Electrochemical oxidation process for removing algae toxins from water

A technology for algal toxins and water removal, applied in chemical instruments and methods, electrochemical water/sewage treatment, separation methods, etc., can solve the problems of unreported algal toxins in water, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

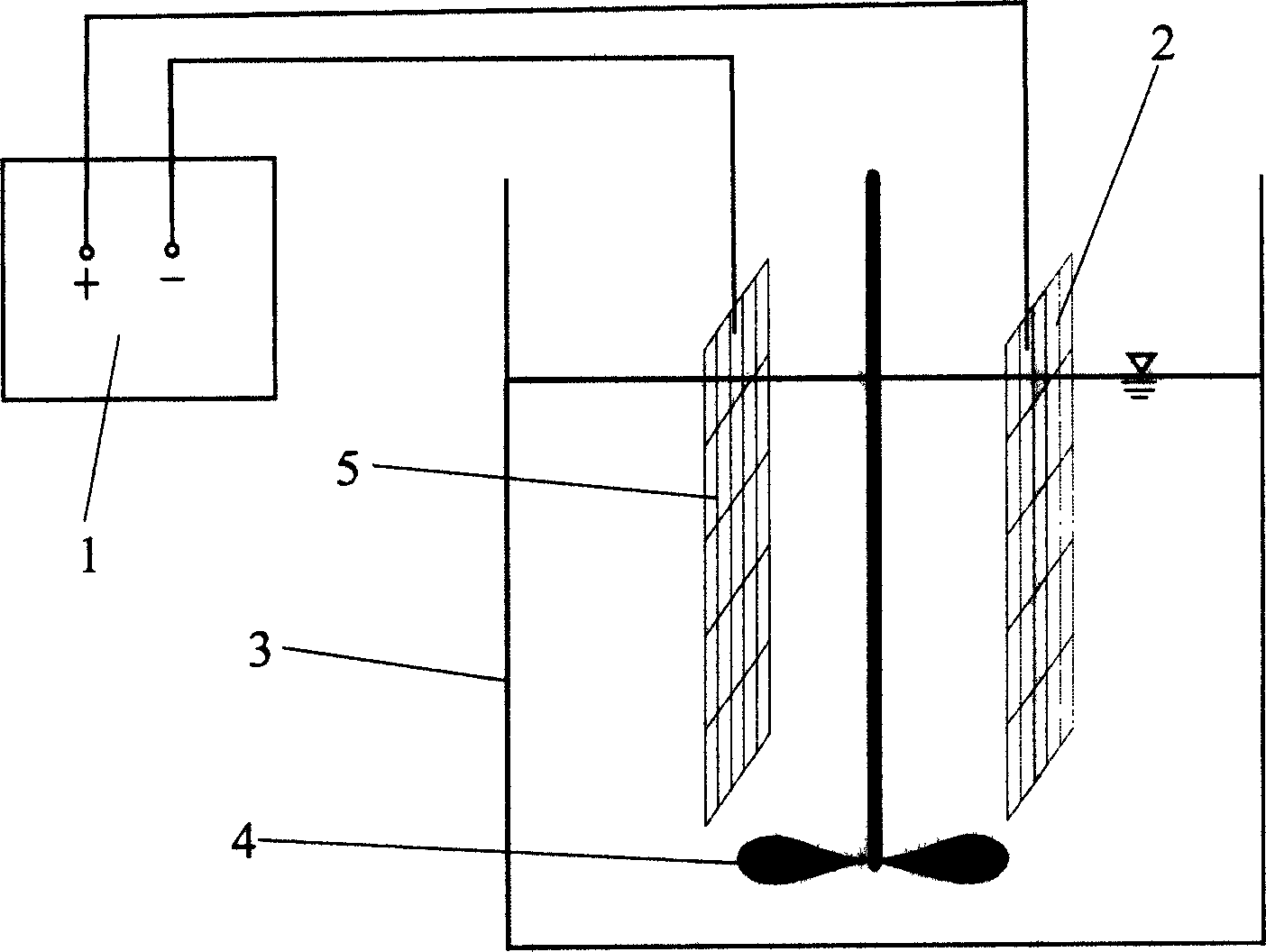

Image

Examples

Embodiment 1

[0025] Embodiment 1. Removal of different concentrations of algae toxins in raw water by electrochemical oxidation

[0026] Use high-purity water to prepare aqueous solutions containing algae toxins of different concentrations, and perform electrochemical treatment under the following conditions:

[0027] Algal toxin concentration: MCRR 12.58, 6.29, 3.14mg / L, MCLR 8.29, 4.15, 2.07mg / LNaCl initial concentration is 1.85mmol / L

[0028] pH=7.00

[0029] Current intensity I=60mA

[0030] Table 1 shows the changes in algal toxin concentration when treated at different times.

[0031] time, min

[0032] As can be seen from Example 1, the lower the initial concentration of algal toxins, the shorter the reaction time required for complete removal.

Embodiment 2

[0033] Example 2. Removal of algae toxins in raw water containing different concentrations of chloride ions by electrochemical oxidation

[0034] Use high-purity water to prepare algae toxin raw water containing different concentrations of chloride ions, and perform electrochemical treatment under the following conditions:

[0035] Initial concentration of chloride ion: 1.85, 20, 40mmol / L Cl -

[0036] Algal toxin concentration: MCRR 12.58mg / L, MCLR 8.29mg / L

[0037] pH=7.00

[0038] Current intensity I=60mA

[0039] After treatment for different time, the changes of algal toxin concentration are shown in Table 2.

[0040] It can be seen from Example 2 that with the increase of the concentration of chloride ions in the raw water, the reaction time required for the complete removal of algae toxins is shortened.

Embodiment 3

[0041] Example 3. Removal of algae toxins in raw water by electrochemical oxidation under different current intensities

[0042] Use raw water with a certain concentration of algae toxins to perform electrochemical treatment under the following conditions:

[0043] Current intensity I=40, 60, 80mA

[0044] NaCl initial concentration: 1.85 mmol / L

[0045] Algal toxin concentration: MCRR 12.58mg / L, MCLR 8.29mg / L

[0046] pH=7.00

[0047] The changes in algal toxin concentration after treatment for different time are shown in Table 3.

[0048] It can be seen from Example 3 that with the increase of the current intensity, the reaction time required for the complete removal of algae toxins is shortened.

[0049]

[0050]

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com