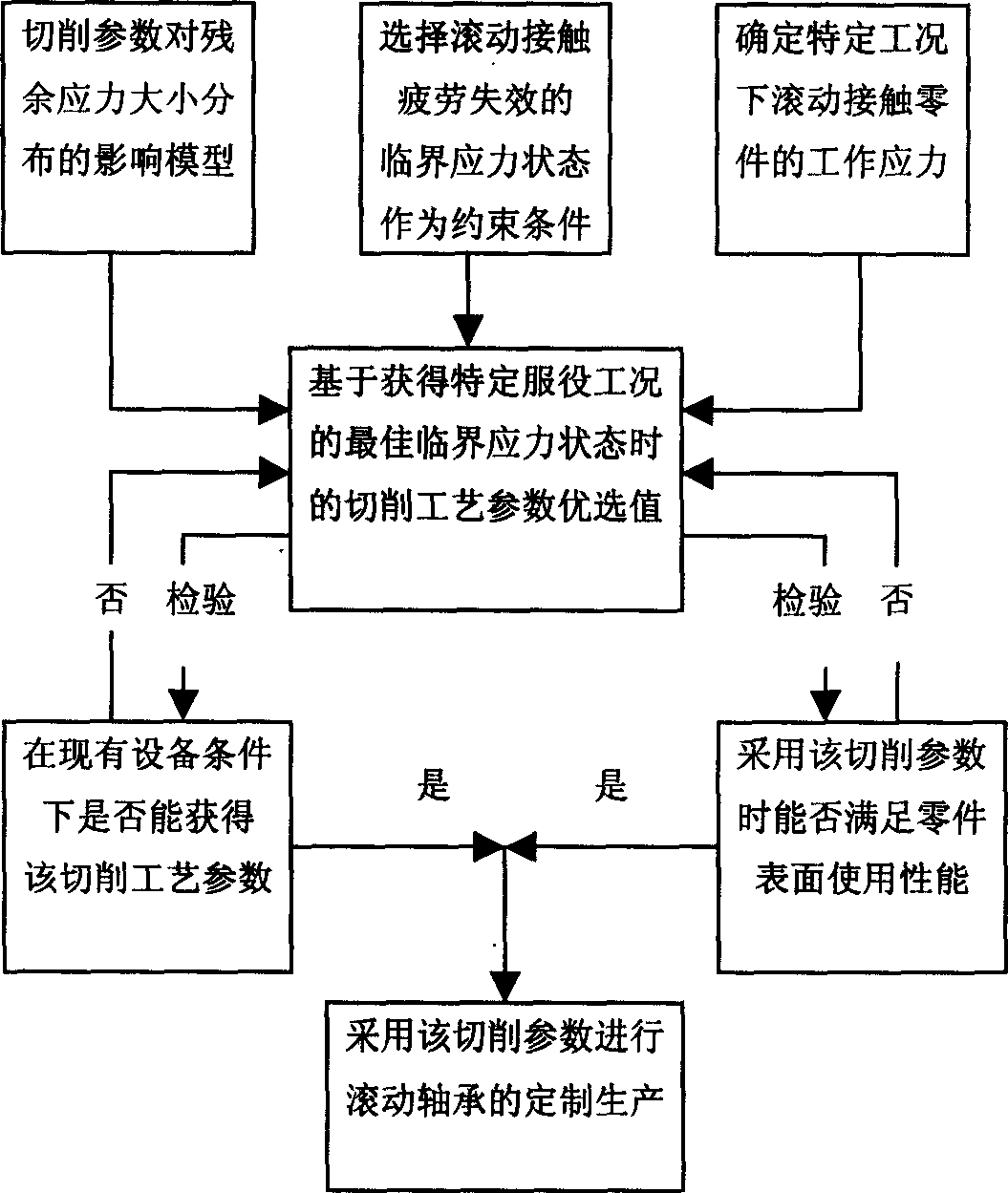

[0047] Such as figure 1 As shown, the customized production process of hardened rolling bearings: (1) Determine the working stress range according to the service conditions of specific rolling bearings (load, friction, load properties, etc.), and input them as initial values; (2) Determine the hardened The constraint conditions of dry cutting parameters, that is, the reasonable range of cutting speed, cutting depth, feed rate, tool wear, etc.; (3) Under the achievable process conditions, determine all the cutting process parameter sets that meet the surface accuracy requirements; ( 4) Determine the initial residual stress of the contact surface of the hardened rolling bearing in hard dry cutting under the set of all cutting process parameters that meet the requirements; The minimum stress is optimal, so the optimal combination of cutting process parameters is optimized. The service conditions of typical rolling bearings are shown in Table 1.

[0048] Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com